Introduction to Guide Rails

Imagine driving on a busy highway and suddenly veering off course. The barrier that stops you from tumbling into danger is a guide rail—a sturdy safeguard silently doing its job. From highways to factories, guide rails are everywhere, keeping people safe, machinery aligned, and systems efficient. They don’t often get the spotlight, yet without them, modern infrastructure and industries would be far riskier.

Over the years, guide rails have transformed from simple wooden fences to advanced metal and composite barriers with energy-absorbing designs. They’re no longer just roadside features but integral components in industries, robotics, automation, and architecture.

This article dives deep into the world of guide rails—their types, materials, applications, and future innovations. By the end, you’ll understand why these silent protectors are more important than ever.

What are Guide Rails?

At the simplest level, guide rails are safety structures or guiding mechanisms that control movement and direction. They may be physical barriers, like those along roadsides, or precision components in machinery ensuring accuracy.

Core functions of guide rails:

Containment: Preventing vehicles, objects, or people from leaving safe paths.

Guidance: Directing movement in a controlled manner.

Protection: Absorbing shock, reducing damage, and saving lives.

Materials used in guide rails include:

Steel (most common for roads and heavy-duty applications)

Aluminum (lightweight and corrosion-resistant)

Composite materials (eco-friendly and flexible)

Plastic (mainly in industrial and conveyor systems)

These features make guide rails indispensable across industries and public safety systems.

Types of Guide Rails

Guide rails come in different shapes, sizes, and strengths depending on where they are used.

Common types include:

Roadside guide rails: Installed on highways, bridges, and roadsides to prevent accidents.

Industrial guide rails: Used in conveyor systems and assembly lines to keep products aligned.

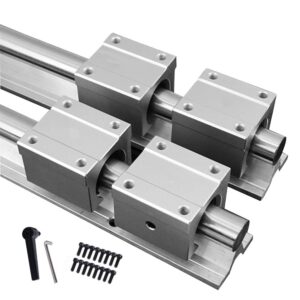

Machine guide rails: Precision components in CNC machines, elevators, and escalators.

Each type has unique functions, but they all serve the same purpose: keeping movement safe and controlled.

Road Safety and Guide Rails

Roadside guide rails are perhaps the most familiar. They run along highways, sharp bends, and bridges, acting as guardians against crashes.

Key roles in road safety:

Preventing vehicles from falling off elevated structures.

Reducing accident severity by absorbing crash energy.

Controlling the redirection of vehicles during impact.

In urban areas, guide rails are also found near pedestrian zones and intersections to protect people. Without them, road accidents would result in far more fatalities.

Industrial Guide Rails

Factories and warehouses depend on guide rails just as much as highways do.

Applications include:

Conveyor belts: Keeping packages, bottles, and products aligned.

Assembly lines: Ensuring smooth product flow.

Robotics: Providing precise direction for automated arms and vehicles.

Industrial guide rails reduce errors, increase efficiency, and keep workers safe from moving parts. They might not be visible to consumers, but they are essential in delivering the products we use daily.

Guide Rails in Machinery

Machinery, especially precision tools, relies on guide rails to maintain accuracy.

Examples:

CNC machines: Rails guide cutting tools with micrometer-level precision.

Heavy equipment: Hydraulic machines use rails to direct movement.

Elevators and escalators: Rails keep cabins and steps aligned, ensuring passenger safety.

Without guide rails, machinery would wear down quickly, and safety would be compromised.

Materials for Guide Rails

Different environments require different materials.

Most common materials:

Steel: Durable and strong, perfect for highways and heavy industries.

Aluminum: Lightweight and corrosion-resistant, often used in architecture.

Plastic: Common in conveyor belts, lightweight and easy to replace.

Composite materials: Growing in popularity due to sustainability and flexibility.

Choosing the right material depends on expected loads, environmental conditions, and budget.

Design Considerations

Designing guide rails requires balancing safety, cost, and efficiency. Engineers must consider:

Load capacity: How much weight or force the rail must handle.

Durability: Resistance against corrosion, weather, and wear.

Flexibility: Ability to absorb energy during impacts.

Maintenance needs: Ease of inspection and replacement.

A poorly designed guide rail could fail at a critical moment, leading to accidents.

Installation of Guide Rails

Proper installation determines performance.

Steps for roadside installation:

Site preparation and soil testing.

Setting posts at correct depths.

Mounting rails with precise spacing.

Conducting safety inspections.

Factory setup involves:

Aligning rails with conveyor belts.

Securing them with bolts and clamps.

Testing for smooth product flow.

Installation must follow safety regulations to ensure reliability.

Maintenance of Guide Rails

Guide rails last for years but require care.

Maintenance practices include:

Regular inspections for rust, cracks, or dents.

Replacing damaged sections immediately.

