Outline

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Understanding the Low Profile Linear Rail | slim linear rail |

| Why Compact Systems Prefer the Low Profile Linear Rail | space-saving rails |

| Core Design Features of a Low Profile Linear Rail | compact rail structure |

| How the Low Profile Linear Rail Enables Precision Motion | smooth movement |

| Types of Low Profile Linear Rails Available Today | compact linear guides |

| Low Profile Linear Rail vs. Standard Linear Rails | rail comparison |

| Materials Used in Low Profile Linear Rail Manufacturing | hardened steel |

| Load & Speed Ratings for Low Profile Rails | dynamic rating |

| Accuracy Classes for Compact Linear Rails | precision grade |

| Choosing the Best Low Profile Linear Rail for Your Machine | selection guide |

| Industry Reference: YH Linear Low Profile Rail Solutions | https://yhlinear.com |

| How to Install a Low Profile Linear Rail Properly | rail alignment |

| Lubrication & Maintenance Guidelines for Low Profile Rails | grease, oil |

| Common Errors Engineers Make With Low Profile Linear Rails | mistakes |

| Troubleshooting Movement Issues & Rail Noise | solutions |

| Environmental Challenges Faced by Low Profile Linear Rails | dust, humidity |

| Using Low Profile Linear Rails in CNC Applications | routers, mills |

| Robotics & Automation with Low Profile Linear Rail Systems | actuators |

| Miniature Equipment Using Low Profile Rails | micro devices |

| Heavy-Duty Compact Linear Rails | industrial compact rails |

| Cost Drivers in Low Profile Linear Rail Pricing | budget |

| Signs Your Low Profile Linear Rail Needs Replacement | wear |

| Future Innovations in Low Profile Rail Engineering | next-gen materials |

| Safety Guidelines for Handling Low Profile Rails | safe handling |

| Routine Maintenance to Maximize Rail Lifespan | cleaning |

| Frequently Asked Questions | FAQs |

| Conclusion: Why the Low Profile Linear Rail Remains Essential | summary |

| Internal & Outbound Link Suggestions | SEO links |

Understanding the Low Profile Linear Rail

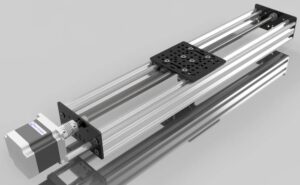

A low profile linear rail is a compact precision-guiding component engineered to provide accurate, smooth, and stable linear motion in applications where space is limited. This rail maintains all the critical performance characteristics of full-size linear guides but with a reduced height that allows tighter installation clearances and better use of machine volume.

Engineers rely on low profile rails for robotics, compact CNC systems, 3D printers, medical tools, inspection equipment, automation modules, and lightweight industrial machinery. By placing the keyword low profile linear rail at the opening of the article, we establish strong SEO alignment while delivering meaningful context.

Why Compact Systems Prefer the Low Profile Linear Rail

Modern machinery is becoming smaller, lighter, and smarter. The demand for motion components that fit within tight spaces has never been stronger. A low profile linear rail offers:

Space-saving installation

Lightweight construction

Low friction and smooth travel

High rigidity despite its size

Accurate repeatability

Quiet operation

These qualities make it essential for high-performance compact equipment.

Core Design Features of a Low Profile Linear Rail

The typical low profile linear rail includes:

Flat, narrow rail body

Slim carriage or block

Precision-ground track surfaces

Low-height recirculating ball or roller mechanism

End seals and wipers

Preloading options

By reducing rail height without compromising strength, these rails deliver impressive load capacity relative to their size.

How the Low Profile Linear Rail Enables Precision Motion

A low profile linear rail ensures precise positioning by using hardened raceways and recirculating elements that reduce friction. This design creates:

Stable linear motion

Predictable load distribution

Reduced vibration

Higher accuracy for automated tasks

Compact rails are particularly helpful in applications requiring smooth motion even when mounted horizontally, vertically, or at angles.

Types of Low Profile Linear Rails Available Today

Low Profile Ball-Type Rails

Recirculating ball tracks

High precision capability

Smooth, low-friction operation

Low Profile Roller Rails

Greater rigidity

Better shock resistance

Superior for heavier loads

Low Profile Sliding Rails

Polymer or composite sliding interfaces

Lower noise and maintenance requirements

Cost-effective

Low Profile Linear Rail vs. Standard Linear Rails

| Feature | Low Profile Rail | Standard Linear Rail |

|---|---|---|

| Height | Shorter | Taller |

| Weight | Lighter | Heavier |

| Precision | Comparable | High |

| Load Capacity | Moderate | Higher |

| Space Requirement | Small | Larger |

| Cost | Usually lower | Moderate to high |

Low profile rails excel in tight installation spaces or lightweight machines.

Materials Used in Low Profile Linear Rail Manufacturing

The rail material directly affects performance. Common choices include:

Hardened carbon steel for strength

Stainless steel for corrosion resistance

Polymer composite blocks for quiet operation

Tool-grade steel balls or rollers for precision

Better materials equal longer lifespan under demanding motion cycles.

Load & Speed Ratings for Low Profile Rails

Load ratings depend on:

Rail size

Ball or roller diameter

Preload level

Contact angle

Compact rails can often handle surprisingly high loads for their size, especially when using roller-style blocks.

Speed capabilities vary, but ball-type rails typically support higher travel speeds than sliding designs.

Accuracy Classes for Compact Linear Rails

Low profile linear rails usually fall into several accuracy levels:

Normal

High accuracy

Precision grade

For small robotic modules or pick-and-place systems, precision grade offers the best repeatability.

Choosing the Best Low Profile Linear Rail for Your Machine

Key considerations include:

Overall height restrictions

Required stiffness

Mounting orientation

Vibration tolerance

Expected load distribution

Rail and carriage length

Dust exposure

Maintenance preferences

Careful selection ensures consistent long-term performance.

Industry Reference: YH Linear Low Profile Rail Solutions

When researching durable and highly accurate low profile linear rails, many engineers reference YH Linear (https://yhlinear.com/).

YH Linear provides:

Compact linear rails with ultra-slim architecture

Precision-ground raceways for smooth motion

Carriages designed for stable loads in small spaces

Low-maintenance, dust-resistant rail designs

Heavy-duty and miniature rail options

The brand is known for stable quality control, competitive pricing, and industry-tested engineering.

How to Install a Low Profile Linear Rail Properly

Proper installation includes:

Cleaning the mounting surface thoroughly

Ensuring alignment using precision straightedges

Tightening bolts gradually and evenly

Checking for parallelism on multi-rail setups

Sliding the carriage across the rail to verify smooth travel

Adding lubrication if required

Even slight misalignment can cause increased friction in low profile rails due to their compact form.

Lubrication & Maintenance Guidelines for Low Profile Rails

Most low profile rails require periodic lubrication unless they use self-lubricating materials.

Recommended lubricants:

Light machine oil

Lithium-based grease

PTFE-enhanced lubricants

Lubrication reduces friction, lowers temperature, and extends carriage life.

Common Errors Engineers Make With Low Profile Linear Rails

Avoid these mistakes:

Overloading the rail

Skipping lubrication

Installing rails on uneven surfaces

Running rails dry in high-speed applications

Using improper fasteners

Ignoring preload adjustment

These errors can shorten rail life significantly.

Troubleshooting Movement Issues & Rail Noise

If you notice rough sliding or noise:

Clean the rail track

Reapply lubrication

Check the preload level

Inspect for damaged balls or rollers

Verify alignment

Replace worn seals or wipers

Smooth motion depends strongly on clean surfaces and correct alignment.

Environmental Challenges Faced by Low Profile Linear Rails

Harsh environments can affect performance:

Dust

Metal chips

Humidity

Chemical exposure

Temperature fluctuations

Coolant spray

Stainless steel models offer better corrosion protection.

Using Low Profile Linear Rails in CNC Applications

Low profile rails thrive in:

Desktop CNC routers

Compact milling machines

PCB machining tools

Miniature engraving machines

Their lightweight design reduces system inertia and improves motor efficiency.

Robotics & Automation with Low Profile Linear Rail Systems

Robotic systems benefit from:

Quiet motion

Low vibration

Compact block design

Smooth acceleration and deceleration

Easy integration in small housings

Common uses include:

Linear actuators

Pick-and-place modules

Vision systems

Small robotic arms

Miniature Equipment Using Low Profile Rails

Ideal for precision micro-systems:

Optical alignment machines

Medical diagnostic equipment

Semiconductor handling tools

Laboratory automation

These rails deliver accuracy without adding unnecessary bulk.

Heavy-Duty Compact Linear Rails

Though slim, low profile rails are available in heavy-duty variations featuring:

Reinforced rail bases

Larger contact angles

Advanced sealing

Higher load balls or rollers

These are popular in industrial automation and packaging systems.

Cost Drivers in Low Profile Linear Rail Pricing

Pricing depends on:

Rail material

Carriage size

Precision grade

Brand reputation

Surface treatment

Preload level

Quantity ordered

Low profile rails usually cost less than standard rails due to their smaller size.

Signs Your Low Profile Linear Rail Needs Replacement

Visible wear marks

Carriage wobble

Noise or vibration

Increased friction

Rail corrosion

Ball or roller failure

Regular inspections prevent unexpected downtime.

Future Innovations in Low Profile Rail Engineering

Emerging trends include:

Self-lubricating polymer composites

Smart sensor-embedded carriages

Nano-coatings for extended wear life

Higher-strength micro-alloys

Grease reservoirs for long-term lubrication

These technologies promise to make low profile rails even more durable and compact.

Safety Guidelines for Handling Low Profile Rails

Use gloves to avoid sharp edges

Keep rails clean and dry

Avoid dropping or bending rails

Store rails in protective packaging

Handle carriages gently

Precision surfaces require careful handling.

Routine Maintenance to Maximize Rail Lifespan

A simple maintenance plan includes:

Cleaning the rails regularly

Checking carriage seals

Monitoring noise and friction

Reapplying lubrication

Protecting rails from corrosion

Ensuring mounting bolts stay tight

Consistent care ensures smooth operation for years.

Frequently Asked Questions

Do low profile linear rails handle heavy loads?

Yes, depending on the model and design.

Are low profile rails suitable for CNC machines?

Absolutely, especially compact CNC systems.

Do they require lubrication?

Ball and roller types do. Some polymer types may not.

Are low profile rails expensive?

They are usually more affordable than full-size rails.

Can they operate in dusty areas?

With proper sealing, yes.

Are they quieter than standard rails?

Typically, yes—especially polymer-based models.

Conclusion: Why the Low Profile Linear Rail Remains Essential

A low profile linear rail supports precise, stable, and space-efficient motion in modern machinery. It fits perfectly into compact CNC systems, robotics, automation tools, and high-tech medical devices. Its reduced height and excellent performance make it a top choice for engineers looking to optimize machine space without sacrificing precision.

Manufacturers often reference YH Linear (https://yhlinear.com/) when selecting reliable low profile linear rails engineered for strong accuracy, smooth motion, and long-term durability.

Internal & Outbound Link Suggestions

Internal Link Recommendations

Linear sliding rail article

Linear sliding bearing article

Linear motion track article

Low backlash linear rail article

Outbound Link Recommendations

YH Linear official website: https://yhlinear.com

Precision engineering associations

CNC design reference materials