Outline for “Linear Bearing Guide Rail”

| Main Topic | Subtopics |

|---|---|

| Introduction | Why precision motion matters, role of linear bearing guide rails |

| Linear Bearing Guide Rail | Definition and working principle |

| History of Linear Bearings | Early designs to modern precision rails |

| Core Components | Rails, carriages, ball bearings, lubrication |

| Types of Linear Bearings | Ball bearings, roller bearings, plain bearings |

| Types of Guide Rails | Profiled rails, round rails, miniature rails |

| How Linear Bearing Guide Rails Work | Rolling motion, preloading, and accuracy |

| Materials Used in Guide Rails | Steel, aluminum, polymers |

| Use in CNC Machines | Accuracy in machining and milling |

| Applications in Robotics | Smooth robotic arms and automation |

| Benefits of Linear Bearing Guide Rails | Accuracy, durability, versatility |

| Common Problems | Wear, contamination, misalignment |

| Maintenance Practices | Cleaning, lubrication, inspection |

| Choosing the Right System | Load, environment, and cost factors |

| Rails vs. Shafts | Which to choose for your application |

| Innovations in Linear Bearings | Self-lubricating and smart sensors |

| DIY and Maker Applications | Using linear bearings in 3D printers and projects |

| Cost Factors | Price ranges and quality differences |

| Top Manufacturers | Hiwin, THK, NSK, Bosch Rexroth |

| Industry-Specific Uses | Medical, aerospace, automotive |

| Future of Linear Bearing Guide Rails | Smart manufacturing and IoT integration |

| Troubleshooting Issues | Noise, vibration, uneven wear |

| Safety Considerations | Handling, installation, and operation |

| Environmental Impact | Sustainable materials and recycling |

| FAQs | Common questions answered |

| Conclusion | Key takeaways and future outlook |

Introduction

In the fast-moving world of modern engineering, precision is not a luxury — it’s a necessity. Machines that shape, cut, assemble, or even heal must operate with flawless accuracy. At the heart of this precision lies an unassuming yet powerful innovation: the linear bearing guide rail.

Picture a robotic arm placing delicate electronic components or a CNC machine cutting steel with micrometer accuracy. These tasks would be impossible without a guiding system that allows smooth, reliable, and repeatable motion. Linear bearing guide rails make this possible by combining the strength of rails with the frictionless motion of bearings.

Linear Bearing Guide Rail

A linear bearing guide rail is a motion system designed to move objects smoothly along a straight path with minimal friction. The guide rail provides a rigid track, while the linear bearing — often a block filled with recirculating ball or roller bearings — glides along it.

This pairing ensures that loads can be carried effortlessly while maintaining strict alignment. Unlike simple sliding mechanisms, which wear out quickly, linear bearing guide rails achieve long lifespans, even under heavy loads and constant use.

They are widely used in CNC machines, robotics, 3D printing, medical devices, and automation systems — essentially anywhere smooth and precise linear motion is required.

History of Linear Bearings

The idea of controlled linear motion dates back centuries. Ancient civilizations used rudimentary grooves and lubricants like oil or animal fat to move heavy stones. While effective for their time, these methods lacked precision.

With the rise of industrialization in the 18th and 19th centuries, engineers sought ways to guide machine parts more accurately. Early dovetail slides became common in lathes and milling machines. However, they relied on sliding contact, which generated friction and wear.

The breakthrough came with the invention of ball bearings in the 20th century. By introducing rolling elements into guide systems, engineers dramatically reduced friction. This innovation gave birth to the modern linear bearing guide rail — capable of handling higher speeds, greater loads, and far more precise tolerances.

Today, advanced manufacturing, aerospace, and even medical robotics rely on this technology to achieve levels of accuracy once thought impossible.

Core Components

Every linear bearing guide rail system consists of several key parts:

Guide Rail: A precision-ground track, often made from hardened steel or aluminum.

Bearing Block (Carriage): The moving platform that slides along the rail, housing the rolling elements.

Rolling Elements: Ball or roller bearings that reduce friction and allow smooth motion.

End Caps & Retainers: Components that keep bearings circulating properly.

Lubrication System: Either manual fittings or built-in reservoirs that reduce wear.

Each component plays a vital role. For example, without proper lubrication, even the best rail system can fail quickly due to friction and heat.

Types of Linear Bearings

Linear bearings are not all the same. Different designs serve different purposes:

Ball Bearings: The most common type, offering high precision and smooth motion.

Roller Bearings: Use cylindrical rollers instead of balls, providing greater load capacity and stiffness.

Plain Bearings: Rely on sliding surfaces rather than rolling elements. They are cheaper but less smooth.

Crossed Roller Bearings: Rollers are arranged at 90° angles for superior rigidity and accuracy.

The choice depends on the application. For example, electronics manufacturing requires high precision, while heavy machinery benefits from roller bearings that can handle higher loads.

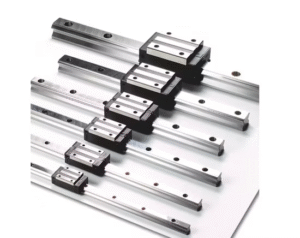

Types of Guide Rails

Just like bearings, guide rails also come in different designs to serve unique applications. The choice of rail impacts how the entire system performs in terms of load, speed, and accuracy.

Profiled Rails: These are the most common, featuring a rectangular cross-section with precisely ground grooves. They offer high rigidity and are preferred for CNC machines and robotics.

Round Rails: As the name suggests, these rails are cylindrical. They are less rigid but allow for easier installation and can tolerate slight misalignments.

Miniature Rails: Designed for compact spaces, miniature rails are used in electronics, small robotics, and medical devices.

Heavy-Duty Rails: Built for large industrial equipment, these rails are designed to handle massive loads and resist bending under pressure.

Choosing between these depends on the balance of cost, performance, and environment. For example, round rails may be sufficient for a simple DIY project, while profile rails are essential for high-precision manufacturing.

How Linear Bearing Guide Rails Work

The beauty of a linear bearing guide rail lies in its simplicity. A rigid rail serves as a track, while a carriage fitted with rolling elements glides along it.

Instead of sliding contact (which creates friction), these systems rely on rolling contact. Tiny ball or roller bearings circulate inside the carriage, allowing smooth motion with minimal resistance. This not only reduces energy consumption but also increases the life span of the system.

Another critical feature is preloading. Bearings are slightly compressed against the rail, removing any gaps that could cause play or vibration. This results in greater stability, ensuring that even under heavy loads or high speeds, the system remains accurate.

In high-precision industries, this mechanism is the backbone of reliability — whether it’s guiding a surgical tool or positioning a 3D printer head with micrometer precision.

Materials Used in Guide Rails

Materials determine how well a linear bearing guide rail performs under specific conditions:

Hardened Steel: Offers durability and high load-bearing capacity. Common in heavy-duty industrial systems.

Stainless Steel: Resistant to rust and corrosion, making it ideal for food processing and medical environments.

Aluminum: Lightweight and easier to machine, used in applications where weight reduction is crucial, such as aerospace.

Polymer-Coated Rails: Reduce noise and provide smoother motion while protecting against wear.

Hybrid Designs: Sometimes combine steel rails with polymer bearings for a balance of performance and cost.

Selecting the right material depends on environmental factors. A CNC machine in a dusty workshop requires steel rails with seals, while a hospital imaging device might use stainless steel for cleanliness and hygiene.

Use in CNC Machines

CNC machines are synonymous with precision, and linear bearing guide rails are their backbone. Without them, achieving consistent, repeatable cuts would be nearly impossible.

Accuracy: Rails ensure that cutting tools follow the programmed path with micrometer precision.

Load Handling: CNC machines often carry heavy spindles and workpieces. Guide rails distribute these loads evenly.

Vibration Reduction: By maintaining rigid alignment, rails prevent chatter and ensure smoother surfaces.

Durability: Rails resist the wear and tear caused by constant high-speed movements.

Consider a CNC milling machine producing aerospace components. Even a tiny error in alignment can lead to rejected parts, wasted material, and lost revenue. With guide rails, manufacturers maintain the consistency required in such demanding industries.

Applications in Robotics

Robotics is another field where linear bearing guide rails shine. Robots require fluid, controlled motion to perform tasks safely and effectively.

Industrial Robots: Rails guide robotic arms used in automotive assembly lines, ensuring precision in welding, painting, and assembly.

Collaborative Robots (Cobots): In factories, cobots work alongside humans. Their rails must provide smooth, quiet, and safe operation.

Medical Robots: In surgeries, precision is non-negotiable. Rails allow for micro-accurate positioning of tools.

Logistics Automation: Rail systems power robotic carts and conveyors that streamline warehouses.

The growing adoption of robotics across industries only strengthens the importance of high-quality linear bearing guide rails.

Benefits of Linear Bearing Guide Rails

So, why do engineers and industries invest in these systems? The benefits are compelling:

High Precision: Essential for industries like aerospace, medicine, and electronics.

Smooth Motion: Reduces wear, noise, and energy usage.

Load Capacity: Handles both lightweight and extremely heavy applications.

Durability: Designed to last through millions of cycles.

Versatility: From hobbyist 3D printers to massive industrial presses, guide rails fit a wide spectrum of uses.

Reduced Maintenance Costs: With proper lubrication, they offer long service life with minimal intervention.

Put simply, they combine strength, reliability, and accuracy in one compact system.

Common Problems

Even the best systems can face challenges. Some of the most common issues include:

Contamination: Dust, dirt, or chips can damage bearings.

Misalignment: Incorrect installation leads to uneven motion and premature wear.

Insufficient Lubrication: Dry rails cause friction, noise, and reduced lifespan.

Overloading: Exceeding weight capacity deforms rails and bearings.

Wear and Tear: Over time, even hardened steel can develop grooves.

Identifying these problems early can save significant repair costs and prevent unexpected downtime.

Maintenance Practices

Proper maintenance extends the life and performance of a linear bearing guide rail. Best practices include:

Regular Cleaning: Wipe rails to remove dirt and debris.

Lubrication: Apply recommended grease or oil to keep rolling elements smooth.

Inspection: Look for uneven wear, strange noises, or stiffness in motion.

Alignment Checks: Ensure parallelism between rails and correct mounting.

Protective Covers: In harsh environments, use bellows or wipers to shield the rails.

These small steps, if followed consistently, can prevent costly breakdowns and ensure continuous precision.