Outline for the Article on Linear Rail Carriage

| Main Topic | Subtopics |

|---|---|

| Introduction to Linear Rail Carriage | What is a linear rail carriage?, Key role in automation, Brief history of linear motion systems |

| Understanding Linear Rail Carriage | Design and structure, Components of linear rail systems, Comparison with other motion guides |

| Working Principle | How linear rail carriage works, Load transfer mechanism, Contact points and rolling elements |

| Types of Linear Rail Carriages | Standard linear carriages, Flanged carriages, Wide type carriages, Miniature linear carriages |

| Materials and Construction | Common materials (steel, aluminum, ceramics), Coatings for durability, Corrosion resistance |

| Advantages of Linear Rail Carriage | High accuracy, Load distribution, Smooth motion, Low friction |

| Applications of Linear Rail Carriage | CNC machines, 3D printers, Robotics, Industrial automation, Medical devices |

| Choosing the Right Linear Rail Carriage | Load requirements, Speed and accuracy, Operating environment |

| Installation of Linear Rail Carriage | Preparation steps, Mounting process, Alignment techniques |

| Maintenance of Linear Rail Carriage | Cleaning and lubrication, Checking preload, Preventing wear and tear |

| Troubleshooting Common Issues | Misalignment problems, Noise during movement, Uneven wear |

| Linear Rail Carriage in CNC Machines | Importance in precision cutting, Reducing vibration, Extending tool life |

| Linear Rail Carriage in Robotics | Smooth axis movement, High repeatability, Compact design benefits |

| Linear Rail Carriage in 3D Printing | Improving print quality, Reducing backlash, Lightweight carriages |

| Linear Rail Carriage vs Linear Bearings | Key differences, Strengths and weaknesses, Application scenarios |

| Innovations in Linear Rail Carriage | Advanced coatings, Self-lubricating systems, Smart monitoring technology |

| Cost Considerations | Budget vs premium options, Long-term savings, When to invest in high-end models |

| Durability and Lifespan | Factors affecting lifespan, Proper usage, Warranty considerations |

| Safety Aspects | Ensuring load safety, Preventing carriage failure, Safe handling practices |

| Global Market Trends | Demand in manufacturing, Growing role in medical devices, Future outlook |

| Case Studies | Example from automotive industry, Case in aerospace, Robotics integration |

| Environmental Factors | Heat resistance, Dust and moisture, Cleanroom compatibility |

| Linear Rail Carriage for DIY Projects | Maker community usage, Affordable options, Tips for hobbyists |

| Future of Linear Rail Carriage | Role in AI-driven machines, Nanotechnology integration, Next-gen materials |

| FAQs | Six common user questions with detailed answers |

| Conclusion | Final thoughts on choosing and using linear rail carriages |

Introduction to Linear Rail Carriage

A linear rail carriage is one of the unsung heroes in the world of precision engineering. Without it, automation, robotics, and CNC machining would struggle to achieve the levels of accuracy and smoothness we often take for granted. Imagine trying to move a heavy load in a straight line, again and again, without deviation—this is where linear rail systems shine.

The technology behind them has evolved over decades, replacing older sliding mechanisms with rolling elements that drastically reduce friction. Today, linear rail carriages are indispensable in industries where precision, speed, and reliability define success.

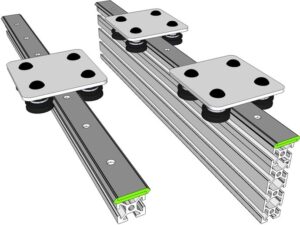

Linear Rail Carriage

At its core, a linear rail carriage consists of a block (the carriage) that slides along a rail with the help of rolling elements, usually precision steel balls or rollers. This design ensures stability while allowing smooth, linear motion under heavy loads. The accuracy of these systems can reach micrometer levels, making them ideal for industries that cannot compromise on precision.

