Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Linear Bearing Slide Rail Overview | linear motion rail |

| What Is a Linear Bearing Slide Rail? | rail bearing guide |

| Why Linear Bearing Slide Rail Systems Matter | smooth motion |

| How a Linear Bearing Slide Rail Works | rolling elements |

| Main Components of a Linear Bearing Slide Rail | rail, carriage |

| Types of Linear Bearing Slide Rail Systems | ball, roller |

| Choosing Between Ball and Roller Slide Rails | comparison |

| Load Capacity of Linear Bearing Slide Rails | dynamic load |

| Linear Bearing Slide Rail Materials | steel, alloys |

| Coating Options for Slide Rails | corrosion protection |

| Mounting Linear Bearing Slide Rails Correctly | installation |

| Alignment Techniques for Linear Bearing Slide Rails | straightness |

| Lubrication Requirements | grease, oil |

| Preload in Linear Bearing Slide Rails | stiffness |

| Noise and Vibration Behavior | damping |

| Common Issues in Slide Rail Systems | wear, binding |

| How to Increase Slide Rail Lifespan | maintenance |

| Linear Bearing Slide Rails for CNC Machinery | machining |

| Slide Rails in Automation and Robotics | robotics |

| Slide Rails for 3D Printers and Laser Cutters | maker tools |

| Thermal Effects on Slide Rail Performance | heat expansion |

| Shock and Impact Resistance | durability |

| Compact and Miniature Slide Rail Options | micro rails |

| Cost Factors When Buying Slide Rails | pricing |

| Innovations in Slide Rail Engineering | new technology |

| Real-World Applications of Slide Rail Systems | industries |

| Maintenance Checklist | inspection |

| Conclusion | summary |

Linear Bearing Slide Rail

Introduction

The keyword linear bearing slide rail appears early in this introduction to support SEO goals and improve clarity. If you work with CNC machines, robots, automated production lines, or even custom DIY motion systems, you’ve probably seen how important stable linear motion is. The linear bearing slide rail makes it all possible.

This rail-and-carriage system provides smooth, controlled, low-friction movement along a straight path. It handles weight, speed, vibration, and repeated cycles without losing accuracy. Although the system appears simple, many factors influence its performance—rail hardness, preload, lubrication, alignment, and rolling element design. In this guide, everything is explained using easy sentences and clear transitions so the information feels natural and practical.

Linear Bearing Slide Rail Overview

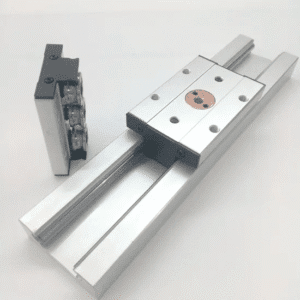

A linear bearing slide rail is a precision motion system that guides movement in one direction with low friction. It uses a hardened rail and a bearing carriage filled with rolling elements. Together, they create smooth and dependable movement used in machines of all sizes.

What Is a Linear Bearing Slide Rail?

A linear bearing slide rail is a mechanical guidance system that allows precise linear travel using bearing-supported sliders. The bearing elements reduce friction. The rail keeps travel straight. The setup delivers reliable and repeatable motion even under significant loads.

Why Linear Bearing Slide Rail Systems Matter

Modern machines demand stability. A linear bearing slide rail offers:

Smooth, quiet movement

Higher positional accuracy

Lower friction

Longer service life

High-speed motion

Reliable load handling

These benefits help machines work better and last longer.

How a Linear Bearing Slide Rail Works

Inside the carriage, balls or rollers circulate along hardened tracks. As the carriage moves, these elements roll instead of slide. Rolling friction is much lower, which keeps movement smooth. This also reduces heat and wear.

Main Components of a Linear Bearing Slide Rail

A complete system includes:

Rail: Hardened and precision-ground

Carriage: Holds rolling elements

Rolling elements: Balls or rollers

End caps: Guide element circulation

Wipers: Remove dust

Grease ports: Supply lubrication

Every part supports motion stability.

Types of Linear Bearing Slide Rail Systems

Common types include:

Ball-bearing slide rails

Roller-bearing slide rails

Dual-block slide rails

Miniature slide rails

Wide-body slide rails

Each type offers different benefits.

Choosing Between Ball and Roller Slide Rails

Ball-bearing rails offer:

Smooth movement

Lower friction

Higher speeds

Roller-bearing rails offer:

Higher load capacity

Greater rigidity

Better resistance to shock

The right choice depends on your machine’s demands.

Load Capacity of Linear Bearing Slide Rails

Load ratings depend on:

Rolling element size

Rail height

Carriage length

Preload level

Mounting surface quality

Heavier machines require wide or roller-based rails.

