Outline

| Heading | Subtopics Covered |

|---|---|

| Introduction to Linear Rail Bearings | Importance, function, and role in modern machinery |

| What Are Linear Rail Bearings? | Definition, design overview, and fundamental concept |

| The Working Principle of Linear Rail Bearings | Rolling motion mechanics and load distribution |

| Key Components of Linear Rail Bearings | Rails, blocks, balls, retainers, seals, and end caps |

| Different Types of Linear Rail Bearings | Ball-type, roller-type, miniature, and self-aligning systems |

| Materials Used in Linear Rail Bearings | Stainless steel, chrome steel, ceramics, and composites |

| Advantages of Linear Rail Bearings | Precision, smoothness, load capacity, and longevity |

| Limitations of Linear Rail Bearings | Cost, contamination sensitivity, and alignment requirements |

| Applications of Linear Rail Bearings | Robotics, CNC machining, 3D printing, and automation |

| Design Considerations for Linear Rail Bearings | Load rating, stroke length, speed, and environment |

| Installation and Alignment Best Practices | Step-by-step mounting, alignment, and torque guidelines |

| Lubrication and Maintenance of Linear Rail Bearings | Grease types, cleaning intervals, and lubrication methods |

| Common Problems and Troubleshooting Tips | Noise, friction, vibration, and wear issues |

| Linear Rail Bearings vs Linear Bushings | Differences in structure, precision, and performance |

| Performance Optimization Techniques | Preload settings, vibration control, and damping systems |

| Innovations in Linear Rail Bearing Technology | Smart bearings, hybrid materials, and self-lubrication |

| Environmental and Sustainability Aspects | Eco-lubricants, recyclable materials, and energy efficiency |

| Quality Standards and Testing for Linear Rail Bearings | ISO certification, endurance, and dimensional accuracy tests |

| Cost Analysis and Lifespan Expectations | Price factors, ROI, and service life |

| Case Study: Linear Rail Bearings in Industrial Robots | Real-world implementation and benefits |

| The Future of Linear Rail Bearings in Automation | Smart factories, AI integration, and predictive monitoring |

| FAQs About Linear Rail Bearings | Common questions and professional insights |

| Conclusion: Why Linear Rail Bearings Define Precision Motion | Summary and future potential |

Introduction to Linear Rail Bearings

In the world of precision motion engineering, linear rail bearings stand as silent heroes. These advanced motion components ensure accurate, stable, and low-friction linear movement across machines and automation systems. Whether it’s a high-speed CNC machine, a medical imaging device, or a robotic arm, the performance of a system often depends on the quality and precision of its linear rail bearings.

The evolution of linear rail bearings has transformed mechanical engineering — enabling higher efficiency, smoother motion, and reduced wear compared to traditional sliding systems. Today, they are the foundation of automation, robotics, and mechatronic innovation.

What Are Linear Rail Bearings?

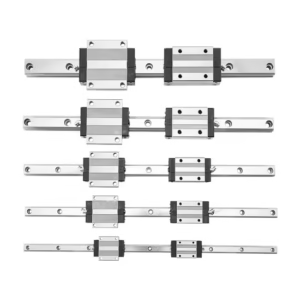

A linear rail bearing is a mechanical device designed to guide motion along a straight line with high accuracy and minimal friction. It consists of two main components — a guide rail and a bearing block (also called a carriage or slider). Inside the block, small hardened steel balls or rollers circulate as the rail moves, supporting both dynamic and static loads.

This rolling contact mechanism allows precise motion without binding or uneven resistance, making linear rail bearings ideal for repetitive and high-speed applications where precision is critical.

The Working Principle of Linear Rail Bearings

The magic of linear rail bearings lies in their rolling mechanism. When the block moves along the rail, the internal ball or roller elements circulate continuously within the block’s grooves. This design ensures that the load is evenly distributed over multiple contact points, minimizing localized stress and friction.

The recirculating motion creates a self-sustaining, smooth glide that reduces wear and ensures long operational life. With the addition of preloaded elements and precision-ground surfaces, linear rail bearings achieve micron-level accuracy in linear motion.

Key Components of Linear Rail Bearings

Every linear rail bearing system includes several precisely engineered components:

Guide Rail: The stationary track providing the motion path.

Bearing Block (Carriage): The moving part that glides along the rail.

Rolling Elements: Balls or rollers that facilitate low-friction motion.

Retainer (Cage): Maintains spacing and circulation of rolling elements.