Unlike plain sliding bearings that suffer from stick-slip effects, linear rail carriages offer predictable, consistent motion. This is why they are the backbone of CNC machines, 3D printers, and robotic arms.

Understanding Linear Rail Carriage

A linear rail carriage is more than just a moving block—it is a complex system engineered to handle forces, distribute loads, and maintain alignment. The key components include:

Rail: A hardened track providing the pathway.

Carriage (block): The moving component that carries the load.

Rolling elements: Usually steel balls or cylindrical rollers inside recirculating tracks.

End caps: Guide and recycle the rolling elements smoothly.

Preload system: Ensures stiffness and reduces vibration.

Compared to traditional bushings or sliding guides, linear carriages handle higher loads while offering minimal resistance.

Working Principle

The principle is simple yet effective: rolling elements inside the carriage move along a rail track, continuously recirculating as the carriage advances. The contact points between the rolling elements and the rail are engineered to minimize friction and distribute forces evenly.

This allows a carriage to carry loads that are both radial (vertical) and lateral (sideways), making them versatile. The design ensures minimal deflection even under stress, which is why they are common in high-precision cutting and positioning tasks.

Types of Linear Rail Carriages

The world of linear rail carriages is diverse, with each type designed to address specific needs. Selecting the correct style can dramatically impact performance.

Standard Linear Carriages: These are the most widely used, offering balanced load capacity and smooth travel for general industrial applications.

Flanged Carriages: Featuring extended mounting surfaces, they improve stability and reduce the risk of misalignment. They are excellent for heavier loads.

Wide-Type Carriages: Broader in design, these carriages distribute loads across a larger area, reducing stress on the rail and extending service life.

Miniature Carriages: Ideal for compact systems like medical devices, small robots, and precision instruments where space is at a premium.

Each design is tailored for balance between load, size, and environmental conditions. For example, a CNC router may require a wide carriage for rigidity, while a 3D printer benefits from lightweight miniatures.

Materials and Construction

The materials used in linear rail carriages play a pivotal role in durability and performance. Most carriages and rails are made from high-carbon steel, chosen for its hardness and resistance to deformation.

Other materials include:

Aluminum: Lightweight, corrosion-resistant, but less durable under heavy loads.

Ceramics: Used in specialized applications for extreme wear resistance and non-magnetic properties.

Coatings: Chrome plating or black oxide treatments help combat corrosion and extend lifespan.

Manufacturers also use heat treatment processes to harden rails and balls, ensuring they withstand high-stress conditions without losing precision.

Advantages of Linear Rail Carriage

The reason industries continue to embrace linear rail carriages lies in their multiple advantages:

High Accuracy: Precision-ground rails and carriages ensure exact positioning with minimal error.

Smooth Motion: The rolling action eliminates stick-slip effects, offering consistent travel.

Load Distribution: Forces are spread across multiple contact points, increasing load capacity.

Low Friction: Less energy wasted during motion, improving efficiency and reducing heat buildup.

Rigidity: Reduced vibration during operation ensures consistent results in machining and robotics.

These benefits make them a superior choice compared to plain bearings or belt-driven systems.

Applications of Linear Rail Carriage

The versatility of linear rail carriages makes them suitable for a vast array of industries:

CNC Machines: Provide accurate linear movement for cutting, drilling, and milling operations.

3D Printers: Enhance print quality by reducing wobble and backlash.

Robotics: Offer smooth, controlled movements essential for automation.

Industrial Automation: From packaging to assembly lines, carriages ensure reliability.

Medical Devices: Used in imaging systems and surgical robots for high-precision tasks.

The common thread in all these applications is the need for precise, reliable, and repeatable linear motion.

Choosing the Right Linear Rail Carriage

Not all carriages are created equal, and choosing the right one requires considering several factors:

Load Requirements: Heavy-duty applications demand carriages with higher load-bearing capacity.

Speed and Accuracy: High-speed systems need low-friction, rigid designs to prevent instability.

Operating Environment: Dusty or corrosive environments may require sealed or coated carriages.

Size Constraints: Compact spaces call for miniature or low-profile designs.

Budget: While premium carriages offer better durability, mid-range options balance cost and performance.

By weighing these aspects, engineers can avoid premature failures and maximize productivity.

Installation of Linear Rail Carriage

Installing a linear rail carriage requires precision and patience. Even a small misalignment can cause wear or failure.

Steps to follow:

Preparation: Clean the mounting surface to remove dust and oil.

Rail Mounting: Secure the rail to a flat, rigid base, tightening bolts gradually in sequence.

Carriage Placement: Gently slide the carriage onto the rail, ensuring rolling elements are properly seated.

Alignment: Use precision tools to check for parallelism and squareness.

Testing: Move the carriage by hand to confirm smooth, consistent travel.

A properly installed system delivers peak performance and reduces the need for early maintenance.

Maintenance of Linear Rail Carriage

Maintenance is often underestimated, yet it is vital for prolonging the life of a linear rail carriage.

Cleaning: Regularly wipe off dust and debris to prevent rolling element damage.

Lubrication: Apply the manufacturer-recommended grease or oil to reduce wear.

Preload Check: Ensure the carriage maintains proper preload to prevent vibration.

Inspection: Periodically check for uneven wear, unusual noise, or loss of accuracy.

Neglecting these simple tasks can result in premature failures and costly downtime.

Troubleshooting Common Issues

Even the best systems encounter challenges. Common issues with linear rail carriages include:

Misalignment Problems: Caused by uneven rail mounting surfaces. Fix by realigning and tightening correctly.

Noise During Movement: Often linked to poor lubrication or contamination. Clean and re-lubricate.

Uneven Wear: Typically results from overload or improper preload. Replace damaged components promptly.

Addressing these problems early ensures continued precision and avoids major breakdowns.

Linear Rail Carriage in CNC Machines

CNC machining relies heavily on the accuracy of motion systems. A linear rail carriage ensures cutting tools move smoothly, allowing for:

Precise tool paths with micrometer accuracy.

Reduced vibration during high-speed cutting.

Extended lifespan of cutting tools due to stable support.

Without linear rail systems, CNC machines would struggle with chatter, inaccuracies, and reduced efficiency.

Linear Rail Carriage in Robotics

Robotics requires high repeatability and smooth axis movement. Carriages provide:

Consistent Linear Travel: Essential for pick-and-place robots.

Compact Design: Fits well in lightweight, agile robotic arms.

Reliability: Ensures operations run continuously without breakdowns.

As robotics advances in healthcare, logistics, and manufacturing, linear rail carriages remain indispensable.

Linear Rail Carriage in 3D Printing

3D printers benefit immensely from linear carriages because:

Print Quality Improves: Carriages reduce wobbling, producing cleaner layer lines.

Reduced Backlash: Ensures parts match digital models precisely.

Lightweight Options: Miniature rails keep machines compact and efficient.

This makes them popular among both hobbyists and industrial-grade printers.

Linear Rail Carriage vs Linear Bearings

Although often confused, linear rail carriages and linear bearings differ significantly:

| Feature | Linear Rail Carriage | Linear Bearing |

|---|---|---|

| Load Capacity | Higher | Lower |

| Precision | Extremely accurate | Moderate |

| Friction | Very low | Low |

| Cost | Higher | Lower |

| Applications | CNC, robotics, automation | Light-duty sliding applications |

Carriages are the go-to choice when accuracy and load capacity cannot be compromised.

Innovations in Linear Rail Carriage

Recent innovations are pushing boundaries:

Advanced Coatings: Improve wear resistance and corrosion protection.

Self-Lubricating Systems: Reduce maintenance needs.

Smart Monitoring: Sensors track performance, predicting failures before they happen.

