Outline for Linear Guide Rail Set Article

| Main Topic | Sub-Topics |

|---|---|

| Introduction to Linear Guide Rail Set | Importance in industrial automation and machinery |

| What is a Linear Guide Rail Set? | Definition, structure, and working principle |

| Evolution of Linear Guide Rail Set | From sliding mechanisms to modern rolling systems |

| Core Components of a Linear Guide Rail Set | Rails, carriages, rolling elements, seals, lubrication |

| Types of Linear Guide Rail Sets | Ball-type, roller-type, miniature, heavy-duty |

| How a Linear Guide Rail Set Works | Load transfer, rolling vs. sliding motion |

| Advantages of Linear Guide Rail Set | Precision, efficiency, low friction, rigidity |

| Linear Guide Rail Set vs. Linear Bearings | Key differences, strengths, and weaknesses |

| Applications of Linear Guide Rail Set | CNC, robotics, aerospace, packaging, medical devices |

| Linear Guide Rail Set in CNC Machines | Accuracy, vibration reduction, tool life extension |

| Linear Guide Rail Set in Robotics | Speed, repeatability, and motion flexibility |

| Linear Guide Rail Set in Medical Equipment | Quiet operation, reliability, and smooth positioning |

| Heavy-Duty Use of Linear Guide Rail Set | Shock resistance, large load capacity |

| Material Choices for Linear Guide Rail Set | Steel, stainless steel, ceramic, composites |

| Lubrication and Maintenance of Linear Guide Rail Set | Best practices, grease vs. oil, intervals |

| Common Issues with Linear Guide Rail Set | Misalignment, contamination, wear |

| Troubleshooting Linear Guide Rail Set | Inspections, lubrication fixes, replacement signs |

| Innovations in Linear Guide Rail Set Technology | Smart sensors, self-lubrication, lightweight design |

| Selecting the Right Linear Guide Rail Set | Load, speed, environment, budget factors |

| Installation Best Practices | Alignment, preload, mounting surfaces |

| Cost Considerations of Linear Guide Rail Set | Pricing factors, ROI, lifecycle cost |

| Environmental Impact and Sustainability | Eco-friendly lubrication, corrosion resistance |

| Future Trends in Linear Guide Rail Set | AI-driven monitoring, miniaturization |

| Top Manufacturers of Linear Guide Rail Set | Global leaders, brands, and quality standards |

| FAQs on Linear Guide Rail Set | Answers to industry’s common questions |

| Conclusion on Linear Guide Rail Set | Final thoughts and future importance |

Introduction to Linear Guide Rail Set

In industries where precision, durability, and reliability define success, the linear guide rail set has become a cornerstone of modern engineering. These systems enable machines to achieve smooth and controlled linear motion while carrying significant loads. From CNC machines carving aerospace parts to surgical robots performing life-saving procedures, linear guide rail sets are the invisible yet vital backbone of precision.

Traditional sliding mechanisms often suffered from rapid wear, high friction, and unpredictable accuracy. In contrast, linear guide rail sets incorporate rolling elements such as balls or rollers that ensure smooth, low-resistance movement. This improvement not only enhances performance but also reduces long-term operating costs, making them indispensable across sectors.

What is a Linear Guide Rail Set?

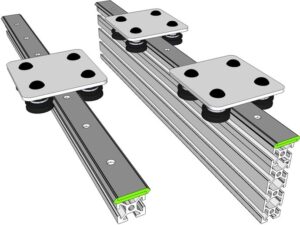

A linear guide rail set is a mechanical assembly designed to provide smooth, guided, and accurate linear motion. At its core, it consists of:

Rails – Hardened steel tracks that define the motion path.

Carriages (Blocks) – Moving platforms fitted with rolling elements.

Rolling Elements – Balls or rollers that reduce friction and distribute load.

Seals and End Caps – Protect the system from dust and contaminants.

Lubrication Ports – Maintain consistent lubrication for extended life.

This system ensures low-friction, vibration-free motion even under demanding conditions. Unlike sliding guides, which lose efficiency over time, linear guide rail sets deliver consistent accuracy for millions of cycles.

Evolution of Linear Guide Rail Set

The roots of linear motion date back to ancient civilizations. The Egyptians used primitive wooden rollers to move heavy stones during pyramid construction. Later, industrial machines adopted sliding blocks made of bronze or cast iron, but these generated excessive friction and required constant lubrication.

The introduction of rolling elements—first with ball bearings, then cylindrical rollers—revolutionized machine design. Linear guide rail sets brought:

Reduced friction – Transforming sliding contact into rolling motion.

Higher load capacity – Distributing forces evenly.

Greater rigidity – Preventing misalignment under stress.

Enhanced lifespan – Withstanding millions of cycles.

