Outline for “Rail Guide”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Rail Guide Systems | Definition, Importance in Motion Engineering |

| What is a Rail Guide? | Concept, Basic Working |

| History of Rail Guide Technology | From Early Tracks to Modern Precision Systems |

| Key Components of Rail Guide Systems | Rails, Carriages, Rolling Elements |

| How Rail Guides Work | Motion Mechanism, Load Handling |

| Different Types of Rail Guides | Linear Rail Guides, Roller Rail Guides, Ball Rail Guides, Plain Rail Guides |

| Linear Rail Guide | Structure, Benefits, Common Applications |

| Roller Rail Guide | Heavy Load Handling, Industrial Uses |

| Ball Rail Guide | Precision Motion, CNC & Robotics |

| Plain Rail Guide | Simplicity, Maintenance-Free Options |

| Advantages of Rail Guide Systems | Smooth Motion, Accuracy, Efficiency |

| Applications of Rail Guides in Industry | Manufacturing, Robotics, Medical Equipment, Automotive |

| Rail Guide in Robotics | Automation, High-Speed Movements |

| Rail Guide in CNC Machines | Precision Cutting, Engraving, Milling |

| Rail Guide in Medical Equipment | Imaging Machines, Surgical Robots |

| Choosing the Right Rail Guide | Load Capacity, Speed, Environment |

| Factors That Influence Rail Guide Performance | Lubrication, Alignment, Wear Resistance |

| Installation Process of Rail Guides | Step-by-Step Setup, Tools Needed |

| Maintenance of Rail Guide Systems | Cleaning, Lubrication, Inspections |

| Common Issues in Rail Guides and Fixes | Noise, Misalignment, Wear Problems |

| Future Trends in Rail Guide Technology | Smart Rail Guides, IoT Integration |

| Top Rail Guide Manufacturers | THK, NSK, HIWIN, SKF |

| Cost of Rail Guides | Price Factors, Value Analysis |

| Rail Guide vs. Traditional Slide Systems | Comparison of Features |

| Rail Guide | Recap of Benefits and Growth |

| FAQs | Six Most Common Questions |

| Conclusion | Final Insights and Takeaways |

Introduction to Rail Guide Systems

Rail guide systems are at the heart of precision engineering, ensuring smooth, linear motion across countless machines and devices. From CNC machining centers to surgical robots, rail guides play a critical role in providing frictionless movement, high accuracy, and long-term durability. Without them, industries like manufacturing, robotics, and healthcare would face significant challenges in achieving precision and efficiency.

What is a Rail Guide?

A rail guide is a motion system designed to guide moving parts along a linear path with minimal friction. Unlike sliding guides, rail guides often use rolling elements such as balls or rollers, which allow carriages to move smoothly across rails while carrying significant loads.

History of Rail Guide Technology

The concept of guiding movement along rails dates back centuries, starting with simple grooves and sliding surfaces. The industrial revolution introduced steel tracks for machinery, but they wore quickly. With the development of ball and roller bearings in the 20th century, rail guide technology advanced dramatically. Today, modern rail guides are engineered with high-strength materials, surface treatments, and precision rolling elements for superior accuracy.

Key Components of Rail Guide Systems

Rail guides consist of:

Rails – The stationary structure providing the track.

Carriages (Blocks) – The moving component carrying loads.

Rolling Elements – Balls, rollers, or needles that reduce friction.

Housing and Seals – Protect the system from dust and wear.

How Rail Guides Work

Rail guides work on rolling motion principles. When force is applied, the carriage moves along the rail with rolling elements transferring the load. This reduces friction significantly compared to sliding systems. The result is smooth, accurate, and repeatable linear motion.

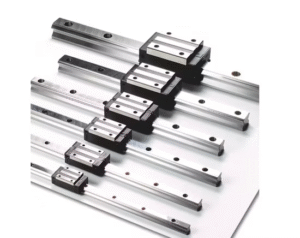

Different Types of Rail Guides

Rail guides come in several variations, each with unique features:

Linear Rail Guides – For high-precision applications.

Roller Rail Guides – For heavy-duty machinery.

Ball Rail Guides – For smooth, precise movement.

Plain Rail Guides – Simple, low-maintenance designs.

Linear Rail Guide

Linear rail guides are among the most commonly used. They provide excellent accuracy, high rigidity, and smooth motion. These are widely used in CNC machines, semiconductor equipment, and laboratory instruments.

Roller Rail Guide

Roller rail guides use cylindrical rollers instead of balls. They have higher rigidity and can withstand heavy loads, making them ideal for injection molding machines, presses, and industrial robotics.

Ball Rail Guide

Ball rail guides rely on recirculating steel balls. They offer smooth, high-speed motion with excellent accuracy, commonly used in CNC machining, automation, and robotic systems.

Plain Rail Guide

Plain rail guides use sliding surfaces rather than rolling elements. They are simpler, often self-lubricating, and suitable for quiet, low-speed applications.

Advantages of Rail Guide Systems

Rail guides provide:

High precision and repeatability

Smooth and quiet motion

High load capacity

Long service life

Energy efficiency due to low friction

Applications of Rail Guides in Industry

Rail guides are widely used in:

Manufacturing – Assembly lines, automation equipment

Robotics – High-speed, accurate motion systems

Medical Equipment – MRI, CT scanners, surgical robots

Automotive Industry – Testing equipment, assembly systems

Rail Guide in Robotics

In robotics, rail guides ensure precision and stability. They allow robots to perform high-speed operations with minimal vibration, which is vital in assembly lines and automation.

Rail Guide in CNC Machines

CNC machines depend heavily on rail guides for precision. Rail guides ensure smooth tool paths, which is critical in cutting, milling, and engraving processes.

Rail Guide in Medical Equipment

In medical imaging and robotic surgery, rail guides provide smooth, controlled motion. Precision is vital in such fields, and rail guides ensure patient safety and accurate results.

Choosing the Right Rail Guide

Factors to consider include:

Load requirements

Accuracy needs

Speed and acceleration

Environmental conditions (dust, humidity, temperature)

Factors That Influence Rail Guide Performance

Proper lubrication

Correct alignment during installation

High-quality materials

Regular inspections

Installation Process of Rail Guides

Installing a rail guide involves:

Preparing a clean surface

Aligning rails accurately

Securing with proper torque

Testing smooth motion

Maintenance of Rail Guide Systems

Maintenance includes lubrication, cleaning, and periodic inspection. Using dust covers or seals extends the lifespan of rail guides.

Common Issues in Rail Guides and Fixes

Noise and vibration – Caused by poor lubrication.

Misalignment – Results in uneven wear.

Excessive wear – Often from overload or dirt ingress.

Future Trends in Rail Guide Technology

Next-generation rail guides will feature:

Smart sensors for condition monitoring

IoT integration for predictive maintenance

Advanced coatings for wear resistance

Lighter, stronger materials

Top Rail Guide Manufacturers

Leading global manufacturers include:

THK (Japan)

NSK (Japan)

HIWIN (Taiwan)

SKF (Sweden)

Cost of Rail Guides

Rail guides vary in cost based on size, precision, and load capacity. Entry-level rail guides may cost around $50, while heavy-duty industrial models can exceed several thousand dollars.

Rail Guide vs. Traditional Slide Systems

| Feature | Rail Guide | Slide System |

|---|---|---|

| Friction | Low | High |

| Precision | High | Moderate |

| Durability | Long-lasting | Prone to wear |

| Load Capacity | High | Limited |

| Cost | Higher upfront | Lower |

Rail Guide

The rail guide is not just a machine part—it is the foundation of precision motion across industries. Its role in ensuring efficiency, accuracy, and smooth operation continues to expand as industries evolve.

FAQs

What is the main purpose of a rail guide?

It enables smooth, precise, and low-friction linear motion.

Are rail guides expensive?

Prices vary, but they are a long-term investment due to durability.

Do rail guides need lubrication?

Yes, lubrication is vital for performance and longevity.

Can rail guides handle heavy loads?

Yes, roller rail guides are designed for high-load applications.

What industries use rail guides the most?

Manufacturing, robotics, automotive, and healthcare.

What is the difference between ball and roller rail guides?

Ball guides offer smooth, high-speed motion, while roller guides provide higher rigidity and load capacity.

Conclusion

Rail guides are the backbone of precision engineering. Their ability to deliver frictionless, accurate, and reliable linear motion makes them indispensable in robotics, manufacturing, and healthcare. With future innovations like IoT integration and smart sensors, rail guide systems will continue to redefine industrial automation.

Suggested Inbound Links:

Internal article on automation in robotics

Guide on CNC machining essentials

Blog on industrial maintenance best practices