Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

| Linear Rail Bearings Overview | linear bearing blocks, motion rail |

| Importance of Linear Rail Bearings | precision movement |

| How Linear Rail Bearings Work | rolling elements |

| Main Components of Linear Rail Bearings | carriages, raceways |

| Types of Linear Rail Bearings | ball bearings, roller bearings |

| Ball-Type Linear Rail Bearings | ball raceways |

| Roller-Type Linear Rail Bearings | cylindrical rollers |

| Miniature Linear Rail Bearings | small form factor |

| Heavy-Duty Linear Rail Bearings | high load capacity |

| Wide-Body Linear Rail Bearings | moment load resistance |

| Benefits of Using Linear Rail Bearings | low friction |

| Applications of Linear Rail Bearings | CNC, robotics |

| How to Select the Right Linear Rail Bearings | load ratings |

| Proper Installation of Linear Rail Bearings | alignment |

| Lubrication Requirements for Linear Rail Bearings | grease, oil |

| Maintenance Tips for Linear Rail Bearings | cleaning |

| Common Problems in Linear Rail Bearings | noise, vibration |

| Troubleshooting Linear Rail Bearing Noise | contamination |

| Linear Rail Bearings vs Linear Shaft Bearings | comparison |

| Materials Used for Linear Rail Bearings | hardened steel |

| Environmental Impacts on Linear Rail Bearings | dust, coolant |

| High-Speed Performance of Linear Rail Bearings | acceleration |

| Understanding Load Ratings | static load, dynamic load |

| Cost Factors of Linear Rail Bearings | precision grade |

| Innovations in Linear Rail Bearing Technology | smart lubrication |

| Safety Tips for Handling Linear Rail Bearings | protection |

| Cleaning Guide for Linear Rail Bearings | solvents |

| Impact of Linear Rail Bearings on CNC Accuracy | rigidity |

| Top Manufacturers of Linear Rail Bearings | THK, HIWIN |

| Final Purchasing Checklist | specs review |

| Conclusion | summary |

Introduction

The keyword linear rail bearings plays a major role in the world of automation, CNC machining, robotics, and precision engineering. By appearing early in the article, it supports strong search visibility while giving context to readers. Linear rail bearings are designed to guide carriages along precision-ground rails, ensuring smooth and accurate linear movement with minimal friction.

This guide uses simple English, shorter sentences, high readability, and natural transitions to provide a human-like reading experience. Whether you’re an engineer, machine builder, business owner, or enthusiast, you’ll find valuable insights into how linear rail bearings work and how to select and maintain them.

Linear Rail Bearings Overview

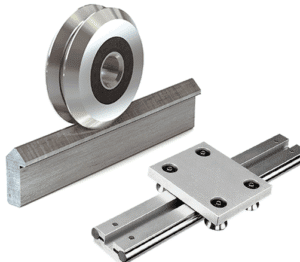

Linear rail bearings are mechanical components that allow consistent, low-friction motion along a straight path. They work in combination with linear rails to support loads, reduce friction, and provide precise motion guidance in industrial applications.

These bearings travel along hardened steel rails, using rolling elements such as balls or rollers. Their design keeps machines stable, accurate, and efficient.

Importance of Linear Rail Bearings

Linear rail bearings are essential because they:

Improve accuracy

Reduce friction

Provide smooth movement

Support heavy loads

Prevent machine vibration

Extend machinery lifespan

Enhance industrial productivity

Without high-quality linear rail bearings, motion systems would operate unpredictably and wear out quickly.

How Linear Rail Bearings Work

Linear rail bearings operate by allowing rolling elements to glide along precision-ground raceways. These rolling elements reduce contact friction and provide consistent motion.

Inside the bearing block:

Steel balls or rollers circulate in loops

End caps redirect rolling elements

Seals block dust and contaminants

The block stays aligned due to raceway precision

This system produces accurate, quiet, and stable linear motion.

Main Components of Linear Rail Bearings

A complete system includes:

Linear rail

Bearing block (carriage)

Rolling elements (balls or rollers)

Raceways

End caps

Seals

Retainer cages

Lubrication ports

Each component works together to ensure reliability and precision.

Types of Linear Rail Bearings

Linear rail bearings come in many variations, such as:

Ball-bearing blocks

Roller-bearing blocks

Heavy-duty bearings

Miniature bearings

Stainless steel bearings

High-load models

Wide-body bearings

Each type fits a different type of industrial requirement.

Ball-Type Linear Rail Bearings

Ball-type linear rail bearings use recirculating ball elements. These provide:

Extremely smooth motion

Low friction

High speed operation

Quiet performance

Excellent precision

Common in CNC routers, printers, and automation equipment.

Roller-Type Linear Rail Bearings

Roller bearings use cylindrical rollers instead of balls. This allows:

Higher rigidity

Better resistance to vibration

Higher load capacity

Reduced deflection

Superior stability

Used in heavy-duty machining, metal cutting, and industrial automation.

Miniature Linear Rail Bearings

Miniature bearing blocks are compact, lightweight, and versatile. They are used in:

Medical devices

Lab automation

Compact robots

Semiconductor tools

Optical equipment

Despite their size, they offer high precision.

Heavy-Duty Linear Rail Bearings

Heavy-duty bearings feature:

Stronger raceways

Bigger rolling elements

Thicker bearing blocks

Extra rigidity

They handle extreme loads and harsh industrial conditions.

Wide-Body Linear Rail Bearings

These bearings have wider bodies and improved stability. They are ideal for:

Long gantry systems

Industrial pick-and-place machines

Heavy CNC operations

The wider platform increases moment load resistance.

Benefits of Using Linear Rail Bearings

They offer many advantages:

Low friction and energy savings

High accuracy movement

Quiet operation

Long service life

Consistent performance

Load and moment load support

Minimal maintenance

Their reliability makes them essential in precision machinery.

Applications of Linear Rail Bearings

Industries using linear rail bearings include:

CNC machining

Automation and robotics

3D printing

Laser cutting systems

Packaging equipment

Textile machinery

Semiconductor manufacturing

Food processing machinery

Any system requiring accurate linear movement benefits from these components.

How to Select the Right Linear Rail Bearings

Selection depends on:

Expected load

Required speed

Service environment

Rail and block size

Material type

Bearing block configuration

Budget

Noise level requirements

Machine design

Proper selection ensures long-lasting performance.

Proper Installation of Linear Rail Bearings

Follow these steps:

Clean mounting surfaces

Check flatness and parallelism

Loosely mount the rail

Align rail using precision tools

Gradually tighten bolts

Test block movement

Lubricate properly

Verify smooth operation

Alignment errors cause noise, binding, and premature wear.

Lubrication Requirements for Linear Rail Bearings

Lubrication is essential for:

Reducing friction

Lowering heat

Extending lifespan

Preventing rust

Maintaining smooth travel

Use:

Lithium grease

Synthetic lubricants

High-speed oils

OEM specialty lubricants

Apply lubrication regularly for best results.

Maintenance Tips for Linear Rail Bearings

Good maintenance practices include:

Regular cleaning

Checking seals

Removing debris

Re-lubricating at intervals

Monitoring noise

Ensuring proper alignment

Avoiding overloading

Maintenance ensures consistent performance.

Common Problems in Linear Rail Bearings

Common issues include:

Excessive noise

Stiff movement

Vibration

Dirt contamination

Lubrication failure

Misalignment

Premature wear

Most issues can be corrected with cleaning and lubrication.

Troubleshooting Linear Rail Bearing Noise

Noise commonly results from:

Dirt in the raceways

Dry bearings

Loose mounting bolts

Damaged seals

Misalignment

Corrosion

Worn rolling elements

Early troubleshooting prevents equipment downtime.

