Outline for Rail Bearing

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Rail Bearing | Importance of rail bearing in railways, How rail bearing works |

| Rail Bearing | Definition, Historical development |

| Types of Rail Bearing | Plain bearings, Roller bearings, Ball bearings, Spherical bearings, Needle bearings |

| Components of Rail Bearing | Bearing housing, Inner and outer race, Rolling elements, Seals and shields |

| Functions of Rail Bearing | Load distribution, Reduction of friction, Smooth movement, Noise reduction |

| Role of Rail Bearing in Rail Transport | Stability in trains, Safety considerations, Passenger comfort |

| Advantages of Rail Bearing | Longer lifespan of rail vehicles, Cost efficiency, Energy saving |

| Disadvantages of Rail Bearing | Wear and tear, Maintenance challenges |

| Rail Bearing Materials | Steel, Bronze, Composite materials |

| Manufacturing Process of Rail Bearing | Forging, Heat treatment, Precision grinding |

| Installation of Rail Bearing | Step-by-step process, Common mistakes during installation |

| Rail Bearing Lubrication | Importance of lubrication, Types of lubricants, Lubrication intervals |

| Common Rail Bearing Failures | Overheating, Misalignment, Corrosion, Fatigue |

| Signs of Rail Bearing Problems | Excessive noise, Vibration, Increased temperature |

| Rail Bearing Maintenance | Preventive maintenance, Predictive maintenance |

| Testing Rail Bearing Performance | Load testing, Vibration analysis, Temperature monitoring |

| Modern Innovations in Rail Bearing | Smart bearings, Condition monitoring sensors |

| Rail Bearing in High-Speed Trains | Special requirements, Enhanced durability |

| Environmental Impact of Rail Bearing | Recycling, Energy efficiency |

| Global Standards for Rail Bearing | ISO standards, Railway-specific regulations |

| Future of Rail Bearing | Technological advancements, Sustainability trends |

| Applications Beyond Railways | Industrial use, Automotive sector |

| Comparison of Rail Bearing with Other Bearings | Similarities, Differences |

| Rail Bearing Cost and Market Trends | Price variations, Key manufacturers |

| Conclusion | Summary of importance, Final thoughts |

| FAQs | At least six relevant FAQs |

Introduction to Rail Bearing

Rail bearing may seem like a small component in the grand machinery of a railway system, but it is one of the most critical. Without rail bearings, trains would struggle with excessive friction, frequent breakdowns, and dangerous instability. Acting as a mediator between the wheel and the axle, the bearing ensures smooth rotation, controlled load distribution, and safety for both freight and passenger trains.

Every train you see on the tracks, whether it’s a high-speed bullet train or a heavy cargo hauler, depends on its bearings to keep moving efficiently. The quality and design of these bearings determine not only how well a train performs but also how safe the ride is for passengers and goods alike.

Rail Bearing

A rail bearing is a specialized mechanical device that supports both radial and axial loads in a railway axle. In simpler terms, it helps the wheels spin freely while carrying the enormous weight of the train. Its primary job is to reduce friction and wear between moving parts.

The earliest rail systems used plain bearings made from brass or bronze, which were functional but required constant lubrication and maintenance. As rail speeds increased, engineers realized the need for stronger, longer-lasting solutions. This led to the adoption of roller bearings, which are now the gold standard in rail systems worldwide.

Modern rail bearings are designed to handle extreme forces while remaining compact, durable, and energy-efficient. Many rail companies are also adopting smart bearings that can sense temperature, vibration, and stress levels in real time, helping to predict and prevent failures before they occur.

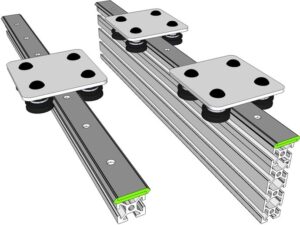

Types of Rail Bearing

Rail bearings come in different designs, each suited for specific needs:

Plain Bearings – Oldest type, made of bronze or brass, but prone to overheating and high friction.

Roller Bearings – Cylindrical rollers that handle heavy radial loads; widely used in modern railways.

