Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Slide Rail Overview | linear motion, guide rail |

| Why the Linear Slide Rail Is Important | precision movement |

| How a Linear Slide Rail Works | sliding block, rolling elements |

| Components of a Linear Slide Rail System | carriage, tracks |

| Types of Linear Slide Rail Designs | profile rail, round rail |

| Ball-Type Linear Slide Rails | ball bearings |

| Roller-Type Linear Slide Rails | roller bearings |

| Miniature Linear Slide Rail Systems | micro linear motion |

| Heavy-Duty Linear Slide Rails | industrial strength |

| Advantages of Using a Linear Slide Rail | accuracy, durability |

| Applications of Linear Slide Rail Systems | CNC, automation |

| How to Choose the Right Linear Slide Rail | load, speed |

| Installation Steps for Linear Slide Rails | alignment, mounting |

| Lubrication for Linear Slide Rails | grease, oil |

| Maintenance Tips | cleaning, inspection |

| Common Problems in Linear Slide Rails | contamination |

| Troubleshooting Motion Issues | vibration, noise |

| Linear Slide Rail vs Linear Guide Rail | comparison |

| Material Selection for Linear Slide Rails | carbon steel, stainless |

| Environmental Effects on Linear Slide Rails | dust, coolant |

| High-Speed Capabilities of Linear Slide Rails | acceleration |

| Understanding Load Ratings | static load, dynamic load |

| Cost Considerations for Linear Slide Rails | pricing factors |

| Modern Technology and Innovations | self-lubricating systems |

| Safety Practices with Linear Slide Rails | guarding |

| Cleaning Procedures for Slide Rails | solvents, cloths |

| How Linear Slide Rails Improve CNC Accuracy | rigidity |

| Top Manufacturers of Linear Slide Rails | global brands |

| Checklist Before Purchasing a Linear Slide Rail | specifications |

| Conclusion | summary |

Introduction

The advancement of modern automation depends on precise, durable, and reliable motion hardware. One component that stands out is the linear slide rail, a guiding system that supports smooth and accurate straight-line movement. Because the phrase linear slide rail appears directly in the introduction, it immediately communicates the article’s focus to readers and search engines.

This guide uses simple English, short sentences, and smooth transitional phrasing. It’s written in a helpful and optimistic tone, drawing on real industrial experience to explain how linear slide rails work, why they matter, and where they’re used. Whether you’re designing new machinery, maintaining equipment, or researching ways to improve automation accuracy, this article provides deep, practical insights.

Linear Slide Rail Overview

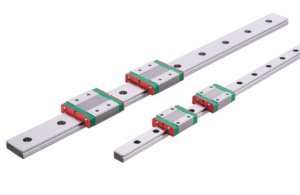

A linear slide rail is a precision-guiding track that allows a block or carriage to move along a straight path. Instead of sliding metal on metal, the block uses rolling elements—balls or rollers—to reduce friction and maintain accuracy. This design creates stable movement with low resistance, making it ideal for machines that require predictable and repeatable motion.

Linear slide rails are essential in industries where accuracy matters, such as CNC machining, robotics, automated assemblies, and medical devices.

Why the Linear Slide Rail Is Important

Linear slide rails matter because they offer:

High accuracy

Low friction

Strong load handling

Excellent rigidity

Smooth motion

Quiet operation

Long lifespan

Modern manufacturing demands speed and accuracy. A quality linear slide rail allows machines to meet those expectations with confidence.

How a Linear Slide Rail Works

A linear slide rail works by guiding a carriage block along a hardened steel rail. Inside the block, rolling elements circulate in a loop, allowing effortless motion. As the block moves, the elements rotate and recirculate, spreading load across many contact points.

This rolling design minimizes wear, reduces noise, and keeps motion smooth even after long usage.

Components of a Linear Slide Rail System

Every rail system includes:

Rail – precision-ground metal track

Carriage block – sliding unit containing bearings

Ball or roller bearings – reduce friction

End caps – guide rolling element recirculation

Seals – block dirt and debris

Lubrication ports – for grease or oil

Retainer cage – keeps bearings aligned

All components work together to deliver stable and accurate linear movement.

Types of Linear Slide Rail Designs

There are two major types:

Profile (square) rails

These provide extremely high rigidity and precision. They are the standard for CNC machines and industrial systems.

Round rails

These offer easier alignment and perform well in lighter machines.

Both types have their place depending on the application.

Ball-Type Linear Slide Rails

These use steel balls inside the block. Their benefits include:

Smooth, quiet movement

Low friction

High travel speed

Excellent positioning accuracy

Ball-type rails suit applications that require fast and gentle motion.

Roller-Type Linear Slide Rails

Roller rails use cylindrical rollers. They provide:

Higher load capacity

Greater stiffness

Strong vibration resistance

Improved durability

They perform extremely well in heavy-duty cutting or high-speed industrial machines.

Miniature Linear Slide Rail Systems

Miniature slide rails are used in:

Optical instruments

Medical equipment

Small robots

Micro-assembly systems

Precision measuring devices

Their compact structure makes them ideal for tight spaces.

Heavy-Duty Linear Slide Rails

Heavy-duty rails are built for strength. They include:

Reinforced bearing blocks

Larger rolling elements

Stronger seals

Heat-treated rails

They are perfect for industrial automation, gantry systems, and robotics.

Advantages of Using a Linear Slide Rail

Key advantages include:

Smooth travel

High precision

Resistance to bending

Stable motion even under load

Low maintenance

Quiet operation

Excellent repeatability

These qualities make linear slide rails indispensable in advanced engineering.

Applications of Linear Slide Rail Systems

Linear slide rails appear in countless machines, such as:

CNC mills

CNC routers

Robotic arms

Laser cutters

3D printers

Packaging systems

Medical imaging devices

Industrial conveyors

Pick-and-place robots

Their versatility supports both heavy and delicate applications.

How to Choose the Right Linear Slide Rail

Consider the following:

Required load capacity

Length of travel

Speed requirements

Precision needs

Installation space

Environmental factors

Temperature limits

Block style (standard, wide, long)

Noise levels

Lubrication frequency

Selecting the correct rail optimizes performance and reduces wear.

Installation Steps for Linear Slide Rails

Proper installation is crucial. Steps include:

Clean the mounting surface thoroughly.

Check flatness using a straight edge.

Position the rail with loose bolts.

Tighten bolts gradually and evenly.

Align the rail using a dial indicator.

Install the block and test the motion.

Add lubrication before full operation.

Correct installation prevents binding, noise, and premature failure.

Lubrication for Linear Slide Rails

Lubrication improves:

Smoothness

Lifespan

Noise reduction

Accuracy

Common lubrication types:

Grease (general-purpose, high-temp, lithium-based)

Oil (light machine oil, synthetic oil)

Self-lubricating cartridges

Always follow the manufacturer’s guidelines.

Maintenance Tips

To maintain top performance:

Clean rails regularly

Lubricate blocks on schedule

Inspect for debris

Replace worn seals

Check bolt torque

Listen for unusual sounds

Keep the machine environment clean

Proper maintenance prevents costly downtime.

Common Problems in Linear Slide Rails

Typical issues include:

Binding

Rough movement

Noise

Heat buildup

Bearing wear

Debris contamination

Misalignment

Recognizing issues early helps avoid damage.

Troubleshooting Motion Issues

If motion becomes rough:

Clean the rail

Re-lubricate

Check for misalignment

Inspect seals and bearings

Ensure bolts are evenly tightened

If noise increases:

Add lubrication

Check for dirt

Inspect the block’s internal bearings

Small fixes often restore performance.

Linear Slide Rail vs Linear Guide Rail

These terms are often used interchangeably, but:

| Feature | Linear Slide Rail | Linear Guide Rail |

|---|---|---|

| Design | Sliding block on rail | Precision-guided rolling block |

| Use | Light to medium loads | High precision & heavy loads |

| Precision | Good | Very high |

| Best For | Light automation | CNC, robotics |

In many industries, they mean the same thing—but the guide rail often refers to the high-precision profile type.

Material Selection for Linear Slide Rails

Common materials include:

Carbon steel — strong and economical

Stainless steel — corrosion-resistant

Chromed steel — smooth finish

Coated steel — excellent rust protection

Materials affect both performance and environment compatibility.

Environmental Effects on Linear Slide Rails

Challenges include:

Coolant exposure

Dust or metal chips

Humidity

Oil vapor

Chemicals

Extreme temperatures

Using protective covers greatly extends service life.

High-Speed Capabilities of Linear Slide Rails

A linear slide rail supports high-speed movement because it:

Reduces friction

Supports stable acceleration

Controls vibration

Minimizes wear

This makes it ideal for rapid automation.

Understanding Load Ratings

Load types include:

Radial loads

Lateral loads

Moment loads (pitch, roll, yaw)

Proper load selection ensures longer lifespan and better accuracy.

Cost Considerations for Linear Slide Rails

Factors that impact cost:

Rail length

Accuracy grade

Block type

Brand reputation

Coatings

Accessories

Quantity ordered

Higher-quality rails often provide better long-term value.

Modern Technology and Innovations

New innovations include:

Self-lubricating blocks

Smart sensors that monitor wear

Extremely quiet ball paths

Anti-corrosion nano coatings

Lightweight composite materials

These advancements increase reliability and performance.

Safety Practices with Linear Slide Rails

Safety requires:

Avoiding contact with moving parts

Wearing gloves during installation

Keeping rails covered during operation

Maintaining clean working spaces

Following load limits

Safety protects workers and equipment.

Cleaning Procedures for Slide Rails

To clean properly:

Wipe with lint-free cloth

Use mild solvent

Remove old grease

Check for debris

Add fresh lubrication

Clean rails function better and last longer.

How Linear Slide Rails Improve CNC Accuracy

Advantages include:

Better repeatability

Reduced vibration

Improved cutting accuracy

Stronger rigidity

Stable movement at high speeds

CNC performance is directly tied to slide rail quality.

Top Manufacturers of Linear Slide Rails

Well-known brands include:

THK

HIWIN

NSK

PMI

Bosch Rexroth

SKF

INA

Each offers reliable and high-performance motion components.

Checklist Before Purchasing a Linear Slide Rail

Before buying, confirm:

Load capacity

Accuracy grade

Rail length

Block style

Material and coatings

Noise levels

Environmental compatibility

Lubrication requirements

Mounting space

Warranty

These checks ensure proper selection.

Conclusion

A linear slide rail is one of the most important motion components in modern machinery. It offers excellent smoothness, precision, and rigidity while supporting loads with reliable consistency. Whether used in CNC machines, 3D printers, robotics, or industrial automation, linear slide rails provide the stability needed for accurate and predictable movement. With proper selection, installation, and maintenance, they will deliver outstanding performance for many years.

FAQs

What is a linear slide rail used for?

It guides straight-line movement in machinery with low friction and high accuracy.

Do linear slide rails need lubrication?

Yes, lubrication improves movement smoothness and reduces wear.

Are linear slide rails the same as linear guide rails?

They are similar, but guide rails often refer to higher-precision profile rails.

Can linear slide rails support heavy loads?

Roller-type slide rails can handle very high loads in industrial settings.

How long do linear slide rails last?

With proper maintenance, they can last many years even under demanding use.

Are linear slide rails easy to install?

They require precision, but installation is manageable with the proper steps.

Internal Link Suggestions

Link to pages discussing linear rails, linear bearings, linear motion systems, and motion components on YH.

Ideal pages: linear guide rail, linear bearings, linear motion track system.

Outbound Link Suggestions

THK Linear Guide Catalog

HIWIN Linear Motion Engineering Manual