Outline for Linear Guide Slider

| Section | Subtopics |

|---|---|

| Introduction | Why linear motion matters, overview of linear guide slider |

| Linear Guide Slider | Definition, role in engineering and automation |

| History of Linear Guides | Evolution from bushings to modern sliders |

| Types of Linear Guide Slider | Ball-type, roller-type, miniature sliders |

| Core Components of Linear Guide Slider | Rail, block, rolling elements, seals |

| Key Features of Linear Guide Slider | Rigidity, precision, smoothness, durability |

| How Linear Guide Slider Works | Rolling element mechanics, load distribution |

| Advantages of Linear Guide Slider | Accuracy, strength, energy efficiency |

| Applications of Linear Guide Slider | CNC, robotics, 3D printing, medical devices |

| Linear Guide Slider in CNC Machines | High-speed, vibration-free machining |

| Linear Guide Slider in Robotics | Reliable robotic arm guidance |

| Linear Guide Slider in Medical Equipment | Imaging and surgical precision |

| Miniature Linear Guide Sliders | Electronics, 3D printers, compact devices |

| Installation of Linear Guide Slider | Steps for alignment and mounting |

| Lubrication and Maintenance | Recommended greases, oils, and schedules |

| Common Problems and Troubleshooting | Noise, misalignment, wear issues |

| Linear Guide Slider vs Bushings | Key differences and performance comparison |

| Choosing the Right Linear Guide Slider | Load, speed, environment considerations |

| Customization Options | Preload levels, coatings, compact models |

| Role in Modern Automation | Smart factories and Industry 4.0 usage |

| Economic Benefits of Linear Guide Slider | ROI, reduced downtime, longevity |

| Sustainability and Environmental Impact | Energy savings, reduced waste |

| Case Studies | CNC workshops, robotics, medical industry |

| Market Trends | Global adoption and future growth |

| Frequently Asked Questions | FAQs with answers |

| Conclusion | Summary and final thoughts |

| Inbound and Outbound Link Suggestions | Suggested linking opportunities |

Introduction

In today’s world of high-speed automation and precision engineering, reliable motion systems form the backbone of progress. Every time a CNC machine carves a precise groove or a robotic arm places components on a circuit board, there is an invisible hero at work — the linear guide slider.

This seemingly simple device ensures smooth, frictionless, and accurate linear motion in machines that demand perfection. By combining rolling technology with precision-ground rails, linear guide sliders allow industries to operate faster, with higher accuracy and lower wear.

This guide explores linear guide sliders in detail — from their history and components to their applications, benefits, and future role in automation.

Linear Guide Slider

A linear guide slider is a motion component designed to move smoothly along a rail, enabling accurate linear positioning. It consists of a block (slider) that houses rolling elements such as steel balls or rollers, which reduce friction as the slider moves back and forth along the guide rail.

Linear guide sliders are essential in:

CNC machines for tool stability.

Robotics for precision arm movements.

Medical devices for safe, quiet, and smooth operation.

By eliminating most of the resistance seen in traditional bushings, linear guide sliders provide unmatched efficiency in linear motion systems.

History of Linear Guides

Linear motion systems have evolved significantly over time:

Early systems used wooden grooves and lubricated sliding bushings.

Industrial revolution introduced hardened steel bushings and shafts.

20th century brought rolling element bearings for reduced friction.

Modern linear guide sliders combine precision grinding, high-quality steel, and advanced coatings to achieve unmatched performance.

Types of Linear Guide Slider

Linear guide sliders come in several designs, each with its advantages:

Ball-Type Sliders – Smooth motion, widely used in CNC and automation.

Roller-Type Sliders – Higher load capacity and rigidity.

Miniature Sliders – Compact size, ideal for 3D printers, medical devices, and electronics.

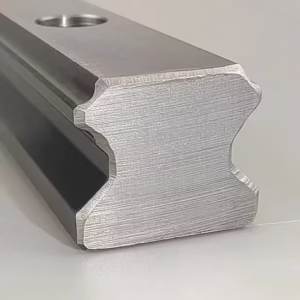

Core Components of Linear Guide Slider

The key parts of a linear guide slider include:

Guide Rail – Precision-ground steel track.

Slider (Carriage/Block) – The moving unit with rolling elements.

Rolling Elements – Balls or rollers that reduce friction.

Seals and End Caps – Prevent dust and debris from entering.

Lubrication System – Channels for grease or oil.

Each part contributes to performance, making proper installation and maintenance critical.

Key Features of Linear Guide Slider

Engineers and manufacturers rely on linear sliders because they provide:

High rigidity – Handles heavy loads.

Low friction – Ensures smooth movement.

Precision – Achieves micrometer-level accuracy.

Durability – Designed for long service life.

Quiet operation – Especially important in medical and office equipment.

How Linear Guide Slider Works

The principle is simple yet powerful: instead of sliding surfaces creating drag, the slider uses recirculating rolling elements inside the block. These balls or rollers roll along grooves in the rail and loop back in a continuous circuit.

This reduces friction dramatically, ensuring:

Higher efficiency.

Longer lifespan.

Stable and repeatable accuracy.

Advantages of Linear Guide Slider

The advantages include:

Accuracy – Vital for industries requiring precise positioning.

Smooth operation – Ensures vibration-free movement.

Durability – Designed to withstand industrial workloads.

Versatility – Works in robotics, CNC, and medical equipment.

Cost savings – Reduced wear means fewer replacements.

Applications of Linear Guide Slider

Linear guide sliders are used in:

CNC Machines – For precise tool movements.

Robotics – Smooth and accurate arm guidance.

3D Printers – High-speed, layer-by-layer accuracy.

Medical Devices – Imaging and surgical equipment.

Packaging Industry – High-speed automation lines.

Linear Guide Slider in CNC Machines

CNC machining relies heavily on sliders for tool positioning. Benefits include:

High cutting accuracy.

Reduced vibration for smoother surfaces.

Increased tool life due to stable operation.

Linear Guide Slider in Robotics

Robotics needs precise and repeatable motion. Sliders provide:

Energy-efficient guidance.

Durability under continuous use.

High accuracy for delicate tasks like assembly.

Linear Guide Slider in Medical Equipment

In medicine, precision and quiet operation are vital. Linear sliders are used in:

MRI and CT scanners.

Surgical robots.

Patient beds and imaging systems.

They ensure safety, comfort, and accurate operation.

Miniature Linear Guide Sliders

Miniature sliders are perfect for compact devices like:

Electronics assembly lines.

3D printers.

Laboratory automation.

They offer high precision in small packages.

Installation of Linear Guide Slider

Steps include:

Clean mounting surface.

Align rail precisely.

Secure bolts evenly.

Install slider carefully.

Lubricate before operation.

Lubrication and Maintenance

Proper lubrication extends service life.

Light-duty: Lubricate every 6 months.

Heavy-duty: Every 1–3 months.

Use recommended grease or oil.

Common Problems and Troubleshooting

Noise – Lack of lubrication or dirt.

Misalignment – Poor installation.

Uneven wear – Overloading or contamination.

Linear Guide Slider vs Bushings

| Feature | Linear Guide Slider | Bushings |

|---|---|---|

| Precision | High | Low |

| Friction | Low | High |

| Durability | Long | Short |

| Cost | Higher | Lower |

Choosing the Right Linear Guide Slider

Key factors include:

Load capacity.

Speed requirements.

Environmental conditions.

Size constraints.

Customization Options

Manufacturers offer:

Special coatings for corrosion resistance.

Preload levels for rigidity.

Miniature options for compact use.

High-speed designs for automation.

Role in Modern Automation

Linear sliders are vital in Industry 4.0 for:

Smart factories.

High-speed packaging.

Robotics and logistics automation.

Economic Benefits of Linear Guide Slider

Reduced downtime.

Fewer replacements.

Lower energy consumption.

Sustainability and Environmental Impact

By lowering friction and extending lifespan, linear sliders reduce waste and improve energy efficiency.

Case Studies

CNC workshop: Improved machining accuracy by 25%.

Robotics line: Enhanced production speed.

Medical company: Reduced scanner noise with miniature sliders.

Market Trends

Global adoption of linear guide sliders is increasing due to:

Rise in automation.

Expansion of CNC machining.

Growth in medical technology.

Frequently Asked Questions

What is a linear guide slider used for?

It provides smooth and accurate linear motion in CNC, robotics, and automation systems.

Are linear guide sliders durable?

Yes, they are designed for long service life with proper maintenance.

Do they require lubrication?

Yes, periodic lubrication is essential.

How are they different from bushings?

They use rolling elements for reduced friction, while bushings rely on sliding contact.

Can linear sliders handle heavy loads?

Yes, roller-type sliders are designed for high-load applications.

Are miniature linear sliders available?

Yes, they are widely used in electronics and compact devices.

Conclusion

The linear guide slider is a cornerstone of precision engineering. By providing smooth, accurate, and reliable motion, it supports industries ranging from CNC machining to robotics and medical technology.

With benefits like reduced wear, improved accuracy, and long-term cost savings, linear guide sliders remain an indispensable part of modern automation. As technology advances, their role will only expand, making them the backbone of next-generation precision systems.

Inbound and Outbound Link Suggestions

Inbound Links:

CNC Machining Basics

Robotics and Industrial Automation

Motion Control Systems Overview

Outbound Links: