Outline for “Linear Bearing Slides”

| Main Topic | Subtopics |

|---|---|

| Introduction | Why smooth motion matters in engineering |

| Linear Bearing Slides | Definition and overview |

| History of Linear Motion Slides | From simple grooves to advanced designs |

| Core Components | Rails, carriages, ball or roller bearings |

| How Linear Bearing Slides Work | Rolling contact, preloading, accuracy |

| Types of Linear Bearing Slides | Ball bearing, roller, plain, crossed roller |

| Key Features | Load capacity, accuracy, rigidity |

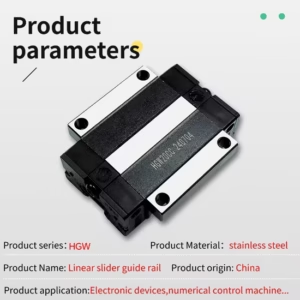

| Materials Used | Steel, aluminum, polymers |

| Use in CNC Machines | Precision in cutting and milling |

| Applications in Robotics | Smooth automation and robotic arms |

| Role in 3D Printing | Accuracy in additive manufacturing |

| Benefits of Linear Bearing Slides | Smoothness, durability, reliability |

| Common Issues | Contamination, wear, misalignment |

| Maintenance Best Practices | Cleaning, lubrication, inspection |

| Choosing the Right Slide | Factors like load, speed, environment |

| Linear Slides vs. Other Motion Systems | Comparisons with rails and shafts |

| DIY and Maker Projects | Using slides in 3D printers and hobby builds |

| Cost Considerations | Price ranges and influencing factors |

| Top Manufacturers | Hiwin, THK, NSK, Bosch Rexroth |

| Industry-Specific Uses | Aerospace, medical, automotive, electronics |

| Innovations in Linear Slides | Smart systems and self-lubricating tech |

| Future of Linear Bearing Slides | IoT integration and smart monitoring |

| Troubleshooting Problems | Noise, stiffness, uneven wear |

| Safety Considerations | Handling and correct installation |

| Environmental Impact | Sustainable materials and recycling |

| FAQs | Most common user questions |

| Conclusion | Key takeaways and outlook |

Introduction

In modern engineering and automation, smooth precision motion is the backbone of productivity. Machines that cut, shape, print, or assemble depend on movement systems that can operate with accuracy and consistency. One such system is the linear bearing slide, a critical component that ensures stability, reliability, and flawless repeatability.

Imagine a CNC machine carving out aerospace components or a 3D printer layering complex designs. Without linear bearing slides, such tasks would suffer from vibration, inaccuracies, or excessive wear. These slides don’t just support motion — they perfect it.

Linear Bearing Slides

At its core, a linear bearing slide is a mechanism designed to provide low-friction, straight-line movement. It typically consists of a rigid base rail and a moving block or carriage that houses ball or roller bearings. As the slide moves, rolling elements circulate inside, ensuring smooth, controlled travel.

Unlike traditional sliding systems, which rely on direct surface contact, linear bearing slides reduce friction by replacing sliding with rolling. This makes them far more durable, accurate, and reliable, even under heavy loads or continuous operation.

Applications span across CNC machining, robotics, packaging, 3D printing, and even medical devices — essentially anywhere precise linear movement is essential.

History of Linear Motion Slides

The origins of linear slides can be traced back to ancient grooves and sledges, where materials were moved along lubricated channels. While crude, these systems laid the groundwork for controlled linear motion.

The Industrial Revolution brought dovetail slides, which offered a more refined guiding system for machine tools. However, these relied on sliding friction, which limited speed and longevity.

The game-changer came in the 20th century with the invention of recirculating ball bearings. By integrating rolling elements into slides, engineers drastically reduced friction. This innovation evolved into the modern linear bearing slide, capable of micrometer-level accuracy, high speeds, and long service life.

Today, with advancements like self-lubricating materials and smart sensors, linear slides are more efficient and reliable than ever.

Core Components

Every linear bearing slide includes carefully engineered parts that work together for seamless motion:

Rail/Base Track: The rigid foundation, often made of hardened steel or aluminum, that guides the carriage.

Carriage (Slide Block): The moving platform that houses the bearings and supports loads.

Rolling Elements: Ball or roller bearings that minimize friction and enable smooth motion.

End Caps & Retainers: Keep the rolling elements in circulation, preventing jams or misalignment.

Lubrication System: Grease fittings or built-in reservoirs to reduce wear and extend service life.

Each component is precision-manufactured because even the smallest defect can lead to misalignment or uneven wear.

How Linear Bearing Slides Work

The working principle of linear bearing slides is both simple and sophisticated. Instead of surfaces sliding against each other, rolling elements inside the carriage rotate as the block moves along the rail. This significantly reduces friction.