These innovations reflect the growing demand for smarter, longer-lasting motion systems.

Cost Considerations

While cost is always a concern, it’s crucial to see linear rail carriages as investments.

Budget Models: Sufficient for DIY or light-duty applications.

Premium Models: Offer higher load capacity, longer life, and better accuracy.

Long-Term Savings: Higher upfront cost often means reduced downtime and replacements.

Choosing wisely saves money over the life of the system.

Durability and Lifespan

Several factors influence how long a linear rail carriage lasts:

Load handling: Overloading drastically reduces service life.

Lubrication quality: Poor lubrication accelerates wear.

Environmental conditions: Dust, moisture, and extreme heat reduce efficiency.

With proper care, carriages can last tens of thousands of hours in operation.

Safety Aspects

Safety cannot be ignored. To ensure safe use:

Avoid exceeding rated load limits.

Regularly inspect for damage.

Use protective covers in dusty environments.

Follow manufacturer installation guidelines.

A small mistake in handling can lead to catastrophic failure in critical applications.

Global Market Trends

The linear rail carriage market is growing steadily due to automation demands. Industries driving growth include:

Manufacturing: CNC and robotic automation lead demand.

Medical Devices: Precision requirements for surgical and diagnostic tools.

Logistics: Robotics for warehouses and sorting facilities.

The market outlook predicts continued expansion as industries demand higher efficiency.

Case Studies

Automotive Industry: Linear carriages in robotic welding systems ensure accurate, repeatable welds.

Aerospace: Used in precision drilling of lightweight materials.

Robotics Integration: Carriages in robotic arms improve assembly line consistency.

These case studies show real-world benefits of implementing linear rail systems.

Environmental Factors

Not all environments are friendly to machinery. Carriages are designed to withstand:

Heat Resistance: Special lubricants allow operation at high temperatures.

Dust and Moisture: Sealed carriages prevent contamination.

Cleanroom Compatibility: Used in semiconductor and medical industries.

Customization ensures performance in even the harshest conditions.

Linear Rail Carriage for DIY Projects

Hobbyists and makers love using linear carriages in projects like:

DIY CNC routers.

3D printers.

Camera sliders for videography.

Affordable options are available, and with proper alignment, even DIY users can achieve professional results.

Future of Linear Rail Carriage

Looking ahead, exciting developments are emerging:

AI-Driven Machines: Smarter sensors will enable predictive maintenance.

Nanotechnology: Ultra-precise carriages for micro-manufacturing.

New Materials: Lightweight composites and ceramics will expand applications.

The future promises smarter, lighter, and more efficient motion systems.

FAQs

What is a linear rail carriage used for?

It provides precise linear movement for machines like CNC systems, 3D printers, and robots.

How long does a linear rail carriage last?

With proper maintenance, it can last tens of thousands of operating hours.

Do linear rail carriages need lubrication?

Yes, regular lubrication is crucial to prevent wear and ensure smooth motion.

What’s the difference between a linear bearing and a carriage?

Carriages handle higher loads and offer better accuracy, while bearings are for lighter-duty sliding.

Can linear rail carriages be used outdoors?

Yes, but they need corrosion-resistant coatings and protective covers.

Are linear rail carriages expensive?

They vary—basic models are affordable, but high-end ones for precision industries cost more.

Conclusion

The linear rail carriage is a cornerstone of precision engineering, bridging the gap between raw machinery and the finesse required for modern automation. Its versatility, durability, and unmatched accuracy make it invaluable across countless industries. From powering CNC machines to guiding medical robots, it embodies the blend of strength and delicacy that defines advanced technology.

For engineers, makers, and manufacturers alike, investing in a reliable linear rail carriage is not just a choice—it’s a commitment to precision, efficiency, and progress.

Inbound Link Suggestions:

Internal guide on CNC machine components

Blog post about robotics automation systems

Article on 3D printing accuracy improvements