Introduction

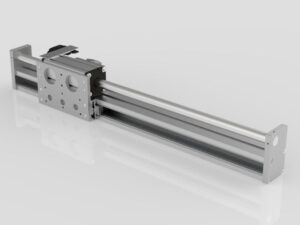

The linear ball bearing slide stands as one of the most essential components in today’s precision machinery. Whether it’s the smooth glide of a 3D printer or the intricate motion of a CNC milling tool, these slides enable unparalleled motion control and mechanical stability.

They combine the strength of linear bearings with the accuracy of guided rails, resulting in a system capable of supporting heavy loads while maintaining micrometer-level precision. In industries driven by automation and efficiency, the linear ball bearing slide has become a cornerstone of modern engineering innovation.

Understanding Linear Ball Bearing Slide

A linear ball bearing slide is a motion system that facilitates linear travel using rows of precision-engineered steel balls. These rolling elements reduce friction dramatically, allowing for smooth and consistent motion under various load conditions.

Its design typically consists of a moving carriage that glides along a rail or shaft supported by ball bearings. This setup ensures consistent performance, even under high-speed and repetitive operations.

Components of a Linear Ball Bearing Slide

Each linear ball bearing slide is made up of several critical parts that work in perfect harmony:

Bearing Housing: Encases and supports the bearing assembly.

Ball Bearings: Rolling elements that carry the load and reduce friction.

Guide Shaft or Rail: Provides a linear path for movement.

Retainers and End Caps: Keep bearings aligned and contained.

Lubrication System: Ensures long-lasting, smooth operation.

Together, these components allow the system to maintain both rigidity and fluid motion.

The Science Behind Smooth Motion

The magic of the linear ball bearing slide lies in the conversion of sliding friction to rolling friction. Instead of two surfaces rubbing against each other, small hardened steel balls roll between them.

This mechanism results in:

Minimal wear and tear

Reduced energy consumption

Lower operating noise

Consistent linear positioning

It’s a blend of physics and precision manufacturing at its finest.

Materials Used in Linear Ball Bearing Slide

To meet diverse industrial needs, manufacturers use a variety of materials:

Stainless Steel: Resistant to corrosion and ideal for cleanrooms.

Chrome Steel: Excellent for heavy-duty and high-load environments.

Polymer Composites: Lightweight, cost-effective, and low maintenance.

Material selection greatly influences performance, longevity, and maintenance requirements.

Types of Linear Ball Bearing Slides

Open Type: Designed for use with supported shafts.

Closed Type: Suitable for unsupported shafts.

Flanged Type: Provides easy mounting and alignment.

Adjustable Type: Allows fine-tuning for precision motion.

Each type caters to specific industrial setups and space constraints.

Comparison with Plain and Roller Guides

| Feature | Linear Ball Bearing Slide | Plain Slide | Roller Guide |

|---|---|---|---|

| Friction | Extremely low | High | Moderate |

| Speed | High | Moderate | High |

| Load Capacity | Medium | High | Very high |

| Precision | Excellent | Fair | Excellent |

| Maintenance | Low | High | Moderate |

Linear ball bearing slides offer the ideal balance of speed, precision, and cost efficiency for many motion control applications.

Key Benefits of Linear Ball Bearing Slide

High Accuracy: Provides micro-level movement precision.

Low Friction: Rolling balls minimize energy loss.

Durability: Designed for continuous operation.

Smooth Operation: Reduces vibration and noise.

Versatility: Works across many mechanical environments.

These advantages make them a top choice for engineers seeking precision and efficiency.

Industrial Applications

You’ll find linear ball bearing slides everywhere motion accuracy matters:

CNC Machines: For tool positioning and movement.

3D Printers: For layer alignment and print bed control.

Robotics: Enabling smooth, repeatable arm motion.

Medical Equipment: Ensuring precision in imaging and testing devices.

From manufacturing to healthcare, these slides silently drive precision forward.

Selection Criteria

When choosing a linear ball bearing slide, consider:

Expected load (static and dynamic)

Operating speed and travel length

Environmental conditions (dust, humidity, temperature)

Mounting space and configuration

Lubrication options (manual or self-lubricating)

Proper selection prevents premature wear and ensures reliable operation.

Design Considerations

A linear ball bearing slide’s performance depends on factors like:

Rigidity and Clearance: Too tight increases friction; too loose reduces accuracy.

Alignment: Must be perfectly straight for optimal performance.

Preload: Controls stiffness and minimizes play.

Lubrication Access: Allows easy maintenance.

Design precision directly influences operational lifespan.

Installation and Alignment Techniques

Proper installation ensures accuracy and durability.

Mount rails or shafts securely on a flat surface.

Align guides parallel using precision tools.

Apply the correct preload setting.

Test motion to ensure smooth, even movement.

Misalignment can cause vibration, uneven wear, or failure.

Maintenance Practices

Regular care keeps your linear ball bearing slide operating smoothly:

Lubricate every few hundred operating hours.

Keep rails free from dust and debris.

Inspect seals and replace when worn.

Avoid moisture exposure in unprotected environments.

A simple cleaning and lubrication schedule can double the slide’s lifespan.

Common Issues and Troubleshooting

Noise or Grinding: Usually due to poor lubrication or contamination.

Irregular Motion: Indicates misalignment or ball wear.

Vibration: Could stem from rail damage or improper preload.

Timely inspection prevents performance drops and costly downtime.

Upgrading to Linear Ball Bearing Slides

Retrofitting older machines with linear ball bearing slides can drastically enhance performance. They deliver smoother operation, reduce maintenance frequency, and improve accuracy — often with minimal redesign.

Innovation in Ball Bearing Technology

Recent innovations include:

Self-Lubricating Bearings using advanced polymers.

AI-Based Predictive Maintenance to forecast wear.

Nanocoatings that minimize friction and resist corrosion.

These advancements pave the way for smarter, longer-lasting motion systems.

Eco-Friendly Manufacturing Approaches

Manufacturers are adopting sustainable practices such as:

Using recyclable materials like stainless steel

Reducing waste through precision machining

Employing energy-efficient heat treatments

Green manufacturing ensures both product quality and environmental responsibility.

Cost vs. Performance Analysis

While linear ball bearing slides can be pricier than plain slides, their benefits far outweigh the cost:

Lower friction reduces energy use

Fewer replacements lower long-term costs

Better accuracy enhances product quality

It’s an investment that pays off through efficiency and reliability.

Case Study: Linear Ball Bearing Slide in Automation

An electronics manufacturer implemented linear ball bearing slides in its PCB assembly line. The results were outstanding:

30% increase in production speed

50% reduction in maintenance downtime

Consistent accuracy after 18 months of continuous use

Such real-world examples highlight the system’s reliability and precision.

Precision and Stability in CNC Machines

In CNC systems, a linear ball bearing slide guarantees the fine movements needed for complex machining. It minimizes backlash, maintains rigidity, and ensures high repeatability—key factors in producing precision parts.

Safety and Operational Guidelines

Always install protective covers to prevent debris entry.

Use only manufacturer-recommended lubricants.

Avoid excessive load and vibration.

Follow torque specifications during assembly.

Adhering to these standards ensures both operator safety and system longevity.

Global Market Overview

The linear ball bearing slide market continues to expand, driven by automation, robotics, and industrial digitization. Top players include THK, Hiwin, NSK, Misumi, and Bosch Rexroth. Asia remains a leading region for both manufacturing and innovation.

Future of Linear Ball Bearing Slide

Future trends include:

Integration with IoT systems

Smart sensors for real-time wear detection

Lightweight, corrosion-resistant materials

Predictive maintenance through AI analytics

As automation evolves, linear ball bearing slides will remain a cornerstone of precision engineering.

Expert Tips for Longevity

Keep rails clean and dry.

Maintain regular lubrication cycles.

Inspect preload and alignment periodically.

Avoid shock loads and excessive speeds.

These small practices ensure years of seamless performance.

FAQs

What is a linear ball bearing slide used for?

It’s used to achieve precise linear motion in applications such as CNC machines, 3D printers, and automation systems.

How does it differ from a roller guide?

Ball bearing slides provide smoother, low-friction motion, while roller guides handle higher loads but require more space.

Do linear ball bearing slides need lubrication?

Yes, regular lubrication minimizes wear and keeps motion smooth.

Can I install one without specialized tools?

Yes, but precise alignment tools are recommended for best results.

How long do linear ball bearing slides last?

With proper care, they can last for tens of thousands of operating hours.

Are they suitable for cleanroom environments?

Absolutely, especially stainless steel models with sealed bearings.

Conclusion

The linear ball bearing slide is a marvel of engineering that combines precision, durability, and smooth operation. Its low-friction design and superior motion control make it indispensable in modern manufacturing and automation. As industries continue evolving toward smarter, more efficient systems, these slides will remain the trusted backbone of mechanical precision.

Inbound Link Suggestions:

Link to “CNC Machine Precision Alignment Guide”

Link to “Automation System Maintenance Checklist”

Outbound Link Suggestions: