In the complex world of automation, CNC machining, robotics, and industrial automation, linear bearing slide rail systems serve as the heart of precise linear movement. They ensure smooth, stable, and frictionless motion, allowing modern machinery to achieve consistent accuracy and efficiency.

At YH Linear, we take pride in designing and manufacturing high-performance linear bearing slide rails that define engineering precision. Crafted with advanced materials and cutting-edge production technologies, our bearing rails ensure maximum rigidity, minimal friction, and exceptional service life.

This in-depth article explores everything you need to know about linear bearing slide rail systems—their working principles, structure, materials, types, applications, maintenance, and why YH Linear stands at the forefront of this industry.

Outline

| Section | Heading |

|---|---|

| 1 | Introduction to Linear Bearing Slide Rail |

| 2 | What Is a Linear Bearing Slide Rail? |

| 3 | How Linear Bearing Slide Rails Work |

| 4 | Main Components of a Linear Bearing Slide Rail |

| 5 | Design and Construction Principles |

| 6 | Materials and Surface Treatments |

| 7 | Why Choose Linear Bearing Slide Rails? |

| 8 | Advantages of YH Linear Bearing Slide Rails |

| 9 | Types of Linear Bearing Slide Rails |

| 10 | Linear Ball Bearing Slide Rails |

| 11 | Linear Roller Bearing Slide Rails |

| 12 | Miniature Linear Bearing Slide Rails |

| 13 | Heavy-Duty Linear Bearing Slide Rails |

| 14 | Aluminum Linear Bearing Slide Rails |

| 15 | Linear Bearing Slide Rails vs Linear Guides |

| 16 | Key Factors to Consider Before Selection |

| 17 | Installation Guidelines and Best Practices |

| 18 | Lubrication and Maintenance |

| 19 | Common Problems and Troubleshooting |

| 20 | Linear Bearing Slide Rails in CNC Machinery |

| 21 | Applications in Robotics and Automation |

| 22 | Applications in Medical and Semiconductor Equipment |

| 23 | Customization with YH Linear |

| 24 | YH Linear Quality Control and Manufacturing Standards |

| 25 | Future of Linear Bearing Slide Rails |

| 26 | FAQs |

| 27 | Conclusion |

Linear Bearing Slide Rail

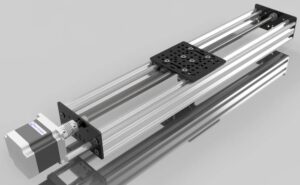

A linear bearing slide rail is a precision mechanical assembly that allows for smooth, low-friction linear motion along a straight path. It consists of a guide rail and a bearing block (or carriage) that contains rolling elements.

YH Linear’s bearing slide rails are engineered to maintain micron-level precision even under demanding conditions, ensuring optimal motion control in every application—from automated production lines to medical robotics.

What Is a Linear Bearing Slide Rail?

A linear bearing slide rail provides guided linear motion by reducing surface contact friction through rolling elements, typically steel balls or cylindrical rollers. Unlike plain bearings, these systems use rolling contact to provide consistent, wear-resistant, and smooth movement.

In essence, the bearing slide rail acts as a precision track, while the bearing block serves as the mobile platform that moves along it. Together, they deliver the stability and accuracy necessary for precision equipment.

How Linear Bearing Slide Rails Work

The principle behind linear bearing slide rails is simple yet powerful: rolling motion instead of sliding friction.

When the carriage moves, steel balls or rollers circulate within the bearing block, supported by internal return paths. This ensures continuous, uniform motion while minimizing resistance.

At YH Linear, our bearing rails are crafted with optimized raceway geometry to distribute loads evenly and reduce vibration, ensuring a longer lifespan and smoother operation.

Main Components of a Linear Bearing Slide Rail

| Component | Function |

|---|---|

| Guide Rail | Provides the track for motion, precision-ground and hardened. |

| Bearing Block (Carriage) | Houses the rolling elements that move along the rail. |

| Rolling Elements | Balls or rollers that reduce friction and support the load. |

| End Caps | Direct the return path of rolling elements. |

| Seals | Prevent dust, debris, and contaminants from entering the system. |

| Lubrication System | Ensures consistent grease or oil flow for longevity. |

YH Linear designs every component with meticulous precision, ensuring flawless assembly and optimal alignment.

Design and Construction Principles

A linear bearing slide rail must balance rigidity, load capacity, and precision.

At YH Linear, we employ:

High-precision CNC machining for dimensional accuracy.

Vacuum heat treatment for hardness and stability.

Automated grinding for mirror-finish raceways.

These measures guarantee consistent, vibration-free performance even under heavy loads.

Materials and Surface Treatments

The choice of materials defines performance longevity.

YH Linear uses:

High-carbon steel for rigidity and durability.

Stainless steel for corrosion resistance.

Aluminum alloys for lightweight motion systems.

We also apply advanced surface coatings:

Chrome plating for anti-wear resistance.

Nickel coating for corrosion protection.

Black oxide finish for enhanced appearance and oxidation resistance.

Why Choose Linear Bearing Slide Rails?

Because precision matters.

Linear bearing slide rails ensure:

High accuracy of linear motion.

Reduced friction and energy consumption.

Higher rigidity and stability for complex operations.

Longer lifespan due to even load distribution.

YH Linear designs rails that guarantee repeatable motion for demanding environments like CNC machines and robotic systems.

Advantages of YH Linear Bearing Slide Rails

Ultra-smooth operation with low friction coefficient.

High load-bearing capacity across all directions.

Exceptional rigidity for minimal deflection.

Corrosion and wear resistance with protective coatings.

Customizable dimensions to suit unique industrial needs.

Energy-efficient performance through optimized design.

Every YH Linear rail undergoes extensive quality inspection before shipment.

Types of Linear Bearing Slide Rails

Ball Bearing Type – For high-speed and smooth motion.

Roller Type – For heavy loads and stiffness.

Miniature Type – For compact and lightweight applications.

Aluminum Type – For portable and cleanroom environments.

Heavy-Duty Type – For industrial and machining systems.

Linear Ball Bearing Slide Rails

These are the most common type, featuring recirculating ball bearings for low friction and high speed.

YH Linear’s ball bearing rails are ideal for 3D printers, optical instruments, and automation lines—offering quiet operation and minimal maintenance.

Linear Roller Bearing Slide Rails

Roller types use cylindrical rolling elements that offer higher contact surface area, resulting in greater rigidity.

Perfect for CNC machining, packaging equipment, and factory automation, these are engineered for endurance and precision.

Miniature Linear Bearing Slide Rails

Miniature slides such as YH Linear MGN series (e.g., MGN9, MGN12) are widely used in semiconductor tools and laboratory automation.

They provide compact size without sacrificing accuracy or performance.

Heavy-Duty Linear Bearing Slide Rails

When handling massive loads or large assemblies, heavy-duty slides are essential.

YH Linear’s reinforced blocks and thickened raceways deliver outstanding stability and rigidity, even in extreme conditions.

Aluminum Linear Bearing Slide Rails

Lightweight, corrosion-resistant, and perfect for high-speed systems, aluminum rails offer versatility.

YH Linear’s aluminum slide rails provide smooth travel with minimal weight—ideal for robotic arms and cleanroom applications.

Linear Bearing Slide Rails vs Linear Guides

| Feature | Linear Bearing Slide Rail | Linear Guide |

|---|---|---|

| Friction Type | Rolling | Rolling or sliding |

| Speed | High | Moderate |

| Rigidity | High | Moderate to high |

| Load Capacity | Excellent | High |

| Applications | Robotics, automation, CNC | General machinery |

Both share similar concepts, but slide rails emphasize load support, smoothness, and compactness, making them indispensable in high-precision environments.

Key Factors to Consider Before Selection

Load requirements (radial, axial, moment).

Motion accuracy needed.

Environmental conditions (temperature, dust, humidity).

Mounting space and configuration.

Maintenance frequency and lubrication accessibility.