Ball Bearings – Lightweight and efficient, but less common in heavy-duty rail use.

Spherical Bearings – Can accommodate misalignment between axle and housing, useful for uneven tracks.

Needle Bearings – Compact but strong, designed for smaller spaces with high load capacity.

Selecting the right bearing type depends on train speed, weight, and track conditions. For instance, high-speed passenger trains typically use advanced roller bearings, while older freight trains may still operate with plain bearings.

Components of Rail Bearing

A rail bearing is not a single piece but a combination of several critical parts:

Bearing Housing – Protects the internal components and ensures proper mounting.

Inner and Outer Race – The rings on which rolling elements rotate.

Rolling Elements – Balls or rollers that carry the load.

Seals and Shields – Prevent dust, dirt, and moisture from entering.

Each part is engineered to handle specific stress levels. If one component fails, the entire bearing can malfunction, putting the train at risk.

Functions of Rail Bearing

The functions of a rail bearing extend beyond simply reducing friction. It plays a central role in:

Load Distribution – Evenly spreads the enormous weight of the train across the axle.

Smooth Movement – Enables stable and efficient wheel rotation.

Noise Reduction – Reduces squealing and grinding sounds during operation.

Safety – Prevents overheating and axle seizure that could cause derailments.

In essence, without rail bearings, trains would not run as we know them today.

Role of Rail Bearing in Rail Transport

The importance of rail bearings in rail transport cannot be overstated:

Stability in Trains – Ensures that even at high speeds, trains remain steady.

Safety Considerations – Prevents critical failures that could lead to accidents.

Passenger Comfort – Reduces vibration and noise inside the train compartments.

Bearings are a silent contributor to a smooth, safe, and enjoyable journey.

Advantages of Rail Bearing

The adoption of modern rail bearings offers several benefits:

Longer Lifespan of Rail Vehicles – Bearings protect axles from wear.

Cost Efficiency – Reduces repair and replacement costs.

Energy Saving – Minimizes rolling resistance, reducing fuel consumption.

Enhanced Safety – Prevents catastrophic failures by handling extreme stress.

Disadvantages of Rail Bearing

Despite the advantages, rail bearings do come with challenges:

Wear and Tear – Even the best bearings degrade over time.

Maintenance Needs – Bearings require regular inspection and lubrication.

Cost of Replacement – High-quality bearings can be expensive.

Failure Risks – Sudden failure can halt train operations.

Rail Bearing Materials

The choice of material defines the durability of the bearing:

Steel – Strong, reliable, and most common.

Bronze – Used in older plain bearings.

Composite Materials – Lightweight and corrosion-resistant, ideal for modern designs.

Advances in metallurgy have led to tougher and longer-lasting bearings.

Manufacturing Process of Rail Bearing

The production of a rail bearing involves precision:

Forging – Shapes the initial steel body.

Heat Treatment – Hardens the steel for durability.

Precision Grinding – Ensures accuracy in the races and rolling elements.

Every bearing must undergo strict quality control to meet global safety standards.

Installation of Rail Bearing

Installing a rail bearing requires care and precision:

Cleaning and preparing the axle.

Heating the bearing for expansion.

Carefully pressing the bearing onto the axle.

Securing with housing and seals.

Lubricating before use.

Common mistakes include misalignment and improper lubrication, both of which can lead to premature failure.

Rail Bearing Lubrication

Lubrication is the lifeline of rail bearings. It reduces friction, prevents overheating, and extends lifespan.

Types of Lubricants – Grease and oil.

Lubrication Intervals – Vary depending on usage, but regular checks are essential.

A poorly lubricated bearing is a ticking time bomb in rail operations.

Common Rail Bearing Failures

Despite engineering advances, failures still occur:

Overheating – Often caused by poor lubrication.

Misalignment – Leads to uneven stress and early wear.

Corrosion – From water or chemical exposure.

Fatigue – Micro-cracks forming over time under repeated stress.

Understanding these causes helps prevent costly breakdowns.

Signs of Rail Bearing Problems

Train operators and engineers must watch out for warning signs:

Unusual noise during operation.