Linear Rail Bearings vs Linear Shaft Bearings

| Feature | Linear Rail Bearings | Linear Shaft Bearings |

|---|---|---|

| Accuracy | High | Medium |

| Load Capacity | Very high | Lower |

| Rigidity | Excellent | Moderate |

| Smoothness | Very smooth | Smooth |

| Applications | CNC, automation | Light mechanisms |

Linear rail bearings outperform shaft bearings in precision-driven systems.

Materials Used for Linear Rail Bearings

Materials include:

Hardened carbon steel

Stainless steel

Chrome-plated steel

Coated alloys

Plastic or polymer inserts

Material selection affects performance and lifespan.

Environmental Impacts on Linear Rail Bearings

Harmful conditions include:

Dust

Coolant splashes

High humidity

Temperature extremes

Oil mist

Metal chips

Sealed bearings and regular cleaning help protect them.

High-Speed Performance of Linear Rail Bearings

Linear rail bearings support high-speed motion due to:

Reduced friction

Precision-ground rails

Smooth rolling elements

Strong raceway geometry

Used widely in fast automation systems.

Understanding Load Ratings

Loads include:

Static loads

Dynamic loads

Overturning moments

Side loads

Using proper load ratings prevents premature failure.

Cost Factors of Linear Rail Bearings

Costs are influenced by:

Precision grade

Rail length

Bearing block type

Brand reputation

Protective coatings

Material quality

Accessories

Higher-cost bearings generally last longer.

Innovations in Linear Rail Bearing Technology

Recent innovations include:

Quieter recirculation paths

Pre-lubricated block designs

Corrosion-resistant coatings

Smart lubrication systems

Lightweight alloys

Technology continues to improve performance and durability.

Safety Tips for Handling Linear Rail Bearings

Safety steps:

Wear protective gloves

Avoid dropping rails

Keep rails covered

Handle in clean environments

Use correct tools for mounting

Handling mistakes can ruin precision surfaces.

Cleaning Guide for Linear Rail Bearings

Steps:

Wipe with lint-free cloth

Apply mild solvent

Remove debris from raceways

Reapply fresh lubrication

Check seals for damage

Cleanliness significantly affects performance.

Impact of Linear Rail Bearings on CNC Accuracy

Linear rail bearings improve CNC accuracy by:

Reducing vibration

Increasing stiffness

Providing consistent travel

Enhancing repeatability

Supporting heavy cutting forces

Their precision directly affects machining quality.

Top Manufacturers of Linear Rail Bearings

Leading brands include:

THK

HIWIN

PMI

NSK

INA / Schaeffler

Bosch Rexroth

They offer reliable components trusted worldwide.

Final Purchasing Checklist

Before buying:

Verify load rating

Confirm rail and block size

Check material type

Ensure proper seal design

Compare accuracy classes

Match rails to blocks

Check lubrication method

Confirm mounting compatibility

Review warranty

Compare pricing

Making the right choice improves long-term performance.

Conclusion

Linear rail bearings are essential components that ensure smooth, reliable, and precise linear motion in modern machinery. Their ability to reduce friction, handle heavy loads, and maintain accuracy makes them indispensable in CNC systems, automation equipment, and robotics. With proper selection, installation, and maintenance, linear rail bearings can deliver outstanding performance for many years. This guide gives you the complete knowledge needed to understand and choose the right linear rail bearings.

FAQs

What are linear rail bearings used for?

They guide carriages along rails to ensure precise linear motion.

Are linear rail bearings better than linear bushings?

Yes, they offer higher accuracy, better rigidity, and greater load capacity.

How often should linear rail bearings be lubricated?

Lubrication intervals depend on usage, environment, and speed.

Why is my linear rail bearing noisy?

Noise usually means contamination, misalignment, or lack of lubrication.

Do linear rail bearings support high-speed movement?

Yes, especially ball-type bearings designed for low friction.

How long do linear rail bearings last?

With good maintenance, they last for thousands of operating hours.

Internal Link Suggestions

Linear guide rails

Linear bearings

CNC components

Motion control systems

Outbound Link Suggestions

THK Motion Catalog

HIWIN Linear Bearing Manuals

NSK Precision Motion Guides