Introduction to Linear Slide Rail Systems

Fundamental Principles of Linear Slide Rail Systems

The Basic Motion Principle

Guidance Mechanism: A rigid rail or track that defines the linear path of motion Moving Component: A carriage, block, or slider that travels along the rail Support Structure: Components that maintain proper alignment and load distribution Motion Transfer: Connection to a driving mechanism (manual, motorized, or actuated)

The rail provides a precision-machined reference surfacethat maintains straightness and dimensional stability The carriage contains precision bearings or rollersthat facilitate smooth movement along the rail The interaction between rail and carriage minimizes frictionwhile distributing loads appropriately The overall system maintains rigidity and stabilityeven under varying load conditions

Motion Control Characteristics

Precision: The ability to follow a defined path with minimal deviation Repeatability: The consistency with which the system returns to the same position Rigidity: The system’s resistance to deflection under load Smoothness: The quality of motion without jerks or vibrations Load Capacity: The maximum force the system can support in various directions

Key Components of Linear Slide Rail Systems

1. Guide Rails (Tracks)

Precision-machined raceways(ground to exacting tolerances) Various cross-sectional profiles(square, profiled, or specialized) Different materials(typically hardened steel, sometimes stainless or ceramic-coated) Multiple mounting options(flanged, base-mounted, etc.)

High rigidityto maintain precision under load Excellent surface finishfor reduced friction Thermal stabilityto minimize expansion effects Load distribution featuresfor optimized performance

2. Carriages (Blocks/Sliders)

Precision-machined pocketsfor rolling elements or sliding mechanisms Various sizes and load capacities Different mounting configurations(for attachments and payloads) Multiple roller or slider arrangements(for different load directions)

Optimized internal geometryfor smooth motion High-quality sealing systemsfor contamination protection Precision-matched componentsfor consistent performance Various preload optionsfor performance tuning

3. Rolling Elements or Sliding Mechanisms

Cylindrical rollers(for high load capacity) Ball bearings(for lower friction and higher speeds) Needle rollers(for compact applications) Cam follower rollers(for specialized applications)

Recirculating ball systems(for smooth motion with moderate loads) Plain sliding surfaces(for simple, low-cost applications) Hydrostatic or aerostatic bearings(for ultra-high precision applications)

4. Retainers (Cages) – For Rolling Element Systems

Prevent roller contact(reducing friction and wear) Maintain proper load distribution Various materials(steel, brass, polymer, etc.) Different designs(for different roller configurations)

Minimal frictionto enhance efficiency Durabilityto withstand operational conditions Proper clearancefor reliable operation Appropriate material selectionfor the application

5. Preload Mechanisms

Zero clearance or slight preloadfor optimal performance Different preload levels(light, medium, heavy) Affects stiffness, accuracy, and friction Customizable for specific application requirements

Improved rigidityfor precise positioning Reduced deflectionunder load Enhanced accuracy and repeatability Optimized performance characteristics

Types of Linear Slide Rail Systems

1. Ball Bearing Slide Systems

Low frictionfor high-speed applications Good precisionfor general manufacturing Moderate load capacity Relatively compact design

Single-axis ball slides(for linear motion along one axis) Dual-axis or crossed slides(for complex motion patterns) Compact ball slides(for space-constrained applications) Precision ball slides(for high-accuracy requirements)

2. Roller Bearing Slide Systems

Higher load capacitythan ball systems Greater rigidityunder load Good for heavier applications Slightly higher friction than ball systems

Cylindrical roller slides(for standard heavy-duty applications) Needle roller slides(for compact, high-load applications) Tapered roller slides(for combined load applications) Precision roller slides(for high-accuracy heavy-duty applications)

3. Plain Bearing Slide Systems

Simple, low-cost design No rolling elements to maintain Can handle some misalignment Generally lower precision and higher friction