Excessive vibration in the wheels.

Temperature rise beyond safe limits.

Oil leaks or grease contamination.

Early detection prevents major disasters.

Rail Bearing Maintenance

Maintenance is the backbone of safe train operation:

Preventive Maintenance – Scheduled inspections and lubrication.

Predictive Maintenance – Using sensors and AI to detect problems before failure.

Modern predictive systems save millions in repair costs and prevent unexpected delays.

Testing Rail Bearing Performance

Testing ensures reliability and safety:

Load Testing – Simulating train loads to check bearing strength.

Vibration Analysis – Detecting imbalances or early damage.

Temperature Monitoring – Preventing overheating and lubrication failure.

Modern Innovations in Rail Bearing

Technology is transforming rail bearings:

Smart Bearings – Equipped with sensors for real-time monitoring.

Condition Monitoring Systems – Integrated into trains for automated diagnostics.

Improved Materials – Lightweight composites reducing energy consumption.

Rail Bearing in High-Speed Trains

High-speed rail demands specialized bearings:

Must withstand higher rotational speeds.

Require enhanced lubrication systems.

Need advanced materials to handle extreme stress.

Without specialized bearings, high-speed trains would risk catastrophic failure.

Environmental Impact of Rail Bearing

Sustainability is shaping the future of rail bearings:

Recycling of steel components reduces waste.

Energy Efficiency lowers overall carbon footprint.

Longer Lifespan reduces replacement needs.

Green rail bearing solutions are becoming an industry focus.

Global Standards for Rail Bearing

Rail bearings must meet strict regulations:

ISO Standards – Define safety and durability.

UIC (International Union of Railways) – Sets railway-specific standards.

National Regulations – Countries often add their own safety requirements.

Compliance ensures global interoperability of railway systems.

Future of Rail Bearing

The future points toward:

Smart, self-monitoring bearings.

Sustainable materials and manufacturing.

AI-driven predictive maintenance.

The rail bearing of tomorrow will not just rotate but also communicate, predict, and self-protect.

Applications Beyond Railways

While essential in trains, bearings also appear in:

Automotive – Cars, trucks, and buses.

Industrial Machinery – Conveyor systems and turbines.

Aerospace – Aircraft landing gears.

Their versatility shows the universal importance of bearings.

Comparison of Rail Bearing with Other Bearings

Rail bearings differ significantly from regular ones:

Similarities – Reduce friction, allow rotation.

Differences – Rail bearings handle much heavier loads, extreme conditions, and require higher safety standards.

Rail Bearing Cost and Market Trends

The rail bearing market is booming:

Cost – Varies from hundreds to thousands of dollars per bearing.

Key Manufacturers – SKF, Timken, NTN, NSK, Schaeffler.

Market Growth – Driven by high-speed rail projects and freight expansions.

Conclusion

Rail bearings may not grab headlines, but they keep the world’s railways running safely and efficiently. From high-speed passenger trains to heavy freight locomotives, rail bearings quietly handle the toughest tasks—supporting massive loads, ensuring stability, and reducing energy consumption.

As technology advances, future rail bearings will become smarter, greener, and more efficient, shaping the future of global rail transport.

FAQs

What is a rail bearing?

A rail bearing is a mechanical component that supports loads between the axle and wheel, ensuring smooth rotation with minimal friction.

Why are rail bearings important in trains?

They ensure safety, reduce wear and tear, and improve passenger comfort by stabilizing the wheelset.

What are the common types of rail bearings?

Plain, roller, ball, spherical, and needle bearings.

How often should rail bearings be maintained?

Regular inspections should be scheduled every few months, with lubrication checks depending on usage.

What are the signs of a failing rail bearing?

Excessive noise, vibration, overheating, and lubricant leakage.

Which companies manufacture rail bearings?

Major manufacturers include SKF, Timken, Schaeffler, NSK, and NTN.

Inbound and Outbound Link Suggestions

Inbound Links (Internal):

Link to articles on railway safety systems

Link to train axle technology

Link to railway maintenance best practices

Outbound Links (External):