Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Slide Guide | linear guide system, motion technology |

| Understanding the Basics of Linear Slide Guide | linear bearing, slide rail |

| Components of a Linear Slide Guide | guide rail, carriage, rolling elements |

| Working Principle of Linear Slide Guide | motion accuracy, rolling friction |

| Advantages of Using Linear Slide Guides | precision, load capacity, low noise |

| Different Types of Linear Slide Guides | ball guide, roller guide, cross roller |

| Linear Slide Guide vs Linear Bushings | comparison, design differences |

| Linear Slide Guide Materials and Coatings | stainless steel, hardened steel |

| Selecting the Right Linear Slide Guide | load, speed, precision requirements |

| Applications of Linear Slide Guides | CNC, automation, robotics |

| Maintenance Tips for Linear Slide Guides | lubrication, cleaning |

| Common Problems and Troubleshooting | wear, vibration, noise |

| Installation Guidelines | alignment, mounting |

| Miniature Linear Slide Guides | compact motion systems |

| Heavy-Duty Linear Slide Guides | industrial automation |

| Innovations in Linear Slide Guide Design | self-lubricating, smart monitoring |

| YH Linear: Trusted Linear Slide Guide Manufacturer | OEM, custom linear guides |

| Environmental Considerations | corrosion protection, energy efficiency |

| FAQs | maintenance, lifespan, interchangeability |

| Conclusion | durability, precision, performance |

Introduction to Linear Slide Guide

In the world of industrial automation and precision engineering, the linear slide guide plays a pivotal role. It ensures smooth, accurate, and repeatable linear motion for machines in manufacturing, CNC machining, and robotics.

The linear slide guide transforms sliding motion into rolling motion, drastically reducing friction and wear. This transformation enables machines to maintain high precision, even under heavy loads and high-speed conditions. Understanding its structure, operation, and selection criteria can help engineers design more efficient, reliable systems.

Understanding the Basics of Linear Slide Guide

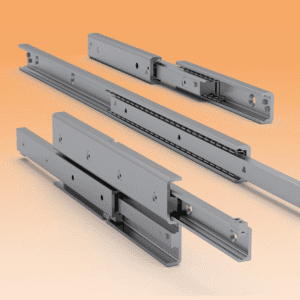

A linear slide guide—also called a linear guideway or linear motion guide—is a system that allows a load to move linearly along a rail with minimal friction.

It typically consists of:

Guide Rail: The track along which the motion occurs.

Carriage (or Block): The moving component that supports and carries the load.

Rolling Elements: Steel balls or cylindrical rollers that facilitate motion.

By converting sliding friction into rolling motion, a linear slide guide provides superior accuracy, longevity, and performance compared to traditional bushings or plain bearings.

Components of a Linear Slide Guide

Every linear slide guide has three key components working in harmony:

Guide Rail: Made of hardened steel, precisely ground to provide straight motion.

Carriage or Block: Houses the rolling elements and interfaces with the rail.

Rolling Elements: Usually ball bearings or rollers that recirculate within the block to enable continuous motion.

Some guides include end seals, lubrication ports, and preload adjustments for enhanced performance and maintenance.

Working Principle of Linear Slide Guide

The linear slide guide operates on a simple yet powerful concept: the conversion of sliding friction into rolling friction.

When the carriage moves along the rail, the rolling elements inside the block roll between the rail and carriage surfaces. As these elements circulate, they provide:

Consistent linear motion without slippage.

Low friction coefficient compared to plain sliding surfaces.

Stable motion even at high speeds and loads.

This design ensures long life, reduced energy consumption, and precision in motion-critical applications.

Advantages of Using Linear Slide Guides

Using a linear slide guide offers several key benefits:

High Precision: Maintains tight tolerances and repeatable positioning.

Low Friction: Reduces energy loss and heat buildup.

Long Service Life: Durable design withstands heavy and continuous use.

Compact Structure: Efficient use of space in machines.

Easy Maintenance: Many models are self-lubricating and sealed.

Quiet Operation: Smooth rolling minimizes vibration and noise.

These qualities make linear slide guides indispensable in modern engineering and automation.

Different Types of Linear Slide Guides

There are several types of linear slide guides, each suited for specific applications:

Ball-Type Linear Slide Guide: Uses recirculating ball bearings for high-speed, low-friction movement.

Roller-Type Linear Slide Guide: Uses cylindrical rollers for increased rigidity and load capacity.

Cross Roller Slide Guide: Offers extremely smooth, precise movement using perpendicularly arranged rollers.

Miniature Linear Slide Guide: Compact design ideal for small, precision devices.

Heavy-Duty Linear Slide Guide: Reinforced structure for high-load applications.

Each type varies in cost, precision, and load-bearing capability.

Linear Slide Guide vs Linear Bushings

While both provide linear motion, linear slide guides outperform linear bushings in many aspects.

| Feature | Linear Slide Guide | Linear Bushing |

|---|---|---|

| Friction | Very low | Moderate |

| Load Capacity | High | Medium |

| Accuracy | Excellent | Average |

| Rigidity | High | Low |

| Cost | Higher | Lower |

| Ideal For | CNC, robotics | Light automation |

For precision-critical systems, linear slide guides are the preferred choice.