Bronze or polymer plain bearings(for general applications) Hydrostatic plain bearings(for ultra-high precision) Self-lubricating plain bearings(for maintenance-free operation) Sleeve or flange plain bearings(for specific mounting configurations)

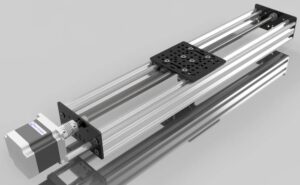

4. Linear Guide Rail Systems

High rigidity and precision Excellent load capacity Designed for industrial automation Modular system components

Square rail linear guides(for high load capacity and rigidity) Profile rail linear guides(for various load configurations) Miniature linear guides(for small, precise applications) Heavy-duty linear guides(for extreme loads)

5. Crossed Roller Slide Systems

Extremely high rigidityand precision Equal load capacity in all directions Compact designwith high performance Excellent for precision positioning

Precision stages and tables Robot joints and wrists Precision measuring equipment High-precision automation

Materials and Construction

1. Rail and Carriage Materials

Hardened alloy steel(most common, offering excellent wear resistance) Stainless steel(for corrosive environments) Ceramic-coated or treated surfaces(for specialized applications) Precision heat treatment(for optimal hardness and durability)

2. Rolling Element Materials

Chrome steel (AISI 52100)(most common, offering excellent hardness and wear resistance) Stainless steel(for corrosive or clean environments) Ceramic (silicon nitride)(for high-speed, high-temperature, or non-magnetic applications) Specialized alloys(for specific performance requirements)

3. Retainer Materials

Steel(for strength and durability) Brass(for good wear resistance and quiet operation) Polymer/plastic(for low-friction, lightweight, or high-temperature applications) Composite materials(for specialized applications)

4. Surface Treatments and Coatings

Hard chrome plating(for enhanced wear resistance) Nitriding or other surface hardening processes(for improved durability) Corrosion-resistant coatings(for harsh environments) Dry lubricant coatings(for maintenance-free operation)

Key Performance Characteristics

1. Load Capacity

Dynamic load capacity(maximum load during motion) Static load capacity(maximum load without motion) Moment load capacity(resistance to tipping forces) Load ratingsvary widely based on size, design, and materials

2. Precision and Tolerance

Accuracy grades(from standard to micron-level precision) Repeatability(ability to return to the same position) Straightness, flatness, and parallelismof components ABEC or similar ratingsfor bearing precision

3. Speed and Acceleration

Maximum allowable speed(based on size, lubrication, and design) Acceleration capabilities(for dynamic applications) DN factor(bearing bore diameter × rpm) indicating speed limitations Critical speed considerationsfor long travel applications

4. Stiffness and Rigidity

System stiffness(resistance to deflection under load) Preload effectson rigidity Rail and carriage designaffecting overall stiffness Mounting considerationsimpacting system rigidity

5. Life Expectancy

L10 bearing life(the number of revolutions at which 90% of bearings will still be operational) Travel lifeestimates based on load and speed Maintenance intervalsand relubrication requirements Environmental factorsaffecting component life

Applications of Linear Slide Rail Systems

1. Industrial Automation and Manufacturing

CNC machinesfor precision metalworking Automated assembly linesfor various components Material handling equipmentfor production processes Roboticsfor precise positioning tasks

2. Machine Tools

Milling machinesand machining centers Grinding machinesand lapping equipment Drilling and tapping machines EDM (electrical discharge machining) equipment

3. Precision Measurement and Inspection

Coordinate measuring machines (CMMs) Optical inspection equipment Metrology systems Gauging and inspection fixtures

4. Medical and Laboratory Equipment

Diagnostic equipmentwith precise positioning requirements Laboratory automation systems Medical imaging equipment Surgical robots and assistive devices

5. Semiconductor and Electronics Manufacturing

Wafer handling equipment Pick-and-place machines Precision dispensing systems Cleanroom automation equipment

Selection Criteria for Linear Slide Rail Systems

1. Load Requirements

Magnitude and direction of loads(radial, axial, or moment loads) Static vs. dynamic loading conditions Load distribution(even or concentrated) Expected shock or impact loads

2. Precision and Accuracy Needs

Required positioning accuracy(microns to millimeters) Repeatability requirements Application tolerance specifications System stiffness needs

3. Travel Distance and Speed Requirements

Required travel length Maximum operational velocity Acceleration/deceleration rates Duty cycle(percentage of time in motion)

4. Environmental Conditions

Temperature rangeand thermal considerations Exposure to contaminants(dust, moisture, chemicals) Corrosive or hygienic environment requirements Vacuum or special atmospheric conditions

5. Maintenance and Service Life

Lubrication requirementsand maintenance intervals Expected service lifeand operating hours Environmental sealing needs Replacement and spare parts availability

Installation and Alignment Best Practices

1. Pre-Installation Preparation

Verify component compatibility(ensure all parts match specifications) Inspect components for damage(check for shipping or handling issues) Prepare the installation area(clean, level, and accessible workspace) Gather proper tools and equipment(including precision measuring instruments)

2. Rail Installation

Mount rails parallel(within specified tolerance, typically 0.02-0.05 mm/m) Maintain correct spacing(based on carriage design and load requirements) Use appropriate fasteners(with proper torque specifications) Follow manufacturer’s alignment procedures(often using gauge blocks or laser alignment tools)

3. Carriage and Drive System Installation

Mount carriages securely(following manufacturer’s guidelines) Install drive system components(belts, screws, motors) with proper alignment Adjust belt tension or screw pre-load(to specified values) Verify free movement(without binding or excessive friction)

4. Final Alignment and Testing

Systematic alignment verification(checking all axes and planes) Initial movement testing(verifying smooth operation at low speed) Load testing(gradually applying operational loads) Performance validation(checking against specified accuracy and repeatability)

Maintenance and Troubleshooting

1. Routine Maintenance Procedures

Lubrication(applying appropriate lubricants at specified intervals) Inspection(checking for wear, damage, or contamination) Cleaning(removing debris and contaminants) Tightening(checking and adjusting fastener torques) Alignment verification(periodic checks for maintaining precision)

2. Common Maintenance Tasks

Roller or bearing inspection(checking for wear, damage, or contamination) Seal and retainer inspection(checking for wear or damage) Fastener inspection(checking for proper torque and tightness) Carriage and rail inspection(checking for wear, damage, or misalignment) Lubrication system maintenance(checking reservoirs, lines, and delivery)

3. Troubleshooting Common Issues

Excessive noise or vibration(may indicate misalignment, wear, or improper lubrication) Binding or erratic movement(could result from contamination, misalignment, or worn components) Positioning inaccuracies(often related to backlash, wear, or sensor issues) Premature wear(typically caused by contamination, overload, or improper lubrication) Overheating(may indicate excessive friction, inadequate lubrication, or drive issues)

Future Trends in Linear Slide Rail Systems

1. Smart and Connected Systems

Integrated sensorsfor monitoring load, temperature, and vibration Predictive maintenancecapabilities Digital twinsfor simulation and optimization Remote monitoring and diagnostics

2. High-Precision and Nanopositioning Technologies

Sub-micron positioning capabilities Advanced materialsfor enhanced performance Thermal compensation systems Vacuum and cleanroom compatible designs

3. Energy Efficiency and Sustainability

Low-friction materials and designs Regenerative braking concepts Lightweight components Eco-friendly lubricants and materials

4. Integrated Motion Solutions

Pre-configured linear motion modules Modular designs for flexible configuration Customized solutions for specific applications Simplified maintenance and installation

5. Advanced Materials and Manufacturing Techniques

New material developmentsfor enhanced performance Additive manufacturingfor specialized components Precision fabrication techniques Surface treatment innovations

Conclusion

wang, tingting