Today’s systems are smarter, incorporating corrosion-resistant materials, compact designs, and even embedded sensors for predictive maintenance.

Core Components of a Linear Guide Rail Set

A linear guide rail set is a combination of precision-engineered parts that work together seamlessly:

Guide Rail – Provides the motion path, made of hardened and ground steel.

Carriage/Block – Houses the rolling elements and supports the moving load.

Rolling Elements – Balls for high-speed, light loads; rollers for heavy-duty applications.

End Caps and Seals – Protect against contamination and retain lubrication.

Preload Mechanism – Adjusts tightness to eliminate play and increase rigidity.

Lubrication System – Keeps the rolling elements operating smoothly.

Every part contributes to precision, which is why proper design and maintenance are crucial.

Types of Linear Guide Rail Sets

Linear guide rail sets are classified based on their rolling elements and size:

Ball-Type Guide Rail Sets – Cost-effective, smooth, suitable for medium loads.

Roller-Type Guide Rail Sets – Handle higher loads and offer superior rigidity.

Miniature Guide Rail Sets – Compact and lightweight, used in electronics, optical instruments, and medical devices.

Heavy-Duty Guide Rail Sets – Built for industries like shipbuilding, construction, and mining.

The type chosen depends on load requirements, space constraints, and precision needs.

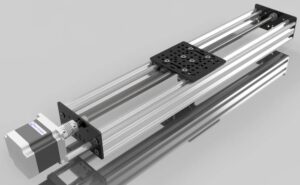

How a Linear Guide Rail Set Works

The principle of operation is straightforward but highly efficient. As the carriage moves along the rail, rolling elements inside the block circulate continuously. Instead of sliding surfaces rubbing together, balls or rollers rotate, drastically reducing resistance.

This design ensures:

Smooth motion with minimal vibration.

Even load distribution that prevents premature wear.

High repeatability in positioning tasks.

Reduced power consumption compared to sliding mechanisms.

In short, they transform motion from laborious sliding to effortless rolling.

Advantages of Linear Guide Rail Set

Linear guide rail sets provide numerous advantages, making them indispensable:

Exceptional precision – Ideal for applications requiring micron-level accuracy.

Rigidity under stress – Maintains alignment even under heavy loads.

Durability – Designed to withstand years of continuous use.

Low maintenance – Especially with self-lubrication features.

Cost savings – Reduced downtime and fewer replacements.

Quiet operation – Critical in medical and laboratory environments.

These benefits directly translate into higher productivity, better product quality, and lower operating costs.

Linear Guide Rail Set vs. Linear Bearings

While both provide linear motion, key differences separate them:

| Feature | Linear Guide Rail Set | Linear Bearing |

|---|---|---|

| Load Capacity | Very high | Moderate |

| Rigidity | Excellent | Lower |

| Precision | Micron-level | Limited |

| Durability | Long service life | Shorter |

| Cost | Higher initial | Lower initial |

| Applications | CNC, robotics, aerospace | Light automation, DIY machinery |

For critical industrial applications, linear guide rail sets clearly outperform traditional bearings.

Applications of Linear Guide Rail Set

Linear guide rail sets are versatile, finding use across diverse industries:

CNC machines – For smooth, accurate tool positioning.

Robotics – To ensure consistent, repeatable movements.

Medical equipment – For patient positioning, imaging, and surgical robots.

Aerospace – Precision in simulators and component manufacturing.

Packaging machinery – High-speed, repetitive operations.

Semiconductors – Cleanroom-compatible motion control.

Their ability to adapt makes them one of the most widely deployed motion systems worldwide.

Linear Guide Rail Set in CNC Machines

CNC machines demand precise, vibration-free motion. A linear guide rail set ensures:

Smooth tool paths for cleaner cuts.

Reduced vibrations during machining.

Extended tool life due to consistent motion.

Higher accuracy in high-speed milling and drilling.

Without them, CNC precision would be compromised, and productivity would suffer.

Linear Guide Rail Set in Robotics

Robots rely heavily on repeatability. A linear guide rail set provides:

High-speed, low-friction movement.

Rigidity for stability during heavy tasks.

Long service life for continuous operation.

Quiet performance suitable for workplaces.

Whether in assembly lines or automated warehouses, guide rails power robotic precision.

Linear Guide Rail Set in Medical Equipment

In healthcare, reliability and silence are essential. Applications include:

MRI and CT scanners – Smooth patient positioning.

Surgical robots – Precise motion of robotic arms.

Laboratory automation – Silent, accurate linear movement.

Here, a linear guide rail set ensures patient safety and doctor confidence.

Heavy-Duty Use of Linear Guide Rail Set

Industries such as mining, shipbuilding, and construction require systems that withstand extreme forces. Roller-type guide rail sets are preferred for:

Load-bearing strength under heavy equipment.