Applying protective coatings to prevent corrosion.

Checking alignment in machinery.

Neglecting maintenance can turn guide rails from lifesavers into hazards.

Advantages of Guide Rails

The benefits are significant:

Enhanced safety for drivers, workers, and pedestrians.

Durability with proper materials and maintenance.

Cost efficiency by reducing accidents and equipment damage.

Versatility across industries, transport, and architecture.

In essence, they are small investments with huge returns.

Disadvantages of Guide Rails

Like everything, guide rails have drawbacks:

High installation costs for highways and large factories.

Space requirements in urban settings.

Environmental concerns from steel and plastic production.

However, innovations are reducing these disadvantages through eco-friendly designs.

Innovations in Guide Rails

Technology is reshaping guide rails.

Recent developments include:

Smart guide rails with sensors to monitor crashes.

Energy-absorbing rails that reduce accident severity.

Eco-friendly materials made from recycled composites.

These innovations make guide rails not only safer but also more sustainable.

Guide Rails in Transportation

Beyond roads, guide rails are crucial in transport systems:

Railways: Keeping trains aligned.

Airports: Directing baggage conveyors.

Ports: Protecting docking areas.

Each system adapts guide rail designs to unique challenges.

Comparison with Guardrails

Many confuse guide rails with guardrails. While similar, they have differences.

Guide rails: Primarily direct movement and alignment.

Guardrails: Focus more on blocking or containing vehicles.

Both are essential, often working hand-in-hand.

Guide Rails in Architecture

Modern buildings also use guide rails:

Elevators: Ensuring vertical alignment.

Escalators: Guiding step movement.

Balconies: Serving as protective railings.

Here, design must blend functionality with aesthetics.

Environmental Impact of Guide Rails

Manufacturing steel and plastics raises environmental concerns. Yet, sustainability efforts are underway:

Recycling old rails.

Using eco-friendly coatings.

Developing biodegradable composites.

This reduces the carbon footprint while maintaining safety.

Cost of Guide Rails

Costs vary by material and application.

Factors influencing cost:

Material type (steel is more expensive than plastic).

Installation complexity.

Maintenance requirements.

Though costly upfront, guide rails often save money by preventing larger losses.

Safety Standards and Regulations

Guide rails must meet strict safety standards.

Examples:

AASHTO (US): Governs highway rails.

EN Standards (Europe): Cover industrial rails.

Local codes: Vary by country and application.

Compliance ensures reliability and reduces liability risks.

Guide Rails in Automation

Automation thrives on guide rails.

Applications include:

Robotic arms in factories.

Automated guided vehicles in warehouses.

Conveyor systems in logistics.

Guide rails ensure precision, safety, and efficiency in modern automated environments.

Case Studies of Guide Rail Use

Highways in Japan: Advanced energy-absorbing guide rails cut accident deaths significantly.

Factories in Germany: Conveyor guide rails reduced downtime by 30%.

Skyscrapers in Dubai: Elevator guide rails support some of the world’s fastest lifts.

These examples highlight their global importance.

Future of Guide Rails

Tomorrow’s guide rails will be smarter and greener.

Expectations include:

AI-powered monitoring systems.

IoT-enabled safety alerts.

Ultra-light, eco-friendly composite materials.

They will do more than protect—they will communicate, adapt, and evolve.

Guide Rails

Guide rails are more than simple barriers. They are guardians of safety, precision tools in machinery, and silent enablers of progress. Their role in saving lives and improving efficiency makes them a foundation of modern infrastructure and industries. As technology advances, guide rails will only become more reliable, intelligent, and environmentally responsible.

FAQs

What are guide rails used for?

Guide rails are used to control movement, prevent accidents, and ensure safety in roads, industries, and buildings.

Are guide rails the same as guardrails?

No. Guide rails primarily guide and align movement, while guardrails focus on blocking and protecting.

What materials are best for guide rails?

Steel is most common for durability, but aluminum, composites, and plastics are also used based on application.

How long do guide rails last?

With proper maintenance, steel guide rails can last decades, while plastic and composite rails have shorter lifespans.

Why are guide rails important in factories?

They keep products aligned, reduce errors, and improve worker safety on conveyor and assembly systems.

What is the future of guide rails?

Smart guide rails with sensors, eco-friendly materials, and AI integration are expected to dominate the future.

Conclusion

Guide rails are everywhere—on highways, in elevators, in factories, and even in the gadgets we use. They are safety enablers, precision tools, and sustainability challenges rolled into one. Though often overlooked, their impact is profound. Looking ahead, guide rails will continue to evolve, becoming smarter, safer, and greener, protecting lives while pushing industries forward.

Suggestions for Inbound Links

Internal link to an article on road safety equipment

Internal link to a post on automation in industries

Internal link to building safety regulations