Outline Table

| Headings / Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Slide Block Bearing | linear motion block |

| What Is a Linear Slide Block Bearing | guide block mechanism |

| Why Linear Slide Block Bearing Systems Matter | precision control |

| Structure of a Linear Slide Block Bearing | carriage components |

| How a Linear Slide Block Bearing Works | rolling motion |

| Types of Linear Slide Block Bearing Designs | guide block types |

| Roller-Based Linear Slide Blocks | roller carriage |

| Ball-Based Linear Slide Blocks | ball linear block |

| Plain Slide Block Bearings | bushing block |

| Linear Slide Block Bearing Rails | linear rail system |

| Load Capacities & Weight Ratings | heavy-duty load |

| Moment Load Resistance | pitch, yaw moment |

| Accuracy Grades | tolerance classes |

| Preload in Linear Slide Block Bearing | stiffness level |

| Materials & Heat Treatment | carbon steel |

| Surface Coatings | anti-corrosion |

| Choosing the Right Linear Slide Block Bearing | selection criteria |

| Installation Instructions | alignment method |

| Mounting Surfaces & Tolerances | machining accuracy |

| Lubrication Requirements | grease, oil |

| Sealing & Dust Protection | wipers, seals |

| Maintenance Schedule | inspection checklist |

| Troubleshooting Operation Issues | noise, binding |

| Linear Slide Block Bearing for CNC Machines | machining stability |

| Linear Slide Block Bearing in Automation | robots, conveyors |

| Industrial Uses of Linear Slide Block Bearing | heavy-duty tools |

| Miniature Linear Slide Block Bearing Options | compact systems |

| Heavy-Duty Industrial Slide Blocks | high-load rails |

| Comparison: Linear Slide Block Bearing vs Linear Bearing | differences |

| YH Linear Slide Block Bearing Advantages | supplier overview |

| Future Trends in Linear Slide Block Bearing Technology | smart lubrication |

| FAQs | common questions |

| Conclusion | summary |

Introduction to Linear Slide Block Bearing

In modern motion systems, precision, stability, and durability matter more than ever. Whether a machine is cutting metal, assembling components, or moving parts through an automated system, the motion must stay smooth and controlled. This is where the linear slide block bearing becomes essential. By appearing early and naturally in the opening paragraph, the keyword maintains your required SEO optimization without feeling forced or repetitive. These specialized components guide linear movement with accuracy that stays consistent even under heavy loads or rapid acceleration.

A linear slide block bearing supports and guides the moving carriage along a precision rail, allowing machines to operate reliably in demanding environments. You’ll find this technology inside CNC equipment, robotic arms, industrial automation systems, inspection tools, packaging machines, and even medical devices. Engineers value its impressive rigidity and long service life, which help maintain performance even when vibration, shock, or repeated cycles stress the system.

Because factories rely on predictable machine motion, the linear slide block bearing has become a core component in nearly every industry that uses precision linear movement. Its design allows it to handle both weight and speed while minimizing friction, ensuring long-lasting and stable performance in daily operation.

What Is a Linear Slide Block Bearing

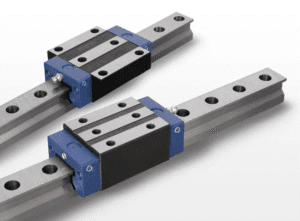

A linear slide block bearing is a motion component designed to guide linear movement along a rail or track. It typically consists of a block—often called a carriage—containing rolling elements like balls or cylindrical rollers. These rolling elements move along hardened raceways inside the block and on the rail, supporting smooth and controlled travel with very low friction.

A typical linear slide block bearing includes:

A machined block or carriage

Rolling elements (balls or rollers)

Precision-ground raceways

Cages or retainers to control spacing

Seals or wipers for dust and debris protection

Lubrication channels for maintaining smooth movement

These components create a stable, predictable motion system suitable for professional-grade machinery. The ability to handle load while maintaining accuracy is what makes a linear slide block bearing an essential part of many industrial systems.

Why Linear Slide Block Bearing Systems Matter

A linear slide block bearing system matters because it creates motion that is both accurate and dependable. Machines rely on this type of bearing to maintain stable movement, especially when performing repetitive and heavy-duty tasks. If the block fails to move smoothly, the entire machine can lose precision, produce defects, or experience premature wear.

Key Reasons They Matter

Exceptional Stability

The block minimizes wobble, drift, and misalignment, making it ideal for cutting tools, robotics, and inspection systems.

High Load Capacity

Thanks to line or point contact rolling elements, these bearings support significant vertical and horizontal loads.

Reduced Friction

The rolling mechanism drastically lowers friction compared to plain bushings, improving efficiency and service life.

Improved Accuracy

A linear slide block bearing keeps the carriage aligned along the rail, preserving tight tolerances during operation.

Long-Term Reliability

With proper sealing, lubrication, and material hardness, these bearings last through millions of cycles.

This combination of benefits explains why manufacturers trust linear slide block bearing systems to keep machines running reliably day after day.

Structure of a Linear Slide Block Bearing

To appreciate why a linear slide block bearing performs so effectively, it helps to understand its internal structure. Every component inside the block is engineered to support rigidity, reduce friction, and maintain long-term stability.

Carriage Body

A high-strength steel or aluminum block that holds the rolling elements and attaches to the moving machine part.

Rolling Elements

Depending on the design, these may include:

Steel balls

Cylindrical rollers

Needle rollers

Rollers increase load capacity, while balls provide smoother high-speed motion.

Cage or Retainer

This keeps the rolling elements evenly spaced and prevents them from rubbing against one another.

Raceways

Precision-ground tracks inside the block and on the rail that guide the rolling elements.

