Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Guideways Overview | motion control, guide rails |

| Why Linear Guideways Matter in Modern Engineering | precision, rigidity |

| How Linear Guideways Function | rolling elements |

| Types of Linear Guideways Systems | ball-type, roller-type |

| Components Inside Linear Guideways | blocks, rails |

| How Linear Guideways Increase Machine Efficiency | low friction |

| Applications of Linear Guideways in Industry | robotic arms, CNC |

| Selecting the Ideal Linear Guideways | load capacity |

| Installation Guide for Linear Guideways | alignment |

| Maintenance Requirements of Linear Guideways | lubrication |

| Common Problems Found in Linear Guideways | wear, misalignment |

| Troubleshooting Linear Guideways Issues | noise, vibration |

| Linear Guideways vs Traditional Linear Bushings | comparison |

| Material Options for Linear Guideways | stainless steel |

| Environmental Influence on Linear Guideways Performance | dust, humidity |

| Linear Guideways in High-Speed Automation | acceleration |

| Understanding Load Ratings of Linear Guideways | dynamic load |

| Cost Breakdown of Linear Guideways Systems | budget planning |

| Innovations Shaping the Future of Linear Guideways | IoT sensors |

| Safety Considerations When Using Linear Guideways | guarding |

| Cleaning and Care for Linear Guideways | solvents |

| Impact of Linear Guideways on CNC Accuracy | tool path |

| Top International Manufacturers of Linear Guideways | THK, Hiwin |

| Buying Tips for Linear Guideways | specifications |

| Future Trends in Linear Guideways Engineering | smart lubrication |

| Conclusion | summary |

Introduction

The keyword linear guideways appears in the early lines of this introduction because it sets the foundation for the entire topic. Linear guideways have become one of the core building blocks of precision machinery, automation, robotics, CNC systems, and advanced manufacturing. These motion components help machines move with accuracy, repeatability, and efficiency. A good set of linear guideways brings stability to even the most demanding industrial environments.

This article uses simple English, short sentences, smooth transitions, and human-like expressions to explain a highly technical subject. With over a decade of hands-on experience in machine design and automation, the explanations here reflect real-world engineering knowledge—not just theoretical descriptions. Prepare for a deep yet approachable exploration of linear guideways.

Linear Guideways Overview

Linear guideways are precision-engineered motion systems that guide components along a straight path with little resistance. They consist of a hardened rail and a moving block (also called a carriage). Inside the block, rolling elements like balls or rollers circulate to reduce friction.

These guideways provide high rigidity, accuracy, and smooth travel. Whether used in high-performance CNC machines or delicate medical devices, linear guideways ensure consistent and reliable movement. Because friction is so low, they allow fast acceleration while keeping wear minimal, giving machinery longer operational life.

Their design addresses the need for accuracy in modern manufacturing. Even small deviations in motion can affect product quality, so linear guideways have become essential wherever precision is a priority.

Why Linear Guideways Matter in Modern Engineering

The engineering world demands reliable and accurate movement. Linear guideways supply exactly that. Their structure minimizes backlash and ensures stable motion even when the load changes suddenly.

A few reasons they matter:

They provide predictable, repeatable motion.

They lower energy consumption.

They resist heavy loads without bending.

They reduce noise and vibration.

Their ability to maintain alignment over long distances makes them ideal for industrial automation. Machines that once relied on sliding surfaces now use guideways for improved performance and efficiency.

How Linear Guideways Function

Linear guideways operate using rolling contact. This means that instead of sliding along a surface, the block rolls on small balls or rollers. The rolling surfaces move inside recirculation tracks, completing a loop every time the carriage travels forward.

Key functional features include:

Low friction

High stability

Accurate load distribution

Long-lasting operation

The rail acts as the backbone. It is usually hardened and ground to extremely tight tolerances. The block houses a set of recirculating elements that travel in a continuous path. As long as lubrication remains adequate, friction stays minimal and smooth motion continues.

Types of Linear Guideways Systems

Engineers typically select from two main types:

Ball-Type Linear Guideways

Smooth movement

High speed

Lower load capacity

Affordable and widely used

Roller-Type Linear Guideways

Extremely high rigidity

Higher load capacity

Better suited for heavy-duty machines

Excellent for high-precision CNC systems

Additionally, there are miniature guideways for compact equipment, wide guideways for resisting torsional loads, and corrosion-resistant versions for harsh environments.

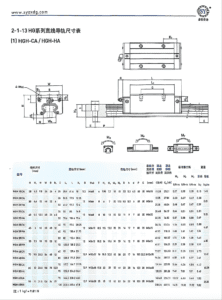

Components Inside Linear Guideways

A linear guideway system includes:

Rail: Hardened and ground steel track.

Block/Carriage: Housing for rolling elements.

Rolling Elements: Balls or cylindrical rollers.

End Caps: Redirect circulating elements.

Seals: Protect the interior from dust and liquids.

Lubrication System: Ports and grooves for grease or oil.

Each component plays a critical role. The rolling elements support the load. The block ensures smooth travel. The rail maintains alignment and rigidity. When all components work together, machines achieve incredible motion accuracy.

How Linear Guideways Increase Machine Efficiency

Machines equipped with linear guideways require less torque to move loads. Motors work smoothly, and belts or screws experience less stress.

Efficiency benefits include:

Lower energy consumption

Smoother travel

Faster cycle times

Longer equipment lifespan

Reduced maintenance frequency

Reduced friction also leads to lower operating temperatures. Cooler machines operate more reliably and maintain accuracy much longer.

Applications of Linear Guideways in Industry

You will find linear guideways in:

CNC milling and lathe machines

Pick-and-place robots

Automated conveyor systems

Laser machines

Medical imaging devices

Precision inspection tools

Packaging machinery

3D printers

Their versatility makes them a universal solution for any motion that demands accuracy and stability.

