Outline for “Linear Motion Bearings”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Motion Bearings | Importance in Modern Engineering |

| What are Linear Motion Bearings? | Concept, Function, Basic Principles |

| History and Evolution of Linear Motion Bearings | From Sliding Bushings to Precision Rolling Bearings |

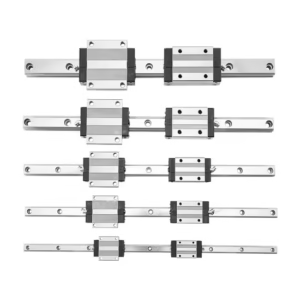

| Key Components of Linear Motion Bearings | Rails, Shafts, Bearing Housings, Rolling Elements |

| How Do Linear Motion Bearings Work? | Motion Mechanism, Load Distribution |

| Different Types of Linear Motion Bearings | Ball Bearings, Roller Bearings, Plain Bearings |

| Ball Type Linear Motion Bearings | Advantages, Common Uses |

| Roller Type Linear Motion Bearings | High Load Applications, Rigidity |

| Plain Linear Motion Bearings | Simplicity, Low-Maintenance Applications |

| Advantages of Linear Motion Bearings | Precision, Durability, Energy Efficiency |

| Applications of Linear Motion Bearings | Robotics, CNC Machines, Medical Devices, Automotive |

| Linear Motion Bearings in Robotics | High-Speed Precision, Vibration-Free Movement |

| Linear Motion Bearings in CNC Machines | Milling, Engraving, Cutting |

| Linear Motion Bearings in Medical Equipment | Imaging Machines, Surgical Robots |

| How to Select the Right Linear Motion Bearing | Load, Speed, Accuracy, Environment |

| Factors Influencing Bearing Performance | Lubrication, Alignment, Material Choice |

| Installation of Linear Motion Bearings | Tools, Step-by-Step Setup |

| Maintenance of Linear Motion Bearings | Cleaning, Lubrication, Wear Inspection |

| Common Problems and Troubleshooting | Noise, Misalignment, Premature Wear |

| Future Trends in Linear Motion Bearings | Smart Bearings, IoT, Predictive Maintenance |

| Top Manufacturers of Linear Motion Bearings | THK, NSK, HIWIN, SKF |

| Cost Analysis of Linear Motion Bearings | Pricing, Long-Term Investment Value |

| Linear Motion Bearings vs. Traditional Bushings | Efficiency, Accuracy, Durability |

| Linear Motion Bearings | Recap of Importance and Future Growth |

| FAQs | Six Most Common Questions |

| Conclusion | Final Insights |

Introduction to Linear Motion Bearings

Linear motion bearings are at the core of precision machinery. They allow equipment to move smoothly in a straight line with minimal friction, enabling industries like robotics, CNC machining, and healthcare to function at peak efficiency. Without these bearings, modern automation would struggle with accuracy, energy loss, and premature wear.

What are Linear Motion Bearings?

Linear motion bearings are specialized mechanical components designed to facilitate smooth, low-friction motion along a linear path. Unlike rotary bearings, which support circular motion, linear motion bearings focus exclusively on straight-line movement. They consist of a shaft or rail and a housing containing rolling or sliding elements that support the load.

History and Evolution of Linear Motion Bearings

The earliest linear guides relied on sliding bushings made of bronze or wood. These were effective but caused wear and high energy consumption. The 20th century brought rolling element technology, revolutionizing linear systems with ball and roller bearings. Today, advanced coatings, heat treatments, and precision machining have made linear bearings more durable, accurate, and maintenance-friendly than ever before.

Key Components of Linear Motion Bearings

Shaft or Rail – Provides the path for movement.

Bearing Housing – Encases and supports rolling elements.

Rolling Elements – Balls or rollers that reduce friction.

Seals and Retainers – Protect against dust and extend service life.

How Do Linear Motion Bearings Work?

Linear bearings work on the principle of rolling contact. As the carriage or housing moves, the rolling elements reduce friction by rolling rather than sliding. This ensures smoother, faster motion with less energy consumption and greater load-handling ability compared to plain sliding systems.

Different Types of Linear Motion Bearings

Ball Linear Motion Bearings – For smooth, high-speed, precise movement.

Roller Linear Motion Bearings – For heavier loads with greater rigidity.

Plain Linear Motion Bearings – For quiet, maintenance-free operation.

Ball Type Linear Motion Bearings

Ball bearings are the most common type. They use recirculating balls between the shaft and housing. Known for their accuracy and low friction, they are widely used in robotics, CNC machines, and laboratory equipment.

Roller Type Linear Motion Bearings

Roller bearings replace balls with cylindrical rollers, giving them greater contact area. This makes them more rigid and able to handle heavier loads. They are ideal for injection molding machines, presses, and heavy-duty automation systems.