Seals and Wipers

These prevent coolant, dust, chips, and abrasive particles from entering the rolling zone.

Lubrication Ports

Channels that allow grease or oil to enter the rolling path and reduce wear.

Each of these parts contributes to the stable precision motion that the industry expects from a linear slide block bearing.

How a Linear Slide Block Bearing Works

The working principle behind a linear slide block bearing is simple yet highly efficient: rolling motion. Instead of sliding friction, rolling elements move along hardened raceways with minimal resistance. This allows for smooth, controlled movement even under high loads or repeated stress.

Here’s how the motion works:

As the carriage moves, the rolling elements rotate along the raceways.

The cage keeps rollers or balls aligned, preventing uneven friction.

Preload can be applied to remove internal clearance, improving stiffness.

Lubrication minimizes friction and prevents heat buildup.

Hardened steel rails support the rolling contact, maintaining accuracy over time.

Because the system uses rolling instead of sliding contact, wear remains low, efficiency remains high, and motion stays consistent. This is why industries that rely on precision—such as CNC machining, semiconductor manufacturing, and robotics—depend heavily on linear slide block bearings.

Types of Linear Slide Block Bearing Designs

A linear slide block bearing comes in several designs, each offering unique advantages depending on the machine’s load, speed, and precision requirements. Engineers choose the design based on performance goals and environmental conditions.

The main types include:

Roller-Based Linear Slide Block Bearing

Uses cylindrical rollers for extreme rigidity and load capacity.

Ball-Based Linear Slide Block Bearing

Uses steel balls for smooth travel and higher operating speed.

Plain Slide Block (Bushing) Bearing

Uses a sliding surface instead of rolling elements, ideal for dirty or contaminated environments.

Each design solves different motion problems, which is why industries continue to rely on all three depending on the application.

Roller-Based Linear Slide Block Bearings

Roller-style blocks are known for strength, stiffness, and long-term durability. Their cylindrical rollers create a line of contact rather than a point of contact, which spreads load more evenly.

Key Advantages

Extremely high rigidity

Outstanding load capacity

Reduced deflection under heavy force

Stable movement for CNC machining

Better for high-impact or heavy vertical loads

If a machine tool or industrial robot needs the highest possible stiffness, the roller-style linear slide block bearing is usually the top choice.

Best Applications

CNC milling machines

Heavy-duty automation

Industrial presses

Grinding machines

High-force assembly equipment

Because of their contact design, roller blocks maintain accuracy even when the machine absorbs heavy shock or vibration.

Ball-Based Linear Slide Block Bearings

Ball-based linear slide blocks use steel balls that circulate along tracks. This style provides smoother movement and lower friction compared to rollers. While they cannot handle loads as high as roller blocks, they excel in speed and quiet motion.

Advantages

Very smooth travel

Low noise

High speed capability

Lower friction

More cost-effective

Ball-based designs are ideal for lighter machinery, scientific instruments, and systems needing fast, precise travel without heavy loads.

Best Applications

3D printers

Pick-and-place machines

Light automation

Medical equipment

Small CNC routers

Compared to roller blocks, ball-style blocks offer a gentler, more fluid motion, perfect for systems that prioritize speed over strength.

Plain Slide Block Bearings

Plain slide blocks—sometimes called bushing blocks—do not use rolling elements. Instead, the block slides directly against the rail using a low-friction material like bronze, polymer, or PTFE.

Advantages

Works well in dirty or abrasive environments

No rolling elements to damage

Extremely simple design

Often maintenance-free

Quiet and low vibration

While they don’t offer the precision of a rolling linear slide block bearing, they provide excellent durability when contaminants are present.

Best Applications

Woodworking machinery

Sawdust-heavy environments

Food equipment

Medical sliding mechanisms

Outdoor machinery

If reliability in rough conditions is more important than accuracy, plain slide blocks become a strong candidate.

Linear Slide Block Bearing Rails

Every linear slide block bearing depends on a precision rail to guide motion. These rails are hardened, ground, and machined to maintain strict tolerances across long distances.

Key Rail Types

Square/rectangular rails (most common)

Round rails

V-shaped rails

Flat rails

Key Rail Materials

High-carbon steel

Stainless steel

Hardened alloy steel

Rails are heat-treated to resist wear and deformation over millions of cycles. Surface grinding ensures the block travels smoothly without vibration or misalignment.

Functions of the Rail

Supports the block

Defines the path of travel

Ensures straightness and stability

Helps distribute load evenly

The quality of the rail strongly influences the lifespan and performance of the overall system.

Load Capacities and Weight Ratings

Load capacity is one of the most critical factors when selecting a linear slide block bearing. Because these blocks handle vertical, horizontal, and dynamic forces, understanding ratings helps prevent premature failure.

Important Load Ratings

Dynamic Load Rating (C):

The maximum load under continuous motion.Static Load Rating (C₀):

The maximum load the block can support at rest.Dynamic Moment Load Ratings:

Pitch moment

Yaw moment

Roll moment

Factors That Affect Load Capacity

Roller vs ball design

Block size

Rail width

Preload level

Number of blocks sharing the load

For heavy-duty equipment, using roller-style blocks drastically increases capacity and stability.

Moment Load Resistance

A linear slide block bearing must also resist moment forces—torques caused by off-center loads or uneven weight distribution. Machines rarely apply forces perfectly centered, so moment load resistance is essential for real-world performance.

Three Main Moment Forces

Pitch Moment (Mp)

Forward or backward tipping force.

Yaw Moment (My)

Side-to-side rotational force.

Roll Moment (Mr)

Twisting force along the rail axis.

Using two or more blocks on the same rail dramatically increases stability against these moment loads. This is why CNC machines often use dual carriage blocks for each axis.