Introduction

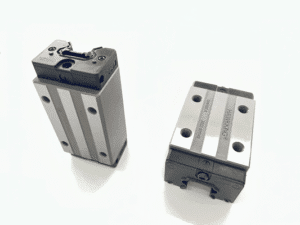

In modern industrial machinery and automation systems, precision linear motion is essential for efficiency, accuracy, and reliability. A core component enabling this motion is the linear carriage, also known as a linear block or linear bearing block.

A linear carriage moves along a linear rail or shaft, supported by rolling elements such as balls or cylindrical rollers, ensuring smooth and low-friction motion. Linear carriages are critical in CNC machines, 3D printers, automated assembly lines, robotics, and material handling equipment.

Compared with traditional sliding systems, linear carriages provide higher precision, lower friction, and better load distribution, making them ideal for heavy-duty and high-speed applications.

This article provides a detailed overview of linear carriages, including their definition, structure, working principles, types, materials, advantages, applications, selection guidelines, installation, and maintenance.

What Is a Linear Carriage?

A linear carriage is a mechanical component designed to move linearly along a guide rail or shaft, supporting the moving part of a machine while maintaining alignment and stability. It typically contains rolling elements, such as balls or rollers, which circulate within the carriage to reduce friction and wear.

The main functions of a linear carriage include:

Guiding linear motion with precision

Supporting static and dynamic loads

Minimizing friction for smoother operation

Maintaining rigidity and alignment during movement

Linear carriages are often paired with linear rails or shafts, forming a complete linear motion system capable of high-speed, high-precision operation.

Key Components of a Linear Carriage

1. Carriage Body

The main housing of the linear carriage

Provides rigidity and support for rolling elements

Typically made of hardened steel or aluminum

2. Rolling Elements

Steel balls or cylindrical rollers that circulate inside the carriage

Reduce friction and distribute load evenly

3. Raceways

Precision-machined surfaces inside the carriage

Guide the rolling elements along the rail

4. End Caps and Retainers

Maintain rolling element position

Allow smooth circulation

5. Seals and Wipers

Protect internal components from dust, debris, and coolant

Essential in industrial environments

6. Lubrication Channels

Facilitate the application of grease or oil

Ensure smooth operation and long service life

How a Linear Carriage Works

Linear carriages operate based on rolling motion mechanics:

The carriage is mounted on a linear rail or shaft.

Rolling elements circulate within the carriage as it moves along the rail.

Loads are transferred evenly across multiple contact points.

Friction is minimized compared with sliding systems.

Smooth, accurate, and controlled linear motion is achieved.

This system allows machinery to operate with high precision, rigidity, and durability, even under heavy loads or high-speed conditions.

Types of Linear Carriages

1. Ball-Type Linear Carriages

Use recirculating steel balls

Provide smooth motion and high-speed performance

Suitable for CNC machines, 3D printers, and light automation

2. Roller-Type Linear Carriages

Use cylindrical rollers instead of balls

Offer higher rigidity and load capacity

Ideal for heavy machinery and gantry systems

3. Profile Rail Linear Carriages

Rectangular block design with integrated raceways

Multi-directional load support

Most common in CNC machining centers and industrial automation

4. Miniature Linear Carriages

Compact design for small-scale machines

High precision in limited installation space

Used in medical equipment, lab automation, and desktop CNC machines

5. Heavy-Duty Linear Carriages

Reinforced carriage blocks and larger rollers

Designed for extreme loads, shocks, or harsh industrial environments

Materials Used in Linear Carriages

Hardened Bearing Steel – High load capacity and wear resistance

Stainless Steel – Corrosion-resistant for wet or humid conditions

Aluminum Alloy – Lightweight, moderate load applications

Engineering Plastics / Composites – Low noise, chemical-resistant components

Surface Treatments – Chrome plating, black oxide, and induction hardening

Material selection depends on load, speed, environment, and required service life.

Advantages of Linear Carriages

High Precision and Repeatability – Maintains consistent motion

Low Friction and Smooth Operation – Reduces energy loss

High Load Capacity – Supports heavy static and dynamic loads

Rigidity and Stability – Maintains alignment during motion

Long Service Life – Durable with proper maintenance

Versatile Applications – Compatible with horizontal, vertical, and inclined movement

These advantages make linear carriages essential in industrial automation, CNC machining, robotics, and heavy machinery.

Applications of Linear Carriages

Linear carriages are widely used in:

CNC Machines – Lathes, milling centers, gantry systems

Robotics – Linear axes for positioning and movement

3D Printers and Laser Engravers – Precision motion along X, Y, or Z axes

Industrial Automation – Conveyor systems, pick-and-place machines

Material Handling – Heavy-load transfer carts

Packaging Machinery – High-speed, high-precision applications

Medical and Laboratory Equipment – Automated test or dispensing systems

How to Choose the Right Linear Carriage

When selecting a linear carriage, consider:

Load Capacity – Static and dynamic requirements

Precision and Repeatability – Accuracy for the application

Travel Distance and Stroke Length

Speed and Acceleration – Axis motion requirements

Environmental Conditions – Dust, moisture, chemicals, temperature

Maintenance Accessibility – Lubrication and inspection points

Space and Mounting Constraints

Choosing the right carriage ensures stable operation, longer service life, and precise motion.

Installation Best Practices

Mount rails on flat and rigid surfaces

Align carriages carefully to prevent uneven load distribution

Use correct fasteners and torque specifications

Apply lubrication before initial operation

Test under operational loads to verify smooth motion

Proper installation directly impacts accuracy, load distribution, and service life.

Maintenance and Care

Clean rails and carriages regularly to remove dust and debris

Inspect seals, wipers, and rolling elements

Re-lubricate as per manufacturer recommendations

Replace worn or damaged components promptly

Routine maintenance ensures smooth operation, high accuracy, and long service life.

Linear Carriage vs. Linear Bearing

| Feature | Linear Carriage | Standard Linear Bearing |

|---|---|---|

| Load Capacity | High | Moderate |

| Friction | Low | Very low |

| Precision | High | High to very high |

| Rigidity | High | Moderate |

| Maintenance | Low | Moderate |

Linear carriages excel in heavy-duty or high-load applications, while standard linear bearings are used in light-load, precision-sensitive scenarios.

Future Trends in Linear Carriage Technology

Heavy-duty and roller-type carriages for higher load capacity

Maintenance-free or low-maintenance designs

Corrosion-resistant coatings and materials

Integrated sensors for condition monitoring

Smart lubrication systems and IoT-enabled linear axes

These trends support the development of high-performance industrial automation and CNC systems.

Frequently Asked Questions (FAQs)

1. What is a linear carriage used for?

It provides smooth, precise, and load-bearing linear motion in machinery and automation systems.

2. How is a linear carriage different from a linear bearing?

A linear carriage includes the bearing block and rolling elements mounted on a rail, while a standard linear bearing may only be a rolling element guide without a block.

3. Do linear carriages need lubrication?

Yes, lubrication is essential for reducing friction and extending service life.

4. Can linear carriages handle heavy loads?

Yes, heavy-duty and roller-type linear carriages are designed for extreme loads.

5. Which industries use linear carriages most?

CNC machining, robotics, automation, material handling, packaging, and laboratory equipment.

Conclusion

A linear carriage is a key component for precision, smooth, and high-load linear motion. Its rolling-element design provides low friction, high accuracy, and long service life, making it indispensable in CNC machines, robotics, automation systems, and material handling applications.

Proper selection, installation, and maintenance of linear carriages ensure stable operation, increased productivity, and minimal downtime, making them a foundational element of modern industrial machinery.