Shock absorption in harsh environments.

Durability under constant stress.

They ensure reliability even in the toughest conditions.

Material Choices for Linear Guide Rail Set

The choice of material affects performance:

Hardened Steel – Standard for strength and durability.

Stainless Steel – Resists corrosion, ideal for cleanrooms.

Ceramics – Lightweight and heat-resistant.

Composites – Reduce weight without sacrificing rigidity.

The right material balances strength, environment resistance, and cost.

Lubrication and Maintenance of Linear Guide Rail Set

Lubrication is key to longevity:

Grease lubrication – Best for heavy loads.

Oil lubrication – Ideal for high-speed systems.

Self-lubrication – Reduces manual maintenance.

Regular inspections for contamination, wear, and lubrication levels prevent costly breakdowns.

Common Issues with Linear Guide Rail Set

Challenges include:

Misalignment causing uneven wear.

Contamination damaging rolling elements.

Insufficient lubrication leading to friction.

Excessive preload creating heat and inefficiency.

Most issues can be prevented with proactive maintenance.

Troubleshooting Linear Guide Rail Set

When problems arise, steps include:

Inspecting rails for scratches or deformation.

Checking lubrication levels.

Realigning rails and carriages.

Replacing worn seals or blocks.

Using sensors for early diagnostics.

Quick troubleshooting ensures minimal downtime.

Innovations in Linear Guide Rail Set Technology

Recent advances include:

Smart sensors – Monitor wear and load in real-time.

Self-lubricating blocks – Eliminate frequent servicing.

Lightweight alloys and composites – Improve speed.

AI-driven predictive maintenance – Reduces failures.

These innovations make systems smarter, longer-lasting, and more efficient.

Selecting the Right Linear Guide Rail Set

Factors to consider:

Load capacity requirements.

Desired speed of operation.

Level of precision needed.

Environmental conditions (dust, moisture, chemicals).

Budget constraints.

Correct selection ensures optimal performance and cost-effectiveness.

Installation Best Practices

To maximize performance:

Ensure mounting surfaces are flat and clean.

Apply preload carefully.

Use proper alignment tools.

Secure lubrication systems before operation.

Correct installation prevents premature wear and ensures long-term accuracy.

Cost Considerations of Linear Guide Rail Set

While initial costs are higher than bearings, long-term savings include:

Reduced downtime.

Longer lifespan.

Lower maintenance costs.

Higher productivity.

When considering lifecycle cost, they are more economical.

Environmental Impact and Sustainability

Linear guide rail sets contribute positively by:

Reducing energy consumption due to low friction.

Using eco-friendly lubricants.

Offering corrosion-resistant materials for longer use.

Their durability reduces industrial waste and replacement needs.

Future Trends in Linear Guide Rail Set

The next wave of improvements includes:

AI-powered monitoring for predictive failure analysis.

Miniaturized guide rails for nanotech and micro-robotics.

Eco-friendly lubrication systems for sustainability.

Hybrid composite materials for lightweight, durable designs.

These trends point toward smarter, greener, and faster motion systems.

Top Manufacturers of Linear Guide Rail Set

Some of the leading brands include:

THK (Japan) – Pioneer in guideway innovation.

Hiwin (Taiwan) – Affordable and high-quality.

NSK (Japan) – Known for precision and reliability.

Bosch Rexroth (Germany) – Leader in heavy-duty solutions.

IKO (Japan) – Compact designs for specialized needs.

Each of these companies sets industry benchmarks in performance.

FAQs on Linear Guide Rail Set

What is the purpose of a linear guide rail set?

It provides smooth, precise, low-friction linear motion for machines.

How long does a linear guide rail set last?

With proper care, 10–20 years of service is common.

Ball or roller—what’s better?

Balls for lighter, faster tasks; rollers for heavy-duty loads.

Do they require lubrication?

Yes, lubrication is essential for long-term performance.

Can they be used in cleanrooms?

Yes, stainless steel versions with seals are ideal for medical and semiconductor industries.

Are linear guide rail sets expensive?

They have higher upfront costs but lower lifetime costs compared to alternatives.

Conclusion on Linear Guide Rail Set

The linear guide rail set is one of the most critical enablers of precision engineering today. By offering smooth, efficient, and reliable linear motion, it has transformed industries ranging from CNC machining to medical robotics.

Its advantages—rigidity, durability, accuracy, and energy efficiency—make it indispensable in modern automation. With innovations like AI-driven monitoring and self-lubrication, its role in the future of engineering is only set to grow stronger.

Simply put, the linear guide rail set is not just a component—it’s the foundation of precision and productivity in industrial motion.

🔗 Suggested Inbound Links

CNC machining accuracy systems

Robotics automation parts

Industrial lubrication best practices