For improved stability, many slides use preloading, where the bearings are slightly compressed against the rail. This eliminates play or wobble, ensuring rigid, vibration-free motion even under heavy loads.

The outcome? Motion systems that deliver smooth, repeatable, and highly accurate linear movement for demanding industrial and scientific applications.

Types of Linear Bearing Slides

Linear bearing slides are not a one-size-fits-all solution. Different industries and projects require varying levels of precision, load capacity, and durability. Here are the main types:

Ball Bearing Slides: The most common type, known for smooth, quiet operation. They use recirculating ball bearings to minimize friction, making them ideal for CNC machines and robotics.

Roller Bearing Slides: Instead of balls, these use cylindrical rollers. They can handle heavier loads and provide greater stiffness, making them suitable for industrial equipment.

Plain Bearing Slides: Also called sleeve slides, they rely on sliding contact rather than rolling. While less smooth, they are cheaper, simple to maintain, and work well in dirty environments.

Crossed Roller Slides: Rollers are arranged in a crisscross pattern, allowing them to handle loads from multiple directions. They are preferred in optical systems and semiconductor manufacturing, where ultra-high precision is essential.

Each type has trade-offs. For example, a ball bearing slide may be perfect for a 3D printer, but a roller slide would be better for a heavy-duty industrial press.

Key Features

When selecting a linear bearing slide, engineers evaluate several critical features:

Load Capacity: How much weight the slide can carry without deflecting or wearing out.

Accuracy: The precision with which the slide maintains its linear path.

Rigidity: Resistance to bending, twisting, or vibration under load.

Smoothness: How seamlessly the carriage moves without resistance or chatter.

Durability: Lifespan under continuous use, often measured in millions of cycles.

Noise Level: Important in applications like medical devices or electronics assembly where quiet operation is necessary.

These features make linear bearing slides highly versatile, from delicate laboratory instruments to rugged factory machines.

Materials Used

The materials used in linear bearing slides play a huge role in their performance:

Hardened Steel: Provides durability, high load capacity, and resistance to wear. Standard choice for heavy-duty applications.

Stainless Steel: Corrosion-resistant, making it perfect for food processing, medical, or cleanroom environments.

Aluminum: Lightweight and easy to machine, used in aerospace and compact machinery.

Polymer Bearings and Coatings: Reduce noise and friction, while also protecting against contamination.

Hybrid Materials: Combine steel with polymer or ceramic components for specialized performance.

Choosing the right material depends on factors like environment, budget, and load requirements. For instance, a woodworking CNC may use steel slides with protective covers, while a hospital device might need stainless steel slides for sterilization.

Use in CNC Machines

CNC machines (Computer Numerical Control) rely heavily on linear bearing slides for accuracy and reliability. Whether milling, drilling, or cutting, slides ensure the cutting head or table moves precisely along its programmed path.

Key advantages in CNC applications:

Micrometer Precision: Essential for parts in aerospace, automotive, and electronics.

Stability Under Load: Slides carry heavy spindles and workpieces without deflection.

Reduced Vibration: Ensures smoother cuts and extends tool life.

Durability: Withstands the high-speed, repetitive motions of CNC production.

Without linear bearing slides, CNC machining would lose its accuracy and repeatability, rendering it ineffective for modern manufacturing demands.

Applications in Robotics

In robotics, linear bearing slides are indispensable. Robots must move with accuracy, speed, and repeatability, and slides make that possible.

Pick-and-Place Robots: Slides allow fast, smooth movements when transferring components on assembly lines.

Medical Robots: Used in surgeries, where millimeter-level accuracy can be life-saving.

Collaborative Robots (Cobots): Slides provide safe, stable motion for robots working alongside humans.

Logistics and Warehousing: Linear slides help automated systems move goods efficiently and reliably.

The rise of robotics in manufacturing, healthcare, and logistics is directly tied to the performance of linear bearing slides.

Role in 3D Printing

3D printing, whether hobbyist or industrial, depends on precise movement systems. Linear bearing slides are often used in printers to guide the print head and build plate.

Benefits include:

Accurate Layering: Ensures each layer of material is placed exactly where it should be.

Reduced Print Errors: Slides minimize vibration, preventing misalignment or warping.

Faster Printing: High-quality slides allow quicker movement without sacrificing accuracy.

Customization: Many enthusiasts upgrade budget printers with linear slides to achieve professional-grade results.

Industrial printers, which produce aerospace and medical components, rely on advanced linear slides to guarantee flawless outcomes.

Benefits of Linear Bearing Slides

So, why are linear bearing slides the preferred choice across industries? Their advantages include:

Superior Precision: Critical in industries where tolerances are measured in microns.