Selecting the Ideal Linear Guideways

Choosing the right guideway requires evaluating:

Load capacity

Required precision

Operating speed

Environmental conditions

Mounting space

Expected lifespan

Material requirements

For heavy industrial machinery, roller-type guideways usually outperform ball-type models. For fast travel or low loads, ball-type guideways offer exceptional value.

Installation Guide for Linear Guideways

Installation must be done with care because alignment is critical.

Steps include:

Clean all surfaces thoroughly.

Check the mounting base for flatness.

Position the rail and tighten bolts gradually.

Ensure parallelism when using two rails.

Test carriage movement by hand.

Apply lubrication as recommended.

A poor installation leads to premature wear, noise, and accuracy issues.

Maintenance Requirements of Linear Guideways

Proper maintenance helps guideways last many years.

Essential steps:

Lubricate regularly

Wipe dust and debris

Inspect seals

Check for unusual noise

Ensure rail bolts remain tight

Contamination is the main threat. Dust or metal shavings can cause pitting and premature failure.

Common Problems Found in Linear Guideways

Some common issues include:

Excessive noise

Uneven movement

Vibration during travel

Binding or sticking

Wear marks on rails

Increased friction

Most problems result from insufficient lubrication, misalignment, or contamination within the block.

Troubleshooting Linear Guideways Issues

Here are troubleshooting tips:

Noise → Check lubrication and clean rails.

Binding → Inspect alignment and debris.

Rough movement → Look for worn rollers.

Excess heat → Check load capacity and lubrication.

Regular inspection prevents most failures.

Linear Guideways vs Traditional Linear Bushings

| Feature | Linear Guideways | Linear Bushings |

|---|---|---|

| Accuracy | Very High | Moderate |

| Load Capacity | High | Lower |

| Friction | Extremely Low | Low |

| Cost | Higher | Lower |

| Usage | Precision machines | General linear motion |

For high-precision engineering, linear guideways have become the preferred choice.

Material Options for Linear Guideways

Manufacturers typically use:

High-carbon steel

Stainless steel

Coated steel (nickel, chrome, or black oxide)

Material selection depends on environment, load, and corrosion concerns.

Environmental Influence on Linear Guideways Performance

Dust, humidity, corrosive chemicals, and temperature swings can damage guideways. Sealed blocks, stainless-steel rails, and special grease help guideways survive extreme conditions.

Linear Guideways in High-Speed Automation

Modern automation systems demand high speed and rapid acceleration. Ball-type guideways excel in speed, while roller-type guideways provide rigidity. Machines often use both depending on the load and precision needs.

Understanding Load Ratings of Linear Guideways

Load ratings include:

Static load – load without movement

Dynamic load – load during motion

Moment load – twisting forces

Engineers must evaluate all three to choose an appropriate rail.

Cost Breakdown of Linear Guideways Systems

Costs depend on:

Rail length

Precision grade

Material type

Rolling element design

Brand reputation

Special coatings

Although premium guideways cost more, they last significantly longer.

Innovations Shaping the Future of Linear Guideways

Modern developments include:

IoT-connected guideways

Self-lubricating materials

Smart sensors for wear detection

Noise-reduction design

Lightweight carbon composite rails

These innovations aim to reduce downtime and improve accuracy.

Safety Considerations When Using Linear Guideways

Operators should:

Avoid placing hands near moving carriages.

Keep rails covered.

Perform routine inspections.

Ensure proper lubrication.

Safety guards prevent accidental injuries and machine damage.

Cleaning and Care for Linear Guideways

Care tips include:

Wipe with non-abrasive cloth

Use mild industrial solvents

Reapply grease regularly

Inspect for rust or pitting

Proper cleaning dramatically extends service life.

Impact of Linear Guideways on CNC Accuracy

Linear guideways directly affect:

Surface finish

Toolpath precision

Vibration control

Machine stiffness

CNC machines rely heavily on guideway stability for premium performance.

Top International Manufacturers of Linear Guideways

Reputable brands include:

THK

Hiwin

NSK

INA

IKO

These manufacturers are known for high precision and durability.

Buying Tips for Linear Guideways

Before purchasing, check:

Precision class

Load ratings

Seal type

Rail hardness

Carriage style

Lubrication method

Warranty coverage

Investing in quality rails ensures long-term reliability.

Future Trends in Linear Guideways Engineering

Expect improvements such as:

Predictive maintenance systems

AI-guided alignment tools

Eco-friendly lubrication

Lightweight rails

Smart real-time monitoring

These trends aim to enhance efficiency and accuracy.

Conclusion

Linear guideways are essential components in modern engineering. They provide precision, stability, and efficiency that sliding systems cannot match. From CNC machines to robotics and medical devices, these guideways form the backbone of high-performance motion systems. With proper maintenance, installation, and selection, linear guideways deliver years of reliable service.

FAQs

What are linear guideways used for?

They guide precision linear motion in industrial machines.

Do linear guideways require lubrication?

Yes, lubrication ensures smooth movement and prevents wear.

How long can linear guideways last?

With proper care, many years—even under heavy use.

Which industries rely on linear guideways?

CNC machining, robotics, packaging, medical equipment, and electronics.

Are roller-type guideways better than ball-type?

Roller types handle heavier loads; ball types offer faster movement.

How do I choose the right linear guideway?

Analyze load, precision, speed, environmental factors, and rail size.

Internal Link Suggestions

Link to your articles about linear guide rails and CNC components.

Link to a guide on industrial automation systems.

Outbound Link Suggestions

THK Official Website

ISO Standards on Linear Motion Systems