Seals: Protect the internal mechanism from dust and debris.

End Caps: Guide recirculating elements back into motion paths.

Together, these parts deliver the precision and durability that modern machinery demands.

Different Types of Linear Rail Bearings

There are multiple types of linear rail bearings, each optimized for specific performance and environmental conditions:

Ball-Type Linear Rails: Offer smooth, low-friction motion and high speed.

Roller-Type Linear Rails: Use cylindrical rollers for higher load-bearing capacity.

Miniature Linear Rails: Compact systems for micro-mechanical or electronic devices.

Self-Aligning Rails: Tolerate slight installation misalignments.

Flanged Linear Rails: Simplify mounting and enhance stability.

Choosing the right type depends on factors such as precision requirements, load size, and environmental exposure.

Materials Used in Linear Rail Bearings

The performance and longevity of linear rail bearings rely heavily on material quality. Common materials include:

Stainless Steel: Resists corrosion and is ideal for cleanroom environments.

Chrome Steel (GCr15): Provides hardness and cost efficiency.

Ceramic Balls: Lightweight, durable, and ideal for high-speed applications.

Aluminum Housings: Reduce system weight without compromising strength.

Advanced designs also include hybrid materials combining steel races with ceramic balls for enhanced performance and reduced friction.

Advantages of Linear Rail Bearings

Linear rail bearings bring numerous advantages that make them indispensable in modern machinery:

High Precision: Achieves accurate linear positioning with minimal deviation.

Low Friction: Rolling contact reduces energy loss and wear.

High Rigidity: Ensures stability under heavy or dynamic loads.

Durability: Long service life with proper lubrication.

Compact Design: Efficient space utilization for modern automation systems.

Low Noise: Quiet operation due to smooth rolling elements.

These benefits explain why linear rail bearings dominate industries that require precision motion.

Limitations of Linear Rail Bearings

Despite their advantages, linear rail bearings have certain limitations to consider:

Higher Initial Cost: Precision engineering increases upfront investment.

Installation Sensitivity: Requires exact alignment for optimal performance.

Contamination Risk: Dust or debris can impair motion or cause wear.

Lubrication Dependency: Insufficient lubrication may lead to early failure.

Fortunately, innovations such as self-lubricating systems and sealed units have addressed many of these challenges.

Applications of Linear Rail Bearings

Linear rail bearings are found in almost every modern precision device. Common applications include:

CNC Machines: Enables precise cutting and tool movement.

Robotics: Facilitates smooth, repeatable arm and gantry motion.

3D Printers: Maintains accurate movement during printing.

Medical Equipment: Used in scanning tables, imaging systems, and automation tools.

Semiconductor Manufacturing: Ensures micron-level movement control.

Packaging and Automation Lines: Provides fast, consistent movement.

From aerospace to automotive assembly, linear rail bearings drive the world’s most demanding motion systems.

Design Considerations for Linear Rail Bearings

When selecting or designing a linear rail bearing system, engineers must evaluate:

Load Capacity (Dynamic & Static): Must handle operational stresses.

Travel Stroke Length: Determines motion range.

Speed and Acceleration: Influences bearing type and lubrication.

Operating Environment: Temperature, dust, or moisture can affect performance.

Preload Requirements: Balances stiffness and smoothness.

A well-matched design ensures reliability and longevity in high-precision applications.

Installation and Alignment Best Practices

Proper installation is key to achieving smooth motion and extended life.

Steps to install linear rail bearings correctly:

Clean surfaces to remove dust or oil.

Align the rail using a straight edge or laser guide.

Gradually tighten mounting bolts from the center outward.

Ensure uniform torque distribution.

Test carriage movement for smoothness before full operation.

Incorrect alignment can cause binding, noise, and premature wear.

Lubrication and Maintenance of Linear Rail Bearings

Lubrication ensures reliable operation and longevity.

Best practices include:

Apply lithium-based grease or synthetic oil depending on load and speed.

Schedule re-lubrication every 6–12 months under normal conditions.

Use cleanroom-compatible lubricants for sterile environments.

Inspect regularly for noise, resistance, or uneven motion.

A consistent lubrication routine can increase lifespan by up to 300%.

Common Problems and Troubleshooting Tips

Common performance issues with linear rail bearings include:

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| Rough movement | Dirt or debris | Clean rail and re-lubricate |

| Noise or vibration | Misalignment or dryness | Re-align and lubricate |

| Wear marks | Overload or contamination | Reduce load, use seals |

| Loosened rails | Improper installation | Retighten using torque guide |

Early detection and maintenance prevent costly downtime and replacement.