Long Service Life: Designed to last millions of cycles with proper care.

Smooth, Quiet Operation: Essential for labs, hospitals, and high-tech environments.

Load Handling: Capable of carrying both light and heavy payloads.

Energy Efficiency: Reduced friction means less power is needed to drive motion.

Versatility: From DIY projects to industrial machinery, they adapt to many applications.

This combination of performance and reliability is why they remain a cornerstone of modern automation.

Common Issues

Despite their strengths, linear bearing slides are not immune to problems:

Contamination: Dust, dirt, or debris can clog bearings and cause uneven motion.

Misalignment: Poor installation leads to binding, noise, and premature wear.

Overloading: Exceeding rated weight capacity can deform bearings and rails.

Lubrication Failures: Without proper lubrication, friction increases dramatically.

Wear Over Time: Even hardened steel can develop grooves after extensive use.

Recognizing these issues early can prevent costly downtime.

Maintenance Best Practices

Maintaining linear bearing slides ensures long-lasting performance. Here’s what to keep in mind:

Regular Cleaning: Remove dust, chips, and other contaminants from rails and bearings.

Lubrication: Follow manufacturer guidelines for oil or grease application.

Visual Inspection: Look for scratches, wear marks, or damaged seals.

Alignment Checks: Ensure slides are installed parallel and properly secured.

Use of Covers: Employ bellows, wipers, or shields in dusty or wet environments.

Proper maintenance not only extends the life of the slides but also ensures machines continue running at peak precision.

Choosing the Right Slide

Selecting the right linear bearing slide depends on a combination of factors. Engineers and DIY enthusiasts alike must balance cost, performance, and environment to find the perfect fit. Key considerations include:

Load Capacity: How heavy is the component or workpiece the slide must carry? Overloading reduces life span.

Speed Requirements: High-speed applications demand bearings that can withstand rapid motion without overheating.

Accuracy Needs: Micron-level tolerances in industries like aerospace require high-precision slides.

Operating Environment: Dusty factories, sterile hospitals, and outdoor applications each require specific materials and seals.

Budget: While high-end slides offer exceptional performance, economical options may suffice for hobby projects.

The wrong choice can lead to inefficiency, wear, or even complete system failure. Taking time to evaluate these factors ensures long-term success.

Linear Slides vs. Other Motion Systems

When it comes to linear motion, slides are often compared with other guiding systems like rails or shafts. Each has unique strengths and weaknesses:

| Feature | Linear Slides | Linear Rails | Linear Shafts |

|---|---|---|---|

| Precision | High, ideal for CNC & robotics | Very high, used in heavy machinery | Moderate |

| Load Capacity | Excellent | Excellent | Limited |

| Smoothness | Very smooth with ball/roller bearings | Very smooth | Smooth but less accurate |

| Durability | Long-lasting with proper maintenance | Extremely durable | Prone to bending |

| Cost | Moderate to high | Higher | Lower |

Linear bearing slides stand out for their balance of precision and durability, making them the go-to choice for most modern applications.

DIY and Maker Projects

It’s not just large industries that benefit from linear bearing slides. Makers, hobbyists, and DIY engineers use them in creative projects, including:

3D Printers: Upgrading budget models for smoother prints.

CNC Routers: Building custom wood- or metal-cutting machines.

Camera Sliders: Ensuring smooth video shooting for content creators.

Robotic Arms: Creating low-cost automation for home labs or workshops.

Laser Cutters and Engravers: Achieving precision in cutting materials.

The availability of affordable slides from suppliers like Amazon, AliExpress, and specialized hardware stores has made precision engineering accessible to enthusiasts worldwide.

Cost Considerations

The cost of linear bearing slides varies widely depending on factors like size, material, precision, and brand.

Entry-Level Slides: $20–$50, suitable for DIY projects and hobbyist 3D printers.

Mid-Range Slides: $100–$300, commonly used in small CNC machines and robotics.

High-End Industrial Slides: $500–$2,000+, designed for aerospace, medical, and factory automation.

Factors that influence price include:

Tolerance levels (higher accuracy = higher cost).

Material quality (stainless steel and hybrid materials are more expensive).

Brand reputation (established brands cost more but ensure reliability).

Added features like self-lubrication or anti-corrosion coatings.

While cost is important, compromising on quality can lead to breakdowns and higher long-term expenses.

Top Manufacturers

Several leading companies dominate the linear bearing slide market, offering proven reliability:

Hiwin: Known for high-precision slides widely used in CNC and robotics.

THK: A Japanese company that pioneered linear motion systems.

NSK: Offers durable slides with advanced sealing and lubrication technology.

