Introduction to Heavy Duty Linear Guides

In the world of industrial automation, precision machinery, and heavy-duty applications, the importance of reliable motion systems cannot be overstated. Heavy-duty linear guides are critical components in a wide range of mechanical systems, providing smooth, precise, and stable linear motion even under the most demanding conditions. These guides, built to support high loads, heavy machinery, and harsh environments, are the backbone of equipment like CNC machines, industrial robots, conveyors, and more.

Heavy-duty linear guides are designed to withstand greater stress, deliver superior performance, and endure constant wear and tear. By reducing friction between moving parts, they help to ensure precise movement and extended service life for complex machinery.

In this article, we will explore the key features, types, applications, and benefits of heavy-duty linear guides, as well as provide tips on how to select and maintain them.

What Are Heavy Duty Linear Guides?

A linear guide (or linear slide) is a mechanical device that provides smooth and precise linear motion along a fixed track. Heavy-duty linear guides are specifically designed to handle larger loads, operate in tougher environments, and deliver high accuracy in applications requiring sustained heavy movement. These guides are typically used in machinery where high payloads, rigidity, and precision are essential, such as industrial automation, material handling, or large machine tools.

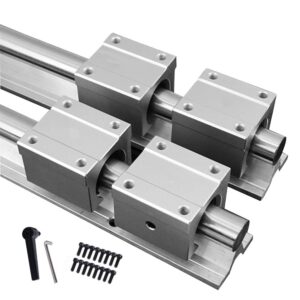

A heavy-duty linear guide assembly generally consists of:

Rails: The stationary part of the guide system.

Carriages/Blocks: The moving component that travels along the rail, supporting the load.

Rolling Elements: Typically ball bearings or roller bearings, which reduce friction between the rail and the carriage, allowing smooth motion.

The robustness of heavy-duty linear guides comes from their ability to handle substantial axial, radial, and moment loads while maintaining precision, even under high speeds or harsh conditions.

Key Features of Heavy Duty Linear Guides

Load Capacity:

One of the defining characteristics of heavy-duty linear guides is their ability to handle high loads. These systems are built to carry substantial weights, making them ideal for industrial applications where machines need to support large workpieces, tooling, or heavy motors.Precision and Accuracy:

Despite their strength, heavy-duty linear guides provide excellent precision. The rolling elements (balls or rollers) and the tight tolerances of the rails ensure that motion is smooth and accurate, with minimal deflection and backlash. This precision is essential in applications such as CNC machining, robotic arms, and assembly lines.Durability:

Heavy-duty linear guides are built to last. They are designed with rugged materials and superior sealing systems to protect against contaminants such as dust, dirt, moisture, and chemicals. Their robust construction ensures that they perform reliably in harsh or high-demand environments.Load Distribution:

The ability to distribute loads evenly across multiple points of contact in the system reduces stress on individual components. This is particularly important for preventing premature wear or failure in high-load applications.Self-Lubricating or Low Maintenance:

Many heavy-duty linear guides feature advanced lubricating systems, such as sealed bearings or self-lubricating materials, reducing the need for regular maintenance and enhancing performance over the long term.Resistance to Harsh Environments:

These systems are engineered to resist corrosion, high temperatures, and other challenging environmental conditions, making them suitable for industries like aerospace, automotive, manufacturing, and more.

Types of Heavy Duty Linear Guides

Heavy-duty linear guides come in various designs and configurations to meet specific application requirements. Here are the most common types:

Ball Bearing Linear Guides

Ball bearing linear guides use spherical balls between the rail and carriage to reduce friction and ensure smooth motion. These guides offer high load capacity, low friction, and the ability to operate at high speeds. They are widely used in CNC machines, pick-and-place robots, and automated material handling.Roller Bearing Linear Guides

Roller bearings use cylindrical rollers instead of balls. They are more suitable for applications requiring even higher load capacities, as the larger contact area of the rollers distributes the load more evenly. Roller-bearing guides are ideal for large industrial machines, heavy equipment, and other systems with significant weight-bearing requirements.Cross Roller Guides

Cross roller guides consist of rollers arranged perpendicular to one another, allowing them to handle both radial and axial loads. This configuration provides high rigidity and is particularly useful in machines where both types of forces act simultaneously, such as in high-precision applications like robotics and high-speed machining.Profile Rail Guides

Profile rail guides are designed with higher stiffness and load-bearing capacity. The rails typically have a rectangular or square cross-section and are often made of hardened steel for added durability. Profile rail guides can support heavier loads and are ideal for large machines and equipment used in the automotive or aerospace industries.Heavy Duty Linear Modules

A linear module is a pre-assembled unit that combines the linear guide and motor into a single integrated system. Heavy-duty linear modules are ideal for applications that require high-load carrying capacities, such as automated storage systems, machine tool positioning, and large conveyor systems. These modules can be configured for both horizontal and vertical movement.