Linear Bearing Slide Rail Materials

Rails are usually made of:

High-carbon tool steel

Bearing-grade steel

Stainless steel

Alloy steel

These materials resist wear, bending, and heat.

Coating Options for Slide Rails

Coatings improve corrosion and wear resistance:

Hard chrome

Nickel plating

Black oxide

Advanced multi-layer coatings

Coatings extend lifespan in tough environments.

Mounting Linear Bearing Slide Rails Correctly

Correct mounting prevents binding and wear. Tips include:

Clean mounting surfaces

Remove all dust and chips

Tighten bolts in sequence

Don’t force the carriage

Test for smooth motion during installation

A flat mounting surface is extremely important.

Alignment Techniques for Linear Bearing Slide Rails

Proper alignment delivers better accuracy. Techniques include:

Using straightedges

Using dial indicators

Using alignment pins

Matching parallel rails carefully

Good alignment reduces friction and increases lifespan.

Lubrication Requirements

Lubrication reduces wear and supports smooth travel. Grease works well for slow, heavy motion. Oil works better for fast, hot, or high-speed systems.

Preload in Linear Bearing Slide Rails

Preload removes tiny internal clearances. It increases stiffness. Although preload improves accuracy, too much increases friction. Machines usually choose medium preload for balanced performance.

Noise and Vibration Behavior

Noise often comes from:

Poor alignment

High load

Dirty rails

Dry lubrication

Roller rails tend to run quieter under heavy load.

Common Issues in Slide Rail Systems

Mistakes include:

Improper lubrication

Rail contamination

Misalignment

Excessive preload

Bolt loosening

These issues reduce accuracy and speed.

How to Increase Slide Rail Lifespan

For long life:

Clean rails regularly

Lubricate often

Maintain proper preload

Use wipers and dust covers

Avoid overloading

Simple routines help keep rails smooth.

Linear Bearing Slide Rails for CNC Machinery

CNC machines rely on:

Rigidity

Speed

Repeatability

A good slide rail prevents backlash, chatter, and vibration.

Slide Rails in Automation and Robotics

Robotic systems need rails for:

Pick-and-place motion

Conveyor movement

Gantry stability

High-speed cycles

Slide rails help robots move predictably.

Slide Rails for 3D Printers and Laser Cutters

In these systems, a linear bearing slide rail offers:

Quiet movement

Smooth travel

Light load capability

Precise positioning

It upgrades accuracy and print quality.

Thermal Effects on Slide Rail Performance

Heat causes rail expansion. Even small temperature changes impact precision. Machines must consider thermal compensation.

Shock and Impact Resistance

Roller rails resist shocks better than ball rails. High-impact environments need thick rails with reinforced carriages.

Compact and Miniature Slide Rail Options

Mini slide rails suit:

Micro robotics

Medical equipment

Small automation tools

Electronic manufacturing

Their small size allows tight, delicate motion.

Cost Factors When Buying Slide Rails

Pricing depends on:

Rail size

Carriage type

Brand

Material

Coating

Precision grade

Better rails cost more but last longer.

Innovations in Slide Rail Engineering

Recent advancements include:

Self-lubricating blocks

Ceramic rolling elements

Lightweight carbon-reinforced rails

Noise-reducing groove designs

These innovations continue improving performance.

Real-World Applications of Slide Rail Systems

Linear bearing slide rails appear in:

CNC routers

Pick-and-place robots

Automated testing devices

Medical scanners

3D printers

Packaging machines

They support almost every motion-critical industry.

Maintenance Checklist

A good maintenance routine includes:

Weekly cleaning

Monthly lubrication

Quarterly bolt tightening

Routine preload checks

Seal inspections

Rail straightness checks

Consistent care keeps your system operating like new.

Conclusion

A linear bearing slide rail is one of the most important components in modern linear motion design. Its ability to carry loads, maintain alignment, and move smoothly makes it essential for CNC machines, robotics, automation systems, and precision tools. With correct sizing, proper lubrication, and accurate alignment, a linear bearing slide rail delivers years of stable performance.

FAQs

What is a linear bearing slide rail used for?

It guides smooth and accurate linear movement in machines.

Do slide rails need lubrication?

Yes. Lubrication reduces friction and improves lifespan.

Are ball or roller slide rails better?

Ball rails are smoother. Roller rails handle more load.

Can slide rails handle heavy loads?

Yes, especially wide and roller-based types.

Where are slide rails used most?

CNC machines, robotics, packaging, and automation equipment.

How long do slide rails last?

With good maintenance, many last for years or even decades.

Internal Link Suggestions

Linear guide rails

Linear bearing rail

Linear guide slider

Heavy duty linear rail

Outbound Link Suggestions

HIWIN linear slides technical PDF

NSK motion components reference