Linear Rail Bearings vs Linear Bushings

| Feature | Linear Rail Bearings | Linear Bushings |

|---|---|---|

| Motion Type | Rolling contact | Sliding contact |

| Friction Level | Very low | Moderate |

| Load Capacity | High | Lower |

| Precision | Excellent | Good |

| Maintenance | Minimal | Moderate |

| Cost | Higher | Lower |

While bushings suit basic systems, linear rail bearings excel in precision, speed, and load-bearing performance.

Performance Optimization Techniques

Engineers enhance linear rail bearing systems through:

Preload Adjustments: Eliminates backlash and improves stiffness.

Vibration Dampers: Reduces resonance and improves accuracy.

Ceramic Rolling Elements: Enhances high-speed performance.

Protective Covers: Prevents contamination in dusty environments.

Optimization boosts accuracy, smoothness, and system longevity.

Innovations in Linear Rail Bearing Technology

Modern advancements include:

Smart Bearings: Integrated sensors monitor load, temperature, and wear.

Self-Lubricating Systems: Deliver consistent lubrication without maintenance.

Nano-Coatings: Reduce corrosion and friction.

Hybrid Materials: Combine steel rails with ceramic rollers for superior performance.

These innovations redefine reliability and efficiency in motion control systems.

Environmental and Sustainability Aspects

Sustainability in linear rail bearing manufacturing focuses on:

Using recyclable steel alloys and eco-lubricants.

Implementing energy-efficient manufacturing.

Designing longer-lasting components to reduce waste.

Reducing lubricant pollution through sealed bearing systems.

The green evolution of linear bearings aligns with global efforts for sustainable engineering.

Quality Standards and Testing for Linear Rail Bearings

Top manufacturers follow stringent quality standards, including:

ISO 9001 & ISO 281 Certifications.

Hardness and Fatigue Tests for durability.

Dimensional Accuracy Checks using precision metrology tools.

Endurance Testing under real-world load cycles.

These procedures guarantee consistent performance, safety, and reliability.

Cost Analysis and Lifespan Expectations

While linear rail bearings may require a higher initial investment, their long service life and minimal maintenance make them highly cost-effective.

High-quality models can last over 50,000 hours or 10 million linear cycles under optimal conditions, providing an excellent return on investment.

Case Study: Linear Rail Bearings in Industrial Robots

In industrial robotics, linear rail bearings play a pivotal role in ensuring precise, stable motion. One automotive manufacturer reported a 30% improvement in assembly precision and a 25% reduction in maintenance downtime after upgrading to hybrid ceramic linear rails.

Their integration boosted throughput and reliability in robotic arms and gantry systems — a testament to their engineering excellence.

The Future of Linear Rail Bearings in Automation

The future belongs to smart, connected systems. The next generation of linear rail bearings will feature:

AI-driven predictive maintenance.

IoT-enabled performance tracking.

Carbon-neutral manufacturing.

Digital twins for motion simulation.

As automation evolves, these bearings will continue to define precision and reliability in intelligent manufacturing systems.

FAQs About Linear Rail Bearings

What is the main function of a linear rail bearing?

It provides precise, low-friction linear motion for mechanical systems.

How long do linear rail bearings last?

Typically between 20,000–50,000 hours depending on conditions.

Do they require lubrication?

Yes, regular lubrication minimizes wear and friction.

Can linear rail bearings handle vertical loads?

Yes, but always verify the manufacturer’s rated load capacity.

What causes bearing noise?

Misalignment, dirt, or insufficient lubrication are common causes.

Are ceramic linear bearings better than steel ones?

They offer lower friction and higher speed but at a higher cost.

Conclusion: Why Linear Rail Bearings Define Precision Motion

The linear rail bearing is more than a mechanical component — it’s the backbone of modern automation. From the smallest robotics systems to massive industrial machines, it enables fluid, accurate, and reliable motion that defines efficiency and innovation.

With constant advancements in materials, coatings, and smart technology, linear rail bearings will continue to push the limits of precision engineering, making them indispensable in the next generation of intelligent motion systems.

Suggested Internal Links

[Understanding Linear Motion Systems]

[Best Practices for Bearing Lubrication]

[Choosing Between Ball and Roller Rails]