Linear Slide Guide Materials and Coatings

Materials play a vital role in the performance of a linear slide guide.

Hardened Bearing Steel (SUJ2): Common for standard environments.

Stainless Steel: Ideal for cleanrooms, medical equipment, and corrosive settings.

Aluminum Rails: Used for lightweight applications.

Protective Coatings: Chrome or nickel plating improves corrosion and wear resistance.

Proper material selection ensures durability under demanding conditions.

Selecting the Right Linear Slide Guide

Choosing the right linear slide guide involves evaluating:

Load Capacity: The total static and dynamic forces acting on the system.

Precision Grade: Determines the level of accuracy needed.

Speed and Acceleration: Affects rolling element design.

Environment: Dust, humidity, and temperature influence materials and lubrication.

Mounting Orientation: Vertical, horizontal, or inverted setups affect load distribution.

Consulting an expert supplier like YH Linear ensures a solution tailored to your exact requirements.

Applications of Linear Slide Guides

The linear slide guide is widely used in various high-precision and automation fields:

CNC Machining Centers – High rigidity for cutting accuracy.

3D Printers – Smooth, stable motion for consistent prints.

Robotic Arms – Repeatable motion paths with minimal deviation.

Medical Devices – Clean and precise operation in sterile environments.

Packaging Machinery – Fast, reliable linear motion for product handling.

Its versatility makes it a foundation of precision automation systems.

Maintenance Tips for Linear Slide Guides

To extend the lifespan of a linear slide guide:

Keep rails clean and free from dust or debris.

Apply manufacturer-recommended lubricants regularly.

Check for preload adjustments and tightness.

Inspect end seals and wipers for wear.

Store spare guides in dry, temperature-controlled environments.

Preventive maintenance ensures consistent accuracy and smooth performance.

Common Problems and Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Vibration or Noise | Misalignment or contamination | Clean and realign |

| Rough Motion | Lack of lubrication | Reapply grease or oil |

| Corrosion | Humidity or chemical exposure | Use stainless steel guides |

| Wear Marks | Overloading | Reduce load or use heavy-duty model |

Quick diagnosis and timely care can prevent costly downtime.

Installation Guidelines

Proper installation ensures the linear slide guide performs as designed:

Ensure the mounting surface is flat and clean.

Align the rail precisely to avoid uneven stress.

Use torque-controlled tightening for screws.

Avoid over-preloading the carriage.

Test smoothness before full operation.

Accurate installation is crucial for achieving top performance and extended service life.

Miniature Linear Slide Guides

Miniature linear slide guides are compact, lightweight versions ideal for delicate applications.

Features:

Extremely smooth, precise motion.

Compact design for limited spaces.

Corrosion-resistant materials.

Applications:

Optical instruments

Laboratory automation

Semiconductor devices

Their precision makes them indispensable in modern micro-engineering.

Heavy-Duty Linear Slide Guides

Designed for strength and stability, heavy-duty linear slide guides are perfect for industrial and manufacturing systems.

Features:

Thick rails and reinforced blocks.

Excellent shock absorption.

Long service life under continuous load.

Applications:

CNC milling centers

Press machines

Injection molding systems

Durability and rigidity define this category.

Innovations in Linear Slide Guide Design

Recent innovations are transforming linear slide guides:

Smart Sensors: Monitor wear and temperature in real time.

Self-Lubricating Blocks: Reduce maintenance intervals.

Lightweight Alloys: Improve energy efficiency.

Low-Noise Technology: Enhances machine comfort and precision.

These advancements are shaping the future of intelligent motion systems.

YH Linear: Trusted Linear Slide Guide Manufacturer

YH Linear is a global leader in manufacturing linear slide guides designed for precision, reliability, and durability.

Why YH Linear?

ISO-certified production standards.

OEM/ODM customization available.

Advanced manufacturing technology.

Global distribution and technical support.

Whether it’s for CNC machinery, robotics, or automation, YH Linear delivers cutting-edge motion solutions to meet industry demands.

Environmental Considerations

Modern linear slide guides focus on sustainability and energy efficiency:

Eco-friendly lubricants reduce contamination.

Recyclable materials promote green manufacturing.

Low-friction systems minimize energy consumption.

YH Linear continues to innovate for both performance and environmental responsibility.

FAQs

What is a linear slide guide used for?

It’s used to provide precise, low-friction linear motion in machinery and automation systems.

What are the types of linear slide guides?

Ball-type, roller-type, cross roller, miniature, and heavy-duty guides.

How long does a linear slide guide last?

With proper maintenance, it can last tens of thousands of operational hours.

Are linear slide guides interchangeable between brands?

Some models follow standard dimensions, but compatibility should always be verified.

Do linear slide guides need lubrication?

Yes, periodic lubrication prevents wear and ensures smooth motion.

Conclusion

The linear slide guide is a cornerstone of precision engineering, delivering unmatched accuracy, rigidity, and performance. From miniature designs for delicate instruments to heavy-duty systems in industrial machinery, these components ensure the future of motion control remains fast, reliable, and efficient.

With innovation and quality at its core, YH Linear continues to lead the way in delivering world-class linear motion solutions for industries worldwide.