Applications of Heavy Duty Linear Guides

Heavy-duty linear guides are used in a wide range of industries and applications. Some of the most common include:

CNC Machines

CNC machines require precise and smooth linear motion to ensure accurate cutting, milling, or grinding operations. Heavy-duty linear guides provide the necessary stability and load capacity to handle the high forces involved in these operations.Robotics and Automation

Robots, particularly industrial robots, rely on heavy-duty linear guides to move arms and tools with precision and repeatability. These guides help maintain the accuracy of movements in complex assembly or material handling tasks.Material Handling Systems

In automated warehouses and production lines, linear guides help move heavy pallets, parts, and products smoothly along conveyor belts, robotic arms, or custom transport systems.Industrial Machinery

In industries such as automotive, aerospace, and construction, heavy-duty linear guides are used in machine tools, presses, and other large equipment to facilitate high-precision movements under heavy load conditions.Medical Equipment

Some medical devices, such as imaging systems, dialysis machines, and robotics-assisted surgery systems, require linear motion components that can handle high loads while maintaining precise movement. Heavy-duty linear guides are essential in these applications.Injection Molding Machines

Heavy-duty linear guides are used in injection molding machines to ensure precise movement of molds under heavy stress, ensuring high-quality production of plastic parts.Aerospace and Defense

In the aerospace and defense industries, linear guides are used in large structures, such as satellites, aircraft, and missile systems, where high load capacities and accurate motion are critical for performance and safety.

Advantages of Heavy Duty Linear Guides

Improved Precision

Heavy-duty linear guides ensure that machinery operates with a high level of precision. This is essential for manufacturing processes that require tight tolerances and repeatability.Higher Load Capacity

These systems are designed to handle large loads, which helps prevent deformation, instability, and premature wear in industrial machinery and robotic systems.Increased Durability

The rugged design and protective features of heavy-duty linear guides extend their service life, reducing downtime, increasing productivity, and lowering maintenance costs.Reduced Friction and Wear

The rolling elements (ball or roller bearings) help reduce friction, which in turn lowers energy consumption, reduces heat buildup, and minimizes wear on moving parts.Minimal Maintenance Requirements

With advanced sealing systems, lubrication options, and durable materials, heavy-duty linear guides often require less maintenance, which translates into lower long-term operating costs.

How to Select the Right Heavy Duty Linear Guide

Choosing the right heavy-duty linear guide for your application involves considering several factors:

Load Requirements:

Consider both the dynamic load (the load the guide will carry while in motion) and the static load (the load when the guide is stationary). Heavy-duty guides come in different load capacities, so selecting the appropriate one for your system is crucial.Speed and Accuracy:

Determine the required speed of movement and the level of accuracy needed in your application. Ball bearing guides are best for high-speed, precise motion, while roller bearings excel in high-load, slower-moving applications.Environmental Conditions:

Consider factors such as dust, moisture, temperature extremes, or chemicals that may affect the performance of the guide. If your application is in a harsh environment, look for guides with high-quality seals and corrosion-resistant materials.Installation Space:

Ensure that the linear guide system fits within the constraints of your machine’s design. Compact and profile rail guides are ideal when space is limited.Mounting and Alignment:

Make sure that the linear guide system is easy to install and align. Misalignment can cause uneven wear and reduce the lifespan of the guide.

Maintenance of Heavy Duty Linear Guides

Although heavy-duty linear guides are built for durability, proper maintenance ensures they continue to perform optimally. Here are some basic maintenance tips:

Regular Cleaning:

Periodically clean the rails and carriages to remove debris and dirt. Contaminants can affect the performance and lifespan of the guide.Lubrication:

Make sure the guide is adequately lubricated. Some guides are self-lubricating, while others may require periodic lubrication with grease or oil.Check Seals:

Seals play a crucial role in preventing contaminants from entering the guide system. Regularly check that the seals are intact to prevent water, dust, and chemicals from getting inside.Check Load and Alignment:

Ensure that the guide is aligned properly during operation. Misalignment can lead to uneven wear and affect the precision of the system. Regularly inspect the load distribution and alignment.Inspect Bearings for Wear:

Bearings are a vital part of the guide system. Check for wear, damage, or unusual sounds during operation to ensure they are not generating excess friction, which could cause overheating or premature failure.

Conclusion

Heavy-duty linear guides are essential components in high-load, high-precision applications across industries. Whether in CNC machines, robotic arms, material handling systems, or high-demand manufacturing processes, these guides provide the necessary stability, durability, and accuracy required to keep machinery running smoothly.

Their robust design allows them to endure extreme conditions while maintaining precision over extended use, making them invaluable in modern industrial operations. By understanding the different types, advantages, and maintenance needs of heavy-duty linear guides, businesses can enhance productivity, reduce downtime, and improve long-term operational efficiency.

When selecting a heavy-duty linear guide, factors like load capacity, speed, precision, and environment must be carefully considered to ensure the right fit. With proper maintenance, these systems can provide years of reliable service, making them indispensable in industrial and automated systems.

Related Links