Plain Linear Motion Bearings

Plain bearings do not use rolling elements. Instead, they rely on low-friction materials like PTFE or bronze. They are often quieter, require little to no lubrication, and are suitable for low-speed applications.

Advantages of Linear Motion Bearings

High Precision – Ensures accuracy in repeated motion.

Durability – Withstands continuous use with minimal wear.

Energy Efficiency – Reduces power consumption.

High Load Capacity – Especially with roller designs.

Low Maintenance – With proper lubrication and seals.

Applications of Linear Motion Bearings

Linear motion bearings are essential in:

Robotics – Smooth, vibration-free automation.

CNC Machines – Precision milling, cutting, and engraving.

Medical Equipment – Imaging machines and surgical robots.

Automotive Industry – Testing equipment and assembly automation.

Linear Motion Bearings in Robotics

In robotics, precision and stability are crucial. Linear motion bearings allow arms and axes to move smoothly without vibration, ensuring accurate, repeatable performance in assembly lines and automated systems.

Linear Motion Bearings in CNC Machines

CNC machines depend heavily on linear bearings for accuracy. Bearings guide cutting tools along precise paths, which ensures clean cuts, minimal tolerance errors, and high-quality production.

Linear Motion Bearings in Medical Equipment

In MRI scanners, CT machines, and robotic surgery tools, linear bearings provide smooth, controlled motion. Precision in these systems ensures patient safety and reliable performance.

How to Select the Right Linear Motion Bearing

Factors to consider:

Load capacity – Will the bearing support the required weight?

Speed – High-speed applications need ball bearings.

Environment – Dust, moisture, or chemicals require protective seals.

Precision – Micrometer-level accuracy may be needed in CNC or medical devices.

Factors Influencing Bearing Performance

Lubrication quality and frequency

Alignment accuracy during installation

Choice of materials (stainless steel, ceramic, coated alloys)

Environmental exposure to dust or moisture

Installation of Linear Motion Bearings

Steps include:

Cleaning and preparing the shaft or rail.

Aligning housing and rails accurately.

Mounting with controlled torque to avoid misalignment.

Testing for smooth, vibration-free movement.

Maintenance of Linear Motion Bearings

Apply lubrication regularly (oil or grease).

Clean dust and debris to prevent premature wear.

Inspect seals, housing, and rolling elements.

Replace worn-out components early to avoid failure.

Common Problems and Troubleshooting

Noise or rough motion – Usually indicates poor lubrication.

Misalignment – Leads to uneven wear and reduced precision.

Premature failure – Caused by contamination or overload.

Future Trends in Linear Motion Bearings

Smart Bearings – Equipped with sensors for monitoring load, wear, and lubrication.

IoT Integration – Predictive maintenance through data collection.

Advanced Materials – Coatings and ceramics for longer life.

Compact Designs – For lightweight automation and robotics.

Top Manufacturers of Linear Motion Bearings

THK (Japan)

NSK (Japan)

HIWIN (Taiwan)

SKF (Sweden)

These companies dominate the global market with innovative and reliable solutions.

Cost Analysis of Linear Motion Bearings

Prices vary widely:

Basic models – Around $30–$50.

Industrial precision bearings – $500–$3,000 depending on size and capacity.

Investing in higher-quality bearings reduces downtime and maintenance costs in the long term.

Linear Motion Bearings vs. Traditional Bushings

| Feature | Linear Motion Bearings | Traditional Bushings |

|---|---|---|

| Friction | Very low | High |

| Precision | Excellent | Moderate |

| Load Handling | High (roller types) | Limited |

| Maintenance | Requires lubrication | Often lower |

| Cost | Higher upfront | Lower initial cost |

Linear Motion Bearings

Linear motion bearings are vital components for precision and efficiency in modern industries. They offer smooth, reliable, and long-lasting motion that supports automation, robotics, and medical equipment. As industries evolve, linear motion bearings will continue to improve with smart technologies, ensuring they remain indispensable.

FAQs

What is the function of linear motion bearings?

They provide smooth, friction-free, and accurate linear movement.

Do linear motion bearings require lubrication?

Yes, proper lubrication extends life and reduces wear.

Which industries use linear motion bearings most?

Robotics, CNC machining, medical, and automotive industries.

What is the difference between ball and roller linear motion bearings?

Ball bearings are smoother and faster, while roller bearings are stronger and handle heavier loads.

How long do linear motion bearings last?

With proper maintenance, they can last for years even under continuous use.

Are linear motion bearings expensive?

They vary in cost but offer excellent long-term value by reducing downtime.

Conclusion

Linear motion bearings are the foundation of precision in modern machines. Their ability to provide frictionless, accurate, and repeatable motion makes them indispensable across industries. With the rise of IoT and smart automation, the future of linear motion bearings looks promising, ensuring even greater efficiency, durability, and intelligence in industrial applications.

Suggested Inbound Links:

Guide on CNC machining technologies

Blog on robotics in industrial automation

Article about industrial lubrication best practices