Bosch Rexroth: Renowned for German engineering and industrial-grade components.

IKO: Specializes in compact, high-performance slides for specialized applications.

Choosing a reputable manufacturer ensures quality and long-term performance. Many low-cost alternatives exist, but they may lack the durability required for demanding tasks.

Industry-Specific Uses

Linear bearing slides are used in nearly every modern industry:

Aerospace: Precision machining of aircraft parts.

Medical Devices: Used in imaging systems, surgical robots, and laboratory equipment.

Automotive: Essential for robotic assembly lines and CNC machining of engine components.

Electronics: Enables micrometer accuracy in semiconductor manufacturing.

Packaging & Logistics: Guides fast, repetitive movements in automated packaging lines.

The adaptability of linear slides is one reason they remain indispensable across so many fields.

Innovations in Linear Slides

Linear bearing slides are evolving with technology. Some exciting innovations include:

Self-Lubricating Slides: Built-in lubrication reduces maintenance and downtime.

Smart Sensors: Embedded sensors monitor wear, temperature, and vibration.

Lightweight Materials: Aluminum and carbon composites reduce weight without sacrificing strength.

Noise-Reduction Technology: Special coatings and polymer bearings allow near-silent operation.

Modular Designs: Easy to install, replace, or upgrade in existing machines.

These advances are pushing linear slides beyond traditional engineering, making them smarter and more efficient.

Future of Linear Bearing Slides

The future looks bright for linear bearing slides, especially with the rise of Industry 4.0 and smart manufacturing. We can expect:

Integration with IoT systems for real-time monitoring.

Predictive maintenance using AI algorithms.

Greater use of sustainable materials.

Miniaturization for use in electronics and nanotechnology.

Expansion into consumer products, such as advanced home robotics.

As automation becomes more widespread, the demand for precise, durable, and intelligent linear slides will only grow.

Troubleshooting Problems

When problems arise, quick troubleshooting can prevent costly downtime.

Noise During Movement: Likely due to poor lubrication or contamination.

Uneven Motion or Binding: Caused by misalignment during installation.

Reduced Accuracy: Often due to wear on bearings or rails.

Excessive Vibration: May result from overloading or lack of preloading.

Shortened Life Span: Typically linked to poor maintenance or using the wrong slide for the job.

By diagnosing early, engineers can replace or repair components before major failures occur.

Safety Considerations

Like all mechanical systems, linear bearing slides require proper safety measures:

Correct Installation: Improper alignment can cause catastrophic failure.

Weight Limits: Never exceed rated capacity.

Protective Gear: Operators should wear gloves when handling sharp rails.

Secure Mounting: Loose slides can lead to sudden machine failures.

Regular Inspections: Prevent accidents caused by unexpected breakdowns.

Safety is especially important in high-speed machines, where failures could pose risks to both operators and equipment.

Environmental Impact

Sustainability is a growing concern in engineering, and linear bearing slides are no exception.

Recyclable Materials: Steel and aluminum slides can be recycled.

Energy Efficiency: Reduced friction lowers energy consumption.

Eco-Friendly Lubricants: Manufacturers are developing biodegradable lubricants.

Durability: Longer life spans mean fewer replacements and less waste.

The shift toward greener technologies is influencing how slides are designed, manufactured, and maintained.

FAQs

What are linear bearing slides used for?

They are used in CNC machines, robotics, 3D printers, and medical devices to provide smooth, accurate linear motion.

What’s the difference between ball bearing and roller bearing slides?

Ball bearings offer smooth, precise movement, while roller bearings handle heavier loads and provide greater stiffness.

Do linear bearing slides need lubrication?

Yes, lubrication is essential to reduce friction, extend lifespan, and ensure smooth motion.

How long do linear bearing slides last?

With proper maintenance, they can last millions of cycles. Lifespan depends on load, speed, and environment.

Can I use linear bearing slides in DIY projects?

Absolutely. They are commonly used in hobbyist CNC machines, 3D printers, and camera sliders.

Are linear bearing slides expensive?

Prices vary widely, from affordable options for DIY builds to high-end industrial slides costing thousands.

Conclusion

Linear bearing slides may look simple, but they are the unsung heroes of precision motion. From aerospace and medicine to robotics and DIY projects, these systems deliver smooth, reliable, and accurate movement. Their versatility, durability, and ongoing innovations ensure they will remain at the heart of modern engineering for decades to come.

If you’re building, upgrading, or maintaining any machine that requires flawless motion, investing in the right linear bearing slide is the key to long-term success.

Suggested Inbound Links:

[Linear Rails and Slides Guide]

[CNC Machine Motion Systems]

[3D Printing Precision Tips]

Suggested Outbound Links: