In modern automation and mechanical design, linear rails are among the most essential components for ensuring precision, stability, and smooth motion. From CNC machines to industrial robots, linear rails guide motion with exceptional accuracy and minimal friction.

At YH Linear, we specialize in the engineering and manufacturing of high-precision linear rails that form the foundation of countless motion systems worldwide. Our designs combine technological innovation, material excellence, and strict quality control to provide unmatched performance across industries.

This comprehensive article explores everything you need to know about linear rails—their function, types, materials, benefits, installation, and maintenance—along with insights into how YH Linear has become a trusted name in precision motion systems.

Outline

| Section | Heading |

|---|---|

| 1 | Introduction to Linear Rails |

| 2 | What Are Linear Rails? |

| 3 | The Structure of Linear Rails |

| 4 | How Linear Rails Work |

| 5 | Components of a Linear Rail System |

| 6 | Importance of Linear Rails in Modern Machinery |

| 7 | Key Features of Linear Rails |

| 8 | Types of Linear Rails |

| 9 | Profiled Linear Rails |

| 10 | Round Shaft Linear Rails |

| 11 | Miniature Linear Rails |

| 12 | Heavy-Duty Linear Rails |

| 13 | Stainless Steel Linear Rails |

| 14 | Aluminum Linear Rails |

| 15 | Dual Shaft Linear Rails |

| 16 | Cross Roller Linear Rails |

| 17 | Linear Rails vs Linear Bearings |

| 18 | Advantages of Linear Rails |

| 19 | Common Applications of Linear Rails |

| 20 | How YH Linear Designs Linear Rails |

| 21 | YH Linear Manufacturing Process |

| 22 | Precision and Quality Control |

| 23 | Surface Treatments and Coatings |

| 24 | Installation and Alignment Guidelines |

| 25 | Lubrication and Maintenance |

| 26 | Troubleshooting Common Issues |

| 27 | Customization and OEM Options by YH Linear |

| 28 | Innovations in Linear Rail Design |

| 29 | Environmental Considerations |

| 30 | FAQs About Linear Rails |

| 31 | Conclusion |

Linear Rails

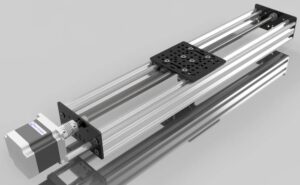

A linear rail, sometimes referred to as a linear motion guide, is a precision-engineered track that allows a linear guide block or carriage to move smoothly along a straight path.

At YH Linear, every linear rail is crafted with micro-level accuracy, ensuring smooth motion and exceptional rigidity. These rails are vital components in CNC machining centers, automated assembly lines, robotics, and many other high-precision systems.

What Are Linear Rails?

Linear rails are mechanical systems designed to guide and support linear motion while minimizing friction. They convert rotary motion into linear motion, allowing machinery to move parts or tools precisely and repeatedly.

YH Linear rails consist of a hardened rail and a carriage that uses recirculating balls or rollers to glide with minimal resistance.

The Structure of Linear Rails

A linear rail system typically includes:

The rail: A rigid, hardened steel or stainless steel track.

The block or carriage: The moving component that glides along the rail.

Rolling elements: Balls or rollers that circulate within the block for smooth movement.

Seals and caps: Protect internal components from dust and debris.

YH Linear’s rails are machined and ground to micron-level tolerances, ensuring exceptional alignment and load distribution.

How Linear Rails Work

Linear rails operate using rolling elements that circulate within a precisely machined raceway between the rail and the block.

When the carriage moves, these elements roll along the raceways, creating smooth, low-friction motion. The design supports multi-directional loads—radial, axial, and moment loads—making linear rails both strong and versatile.

Components of a Linear Rail System

| Component | Function | YH Linear Feature |

|---|---|---|

| Rail | Guides motion | High-carbon or stainless steel |

| Carriage/Block | Supports load | Optimized for smooth rolling |

| Rolling Elements | Reduce friction | Hardened steel balls or rollers |

| End Caps & Seals | Protect from debris | Advanced sealing technology |

| Lubrication System | Extends lifespan | Self-lubricating design |

Every part of a YH Linear rail is engineered for precision, durability, and ease of maintenance.

Importance of Linear Rails in Modern Machinery

Without linear rails, machines would rely on sliding friction, leading to rapid wear, heat buildup, and positional errors.

Linear rails enable:

Accurate and repeatable motion

Higher speeds and load capacities

Reduced energy consumption

Longer service life

That’s why they’re indispensable in automation, robotics, CNC machining, and medical equipment—industries where precision defines productivity.

Key Features of Linear Rails

High precision and rigidity

Low friction and smooth operation

Long operational life

Support for multi-directional loads

Easy integration and modular design

Corrosion resistance with special coatings

At YH Linear, each rail undergoes strict testing to guarantee these performance attributes.

Types of Linear Rails

Different applications require different types of linear rails. YH Linear produces several variations, including:

Profiled (square) linear rails

Round shaft rails

Miniature rails

Dual shaft systems

Cross roller rails

Aluminum and stainless steel rails

Let’s look closer at each.

Profiled Linear Rails

Profiled or square linear rails feature a rectangular cross-section with precision-ground raceways.

They are known for:

Superior stiffness

High load capacity

Excellent positional accuracy

YH Linear’s profiled rails are perfect for CNC machines, robotics, and precision automation equipment.

Round Shaft Linear Rails

Round shaft rails are simpler, using cylindrical rods instead of rectangular tracks.

They’re easier to install and better suited for applications where alignment isn’t critical.

YH Linear round shaft rails are lightweight, versatile, and cost-effective for light-load systems.

Miniature Linear Rails

For compact or lightweight equipment, miniature rails offer outstanding precision in a small footprint.

They’re used in 3D printers, medical devices, and micro-positioning equipment.

YH Linear’s MGN series miniature rails combine compactness with exceptional accuracy.

Heavy-Duty Linear Rails

Built for large-scale machinery, heavy-duty rails handle extreme loads and vibrations.

YH Linear’s heavy-duty models feature roller elements and reinforced raceways for industrial-grade performance.

Stainless Steel Linear Rails

Stainless steel rails are corrosion-resistant and ideal for cleanroom environments.

They’re widely used in food processing, medical equipment, and marine applications.

YH Linear ensures each stainless rail maintains its precision under harsh conditions.

Aluminum Linear Rails

Lightweight yet strong, aluminum rails are perfect for applications that demand speed and efficiency.

They reduce inertia and are resistant to rust and corrosion, ideal for robotics and automated systems.

Dual Shaft Linear Rails

Dual shaft designs use two parallel rods for improved load stability.

They are often found in gantry systems and multi-axis assemblies, where balance is crucial.

YH Linear dual shaft rails ensure perfect parallelism and rigidity for long-travel systems.

Cross Roller Linear Rails

Using rollers arranged in an alternating cross pattern, these rails offer ultra-smooth motion with higher rigidity than ball-based types.

YH Linear cross roller rails are popular in optical and measuring instruments.

Linear Rails vs Linear Bearings

| Aspect | Linear Rail | Linear Bearing |

|---|---|---|

| Structure | Rail + carriage | Shaft + bushing |

| Precision | Very high | Moderate |

| Load Capacity | Higher | Lower |

| Maintenance | Minimal | Moderate |

| Applications | CNC, robotics | Light automation, printing |

YH Linear designs both, depending on your precision and cost requirements.

Advantages of Linear Rails

High accuracy and repeatability

Support for heavy and multi-directional loads

Compact structure

Easy installation and maintenance

Reduced vibration and noise

YH Linear rails are tested to ensure millions of cycles of smooth, reliable motion.

Common Applications of Linear Rails

CNC machining centers

Industrial robotics

Semiconductor equipment

3D printers

Packaging machinery

Medical imaging devices

Automation lines

YH Linear rails are designed for precision motion in all these demanding environments.

How YH Linear Designs Linear Rails

Our design philosophy combines innovation, efficiency, and endurance.

Each rail is:

CNC-machined for precision

Heat-treated for hardness

Ground for smoothness

Inspected for dimensional accuracy

This ensures every YH Linear product performs flawlessly from the first use to the last.

YH Linear Manufacturing Process

YH Linear’s advanced production includes:

CNC milling and grinding

Automated polishing and hardening

Laser inspection for straightness

Final assembly in controlled environments

Each rail passes 100% quality verification before shipping.

Precision and Quality Control

We maintain ISO 9001-certified processes for:

Dimensional tolerance testing

Load and life-cycle testing

Corrosion and vibration resistance tests

YH Linear’s strict standards guarantee consistent excellence across every batch.

Surface Treatments and Coatings

YH Linear offers various coatings for durability:

Black oxide: Prevents corrosion

Nickel plating: Enhances wear resistance

Hard chrome finish: Extends lifespan

These treatments keep our rails operational even in harsh or wet conditions.

Installation and Alignment Guidelines

Clean surfaces and remove debris.

Align rails precisely with mounting holes.

Apply uniform torque on bolts.

Move the carriage manually to test smoothness.

YH Linear provides detailed guides to ensure correct assembly and maximum longevity.

Lubrication and Maintenance

Proper lubrication reduces friction and extends life.

Use YH Linear-approved lubricants and apply grease regularly depending on the environment and usage.

For cleanrooms, we recommend dry or low-vapor lubricants.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Noise | Lack of lubrication | Reapply grease |

| Vibration | Misalignment | Realign rail |

| Rust | Contamination | Clean and recoat |

| Sticking | Debris | Remove and clean |

YH Linear’s technical team provides guidance for all operational concerns.

Customization and OEM Options by YH Linear

We support:

Custom lengths and hole spacing

Special coatings and materials

OEM branding and labeling

Tailored preload settings

Our OEM program serves manufacturers seeking custom motion solutions built to specification.

Innovations in Linear Rail Design

YH Linear continues to innovate with:

Smart lubrication systems

Corrosion-proof coatings

Lightweight hybrid materials

Digital wear tracking sensors

We aim to make linear motion smarter, faster, and longer-lasting.

Environmental Considerations

All YH Linear products are RoHS compliant and manufactured with eco-friendly processes.

We reduce waste through precision machining and optimized energy use during production.

FAQs About Linear Rails

What is the function of a linear rail?

It guides precise, low-friction motion in a straight path.

Are YH Linear rails interchangeable with other brands?

We recommend pairing YH Linear rails and blocks for optimal performance.

How long do linear rails last?

With correct maintenance, YH Linear rails last millions of cycles or several years.

Do they require lubrication?

Yes, periodic lubrication ensures long-term smooth operation.

Can YH Linear customize rail sizes?

Absolutely. Custom sizes, coatings, and preload options are available.

Conclusion

The linear rail is a cornerstone of modern automation, driving innovation and precision in countless industries. From compact miniature rails to industrial heavy-duty systems, every type serves a vital role in ensuring stability, accuracy, and repeatability.

At YH Linear, we’re proud to design and manufacture world-class linear rails that meet the highest standards of performance and reliability. Whether you’re building a CNC system, robotic assembly, or precision laboratory equipment, our linear motion technology is your trusted foundation for success.

Inbound Link Suggestions:

Link to: “Types of Linear Rails”

Link to: “Linear Guide Block”

Outbound Link Suggestions:

Link to: YH Linear Official Website

Link to: ISO 9001 Quality Standards