YH Linear engineers collaborate with clients to choose the best configuration for optimal results.

Installation Guidelines and Best Practices

Ensure flat, clean mounting surfaces.

Align rails accurately using dowel pins or alignment jigs.

Tighten bolts gradually in sequence.

Move carriage manually after installation to test smooth motion.

Avoid contaminants during assembly.

YH Linear provides installation support manuals and CAD resources for every model.

Lubrication and Maintenance

Proper lubrication prevents premature wear.

Use YH Linear’s recommended grease or compatible oil.

Apply every 500–1000 operational hours.

Keep seals and end caps intact.

Clean rails periodically to remove dust.

For maintenance-free use, self-lubricating options are available at YH Linear.

Common Problems and Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Noise or rough movement | Contamination or misalignment | Clean, re-grease, realign |

| Sticking carriage | Debris or preload issues | Clean and adjust preload |

| Uneven motion | Rail misalignment | Reinstall with precision tools |

| Wear or rust | Insufficient lubrication | Reapply lubricant and use covers |

YH Linear’s technical team provides on-site support and replacement guidance when necessary.

Linear Bearing Slide Rails in CNC Machinery

CNC systems rely on stable linear bearings for cutting precision.

YH Linear’s rails guarantee repeatable accuracy, low vibration, and long tool life, supporting every axis of motion with precision.

Applications in Robotics and Automation

In robotics, speed and accuracy define performance.

YH Linear’s bearing rails enable fluid motion in robotic arms, pick-and-place systems, and industrial assembly lines, boosting productivity and reliability.

Applications in Medical and Semiconductor Equipment

The medical and semiconductor sectors demand ultra-clean, vibration-free environments.

YH Linear’s stainless steel linear bearing slide rails meet stringent standards for cleanroom compatibility and corrosion resistance.

Customization with YH Linear

YH Linear offers flexible customization:

Tailored rail lengths

Different preload classes

Material and coating variations

OEM labeling and branding options

Every project benefits from personalized engineering consultation for optimal system integration.

YH Linear Quality Control and Manufacturing Standards

Our production integrates:

CNC grinding and honing technology

Surface finish inspection under microscopes

Hardness and straightness verification

Load capacity testing

YH Linear adheres to ISO 9001 quality management systems, ensuring product consistency and reliability.

Future of Linear Bearing Slide Rails

With the rise of AI-driven manufacturing and smart automation, linear bearing slide rails are evolving rapidly.

YH Linear is pioneering advancements like:

Smart sensor integration for predictive maintenance

Eco-friendly coatings

Lightweight materials for energy-efficient systems

The future of linear motion will be faster, smarter, and more sustainable — and YH Linear is leading that transformation.

FAQs

What is the purpose of a linear bearing slide rail?

It enables precise, low-friction motion for machinery requiring accurate linear displacement.

How long do YH Linear slide rails last?

With proper lubrication, they can exceed 20,000 hours of operational use.

Can I order custom lengths from YH Linear?

Yes, we manufacture rails tailored to your specific requirements.

Are these bearings suitable for high-speed applications?

Absolutely. YH Linear rails are engineered for high-speed, low-noise operation.

Do YH Linear products come pre-lubricated?

Yes, all units are pre-lubricated and ready for immediate installation.

Are stainless-steel models available?

Yes, YH Linear offers stainless steel options for cleanroom and corrosive environments.

Conclusion

Linear bearing slide rails represent the essence of precision and reliability in modern machinery. They support the industries that shape our world—from robotics to aerospace, from CNC machining to medical innovation.

At YH Linear, our mission is to engineer motion components that push performance boundaries. Each rail reflects our commitment to excellence, quality, and innovation. Whether your application demands compact design, heavy load endurance, or exceptional accuracy, YH Linear provides the perfect linear motion solution.

Inbound Link Suggestions:

Link to: “Linear Guides Rails” (internal)

Link to: “Miniature Linear Slide Bearings” (internal)

Outbound Link Suggestions:

Link to: YH Linear Official Website