Outline for Linear Slides Article

| Main Topic | Subtopics |

|---|---|

| Introduction to Linear Slides | Definition, History, Importance in engineering |

| What are Linear Slides? | Basic explanation, Motion control role |

| How Linear Slides Work | Mechanism, Load support, Smooth motion |

| Types of Linear Slides | Ball bearing, Roller bearing, Dovetail, Air bearing, Crossed roller |

| Linear Slides vs. Linear Rails | Key differences, Use cases, Similarities |

| Materials Used in Linear Slides | Steel, Aluminum, Composites, Polymers |

| Design Considerations for Linear Slides | Load capacity, Accuracy, Speed, Environment |

| Applications in Automation | Robotics, CNC machines, 3D printers |

| Industrial Applications of Linear Slides | Packaging, Assembly lines, Heavy machinery |

| Medical and Scientific Applications | Imaging systems, Lab equipment, Surgical robotics |

| Linear Slides in Transportation | Automotive, Aerospace, Rail systems |

| Precision and Accuracy in Linear Slides | Tolerances, Repeatability, Wear resistance |

| Advantages of Linear Slides | High precision, Durability, Smooth motion |

| Disadvantages of Linear Slides | Cost, Maintenance, Contamination risks |

| Installation of Linear Slides | Alignment, Mounting, Safety checks |

| Maintenance of Linear Slides | Lubrication, Cleaning, Inspection, Replacement |

| Cost Factors of Linear Slides | Material, Technology, Application |

| Innovations in Linear Slides | Smart sensors, Self-lubrication, Eco-friendly options |

| Linear Slides in Architecture | Elevators, Sliding doors, Automated systems |

| Safety Standards for Linear Slides | ISO standards, Industry regulations |

| Case Studies Using Linear Slides | Robotics, Aerospace, Medical equipment |

| Future of Linear Slides | AI integration, Nanotechnology, Sustainability |

| Linear Slides | Complete overview and importance |

| FAQs | At least 6 questions with answers |

| Conclusion | Final thoughts and future relevance |

Introduction to Linear Slides

From factory floors to robotic labs, linear slides are the unsung heroes that keep machines moving with precision and control. Whenever a part needs to move in a straight line smoothly, reliably, and with repeatable accuracy, linear slides step in.

These systems have revolutionized industries, enabling robots, CNC machines, and even surgical tools to perform tasks that demand micrometer-level precision. As technology advances, linear slides have evolved from simple mechanical designs to sophisticated, sensor-enabled components.

This article explores everything about linear slides—their types, applications, benefits, and future.

What are Linear Slides?

A linear slide is a motion system designed to provide controlled, straight-line movement. It combines rails and bearings into one system, allowing objects to slide along a single axis with minimal friction.

Key roles of linear slides include:

- Supporting loads while maintaining straight motion.

- Reducing friction for smooth operation.

- Ensuring repeatable accuracy in automation and robotics.

They are fundamental in industries where precision and efficiency define success.

How Linear Slides Work

The mechanism behind linear slides is simple yet effective:

- A moving carriage or platform glides along fixed rails.

- Bearings (ball, roller, or air) reduce friction.

- Forces are evenly distributed to maintain accuracy.

This setup ensures smooth and stable motion, even under heavy loads or high speeds.

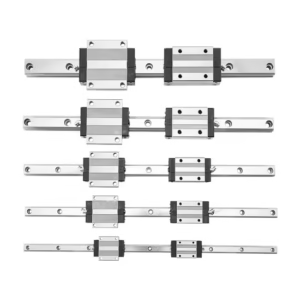

Types of Linear Slides

Linear slides vary widely, each suited to specific tasks:

- Ball bearing slides: Popular for precision machinery; use ball bearings for low friction.

- Roller bearing slides: Handle heavier loads with cylindrical rollers.

- Dovetail slides: Strong and durable, ideal for heavy-duty applications.

- Air bearing slides: Use a thin film of air for virtually frictionless motion.

- Crossed roller slides: Offer ultra-high precision with roller elements crossing at 90°.

Selecting the right type depends on performance needs and environment.

Linear Slides vs. Linear Rails

Although often confused, they differ:

- Linear slides: Combine rail and carriage as a unit for motion.

- Linear rails: Are guiding tracks that need separate bearings.

In short, slides are integrated systems, while rails are modular components.

Materials Used in Linear Slides

Material choice defines durability and performance:

- Steel: Strong and wear-resistant.

- Aluminum: Lightweight and corrosion-resistant.

- Polymers: Self-lubricating and low-cost.

- Composites: Eco-friendly, flexible, and advanced.

Engineers match materials to the environment (e.g., cleanrooms, heavy industries).

Design Considerations for Linear Slides

When designing or selecting linear slides, engineers evaluate:

- Load capacity (static and dynamic).

- Accuracy and repeatability.

- Speed and acceleration.

- Environmental factors (dust, heat, vibration).

Poor design choices can cause inefficiency, downtime, or failure.

Applications in Automation

Automation thrives on linear slides:

- Robotics: Enable precise arm movements.

- CNC machines: Guide cutting tools with high accuracy.

- 3D printers: Ensure smooth layer alignment.

Without slides, modern automation would not exist.

Industrial Applications of Linear Slides

Factories and heavy industries rely on them too:

- Packaging lines: Ensure smooth material handling.

- Assembly lines: Maintain precision and speed.

- Heavy machinery: Provide strength and stability under stress.

They boost productivity and reduce downtime.

Medical and Scientific Applications

In healthcare and research, precision is vital:

- Imaging equipment: Enable smooth patient positioning.

- Lab automation: Support accurate pipetting and scanning.

- Surgical robots: Provide ultra-precise motion control.

Here, linear slides are life-saving tools.

Linear Slides in Transportation

Beyond factories, they support transport systems:

- Automotive: Used in testing rigs and assembly lines.

- Aerospace: Assist in component assembly and testing.

- Rail systems: Support sliding mechanisms in doors and controls.

Transportation industries demand reliability—and slides deliver.

Precision and Accuracy in Linear Slides

The hallmark of linear slides is precision:

- Tolerances can reach microns.

- Repeatability ensures consistent performance.

- Wear resistance maintains long-term accuracy.

This makes them ideal for scientific and high-tech applications.

Advantages of Linear Slides

Linear slides offer numerous benefits:

- Smooth, controlled motion.

- High durability and strength.

- Low friction and wear.

- Versatility across industries.

They balance precision with reliability.

Disadvantages of Linear Slides

Yet, challenges exist:

- Costly for high-end models.

- Maintenance needed (lubrication, cleaning).

- Contamination risks in dusty environments.

However, innovations are addressing these drawbacks.

Installation of Linear Slides

Proper setup ensures long life:

- Accurate alignment is crucial.

- Rails must be mounted on stable surfaces.

- Pre-lubrication prevents early wear.

- Safety checks confirm smooth motion.

Poor installation can ruin even the best slide.

Maintenance of Linear Slides

Care extends service life:

- Regular lubrication.

- Routine cleaning.

- Inspection for wear or cracks.

- Timely replacement of components.

Preventive care saves costs in the long run.

Cost Factors of Linear Slides

Costs depend on:

- Material (steel vs. aluminum).

- Precision (micron tolerances cost more).

- Application (medical vs. industrial).

Although expensive, their long-term efficiency offsets the price.

Innovations in Linear Slides

Technology is transforming slides:

- Smart sensors detect wear and alignment.

- Self-lubricating systems reduce maintenance.

- Eco-friendly materials lower environmental impact.

These make slides smarter, cleaner, and more efficient.

Linear Slides in Architecture

In buildings, slides ensure convenience:

- Elevators: Guide cabins smoothly.

- Sliding doors: Enable quiet, stable motion.

- Automated storage: Maximize vertical space.

Architecture relies on them for both function and safety.

Safety Standards for Linear Slides

Compliance ensures reliability:

- ISO standards for precision components.

- DIN regulations in Europe.

- Industry-specific certifications in aerospace and healthcare.

Following standards prevents costly failures.

Case Studies Using Linear Slides

- Robotics in Japan: Linear slides improved assembly efficiency by 30%.

- Medical devices in Germany: Precision slides enhanced MRI machines.

- Aerospace in the US: Slides provided reliable motion in satellite assembly.

These cases prove their global importance.

Future of Linear Slides

The next generation of slides will be:

- AI-powered for predictive maintenance.

- Nano-engineered for ultra-smooth motion.

- Sustainable with recycled and composite materials.

Expect smarter, greener, and more efficient slides in years to come.

Linear Slides

Linear slides are more than motion devices—they’re the backbone of automation, robotics, and precision engineering. Their ability to combine strength, accuracy, and durability makes them indispensable across industries. As technology advances, they will only grow smarter and more sustainable, powering the future of precision machinery.

FAQs

What are linear slides used for?

They provide smooth, precise motion in automation, robotics, and machinery.

What types of linear slides exist?

Ball bearing, roller, dovetail, air bearing, and crossed roller slides.

How do you maintain linear slides?

Regular lubrication, cleaning, and inspection are required.

Are linear slides expensive?

High-precision models can be costly but offer long-term savings.

What industries use linear slides?

Automation, aerospace, medical, packaging, and architecture.

What is the future of linear slides?

AI integration, self-lubrication, and eco-friendly materials will define the future.

Conclusion

Linear slides are silent powerhouses in modern engineering. They enable precision in manufacturing, safety in healthcare, and efficiency in robotics. As industries demand higher accuracy and sustainability, slides will continue to evolve—becoming smarter, stronger, and greener. They’re not just parts of machines; they’re drivers of innovation.

Suggestions for Inbound Links

- Internal link to linear bearings and rails guide

- Internal link to automation in industries

- Internal link to future of robotics

Suggestions for Outbound Links

- ISO Standards for Motion Systems

- European Committee for Standardization

- American Bearing Manufacturers Association