Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Linear Rail System Overview | linear motion, rail assembly |

| What Is a Linear Rail System? | linear guide system |

| Why a Linear Rail System Matters in Modern Machines | precise motion |

| Core Components of a Linear Rail System | rail, carriage, load |

| How a Linear Rail System Works | rolling elements |

| Types of Linear Rail System Designs | ball-type, roller-type |

| Linear Rail System for Heavy Loads | industrial load rating |

| Miniature Linear Rail System Options | compact rails |

| Choosing the Right Linear Rail System Size | width, length |

| Linear Rail System Materials and Coatings | steel, stainless |

| Linear Rail System Accuracy and Tolerances | straightness |

| Mounting a Linear Rail System Properly | alignment |

| Linear Rail System Preload Explained | preload classes |

| Lubrication Needs in a Linear Rail System | grease, oil |

| Common Problems in Linear Rail Systems | noise, binding |

| How to Increase the Lifespan of a Linear Rail System | maintenance |

| Linear Rail System vs Linear Slider Systems | comparison |

| Thermal Effects in Linear Rail System Performance | temperature |

| Vibration and Noise Control in Linear Rail Systems | damping |

| Rail Stiffness and Deflection Behavior | rigidity |

| Linear Rail System in CNC Machines | machining |

| Linear Rail System in Automation and Robotics | motion control |

| Cost Factors When Choosing a Linear Rail System | budget |

| Innovations in Linear Rail System Engineering | next-gen rails |

| Real-World Applications of Linear Rail Systems | 3D printing |

| How Linear Rail Systems Improve Productivity | efficiency |

| Safety Guidelines for Linear Rail System Use | safe operation |

| Maintenance Checklist for Linear Rail Systems | inspection |

| Conclusion | summary |

Linear Rail System

Introduction

The keyword linear rail system appears early to support SEO performance and clarity. If you work with CNC machines, robotics, automation equipment, or precision assembly lines, you already know how important smooth and stable linear motion can be. A linear rail system sits at the center of these machines, quietly delivering accurate and repeatable travel every second.

Although a linear rail system seems simple at first glance, the details matter—alignment, preload, lubrication, load direction, stiffness, rail material, and surface quality. If one of these is off, the entire machine feels it. This guide breaks down everything you need using plain, clear English, short sentences, and an optimistic tone.

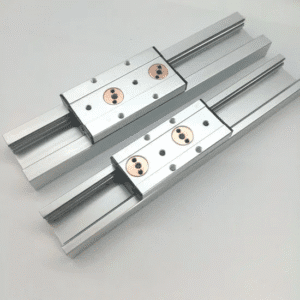

Linear Rail System Overview

A linear rail system provides stable, low-friction motion in a straight line. It uses a rail and a carriage filled with rolling elements. Together, they handle heavy loads with surprising precision. Engineers rely on these systems because they resist twisting, bending, and side forces better than many alternatives.

In most machines, the linear rail system acts like the backbone. Without it, the tool or load cannot move accurately.

What Is a Linear Rail System?

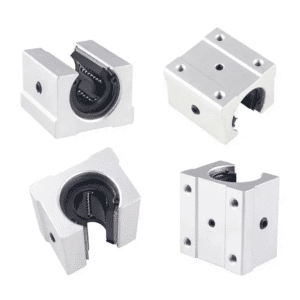

A linear rail system is a mechanical setup that guides motion along a linear path using rolling bearings. It typically includes:

A hardened rail

A bearing block or carriage

Balls or rollers

End caps and retainers

Lubrication channels

It turns linear motion into something smooth, predictable, and controlled. That reliability is why you see linear rail systems in automation factories everywhere.

Why a Linear Rail System Matters in Modern Machines

Machines today operate faster and require greater precision. A well-designed linear rail system:

Reduces friction

Handles heavy loads

Minimizes vibration

Boosts accuracy

Extends machine life

In short, it lets a machine work harder while staying stable.

Core Components of a Linear Rail System

A reliable system includes:

Rail: Hardened, precision-ground steel

Carriage: Holds the rolling elements

Balls or Rollers: Reduce friction

Seals: Keep out dust

End Caps: Guide ball circulation

Lubrication Ports: Extend lifespan

Each component plays a unique role in motion stability.

How a Linear Rail System Works

A simple principle drives the system: rolling instead of sliding. Balls or rollers move inside the carriage as it travels along the rail. This reduces friction dramatically. Because the contact surfaces are hardened, the system handles both heavy load and long travel.

Types of Linear Rail System Designs

There are two main types:

Ball-Type Rails: High speed, smooth motion, common in CNC machines.

Roller-Type Rails: Higher load capacity and rigidity, ideal for industrial automation.

Both deliver excellent precision.

Linear Rail System for Heavy Loads

Heavy-duty systems rely on:

Large roller blocks

Thick rails

Strong mounting surfaces

Proper preload

When designed well, they carry enormous loads without bending or twisting.

Miniature Linear Rail System Options

Mini systems offer:

Compact size

Smooth micro-movement

Lightweight mounting

Low noise

They’re used in electronics, medical tools, and small robots.

Choosing the Right Linear Rail System Size

Consider:

Load direction

Load weight

Mounting stiffness

Working stroke

Speed requirements

Small rails work for precise tools. Larger rails resist torque and shock loads.

Linear Rail System Materials and Coatings

Common materials include:

Hardened carbon steel

Stainless steel

Alloy steel

Coatings like chrome or black oxide improve corrosion resistance.

Linear Rail System Accuracy and Tolerances

Accuracy depends on:

Rail grinding quality

Straightness

Carriage preload

Mounting surface flatness

Small errors in the rail multiply during motion.

Mounting a Linear Rail System Properly

Mounting requires:

Clean surfaces

Tight bolt sequences

Gradual tightening

Spot checking for smooth travel

Improper mounting causes binding, noise, and misalignment.

Linear Rail System Preload Explained

Preload adds stiffness. It removes tiny clearances between rolling elements and rail surfaces. While preload improves accuracy, too much causes extra friction. Good design balances both.

Lubrication Needs in a Linear Rail System

Lubrication:

Reduces wear

Lowers heat

Improves longevity

Enhances smoothness

Grease is common, but oil works well in high-speed applications.

Common Problems in Linear Rail Systems

Typical issues include:

Dirty rails

Wrong preload

Rail twisting

Bolt loosening

Inadequate lubrication

Fixing these early prevents long-term damage.

How to Increase the Lifespan of a Linear Rail System

For long life:

Lubricate regularly

Clean rails often

Keep mounting rigid

Use correct preload

Inspect for wear

Small habits protect your investment.

Linear Rail System vs Linear Slider Systems

Linear sliders use sliding contact. Rail systems use rolling contact. Because rolling friction is lower, linear rail systems deliver more precision, faster speeds, and better rigidity.

Thermal Effects in Linear Rail System Performance

Heat expands metal. Even small temperature shifts change alignment. That’s why high-precision machines use temperature-stable materials and smart compensation.

Vibration and Noise Control in Linear Rail Systems

To reduce vibration:

Use roller rails

Increase stiffness

Add more carriages

Improve mounting surfaces

Quiet motion improves accuracy and machine comfort.

Rail Stiffness and Deflection Behavior

A stiff rail supports long travel without bending. Deflection grows as rails get longer or loads increase. Designers use thicker rails or dual-rail systems for better stability.

Linear Rail System in CNC Machines

CNC routers, mills, lathes, and laser cutters rely heavily on linear rail systems. They demand:

High rigidity

Excellent accuracy

Consistent repeatability

A CNC machine cannot function without stable rails.

Linear Rail System in Automation and Robotics

Robots depend on rails for:

Pick-and-place operations

Packaging

Assembly tasks

Conveyor transfers

Smooth travel improves cycle time and precision.

Cost Factors When Choosing a Linear Rail System

Cost depends on:

Material

Rail length

Carriage type

Precision rating

Coating

Brand

Premium rails cost more but last longer.

Innovations in Linear Rail System Engineering

Modern technology brings:

Self-lubricating blocks

Carbon fiber rail bases

Low-friction coatings

Preloaded rail frames

Smart sensors

These improvements raise performance significantly.

Real-World Applications of Linear Rail Systems

You’ll find them in:

CNC machining

3D printing

Robotics

Medical devices

Packaging machines

Inspection equipment

Any system needing precise linear motion uses them.

How Linear Rail Systems Improve Productivity

With smoother movement and better stability, machines work faster and more accurately. This reduces downtime, saves money, and improves product quality.

Safety Guidelines for Linear Rail System Use

Safety tips:

Avoid overtravel

Use end stops

Keep rails clean

Handle lubricants properly

Inspect blocks regularly

Safe operation avoids costly failures.

Maintenance Checklist for Linear Rail Systems

Recommended routine:

Clean rails weekly

Lubricate monthly

Inspect bolts quarterly

Check preload yearly

Replace seals as needed

Consistency protects precision.

Conclusion

A linear rail system plays a vital role in modern engineering. It supports precise, stable, and repeatable motion in countless industries. When designed, installed, and maintained correctly, it helps machines work with extraordinary accuracy and reliability. No matter if you’re building a CNC cutting table, a robot gantry, or an automated machine, a high-quality linear rail system makes all the difference.

FAQs

What is a linear rail system used for?

It guides loads along a straight path with smooth motion.

How long do linear rail systems last?

With proper care, many last over 10 years.

Do linear rails need lubrication?

Yes, lubrication is essential for long life and smooth travel.

Can linear rails handle heavy loads?

Roller-type rails handle very heavy loads with high stiffness.

Is alignment important for linear rail systems?

Yes, misalignment causes binding and excessive wear.

Which industries use linear rails most?

CNC machines, robotics, medical tools, and automation systems.

Internal Link Suggestions

Linear guide rails

Linear bearings and guides

Linear motion track system

Outbound Link Suggestions

THK linear motion reference

HIWIN engineering manuals

NSK linear guide design resources