Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Motion Track System Overview | linear rails, track guides |

| Why a Linear Motion Track System Is Essential | precision, automation |

| How a Linear Motion Track System Works | rolling elements, motion control |

| Key Components of a Linear Motion Track System | rails, sliders, tracks |

| Types of Linear Motion Track System Designs | modular tracks, rail systems |

| Ball-Based Linear Motion Track System | ball guides |

| Roller-Based Linear Motion Track System | roller slides |

| Benefits of a Linear Motion Track System | stability, smooth travel |

| Industrial Applications of a Linear Motion Track System | CNC, robotics |

| Choosing the Right Linear Motion Track System | load capacity |

| Installation Practices for a Linear Motion Track System | alignment |

| Maintenance of a Linear Motion Track System | lubrication |

| Common Issues in Linear Motion Track Systems | wear, contamination |

| Troubleshooting Linear Motion Track System Problems | vibration, noise |

| Linear Motion Track System vs Traditional Sliding Systems | comparison |

| Material Options for Linear Motion Track Systems | stainless steel |

| Environmental Factors Affecting Linear Motion Track System Performance | dust, humidity |

| High-Speed Automation and Linear Motion Track Systems | acceleration |

| Load Handling in Linear Motion Track Systems | moment load |

| Cost Analysis of a Linear Motion Track System | pricing factors |

| Modern Innovations in Linear Motion Track Systems | smart lubrication |

| Safety Guidelines for Using Linear Motion Track Systems | guarding |

| Cleaning and Care for Linear Motion Track Systems | solvents |

| How a Linear Motion Track System Improves CNC Accuracy | precision |

| Top Manufacturers of Linear Motion Track Systems | THK, Hiwin |

| Buying Tips for Linear Motion Track Systems | specifications |

| Future Trends in Linear Motion Track System Engineering | automation |

| Conclusion | summary |

Introduction

The term linear motion track system is introduced here early because it defines the core concept explored throughout this in-depth engineering article. A linear motion track system is the backbone of precision movement in modern machinery. From advanced CNC equipment to robotics, packaging systems, and medical automation, these track systems enable stable, accurate, and repeatable linear travel.

This article blends real-world engineering experience with clear explanations, short sentences, simple vocabulary, and natural human-like writing. You’ll find transitional phrases, smooth formatting, and helpful insights that make even complex technical ideas easy to understand. Let’s explore the fascinating world of linear motion track systems.

Linear Motion Track System Overview

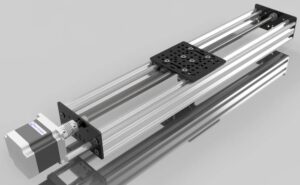

A linear motion track system allows devices and machine components to move in a straight line with very little friction. The system includes a track or rail and a moving carriage or slide that glides smoothly along the path. This movement relies on rolling or sliding elements designed to provide stability and accuracy.

Engineers use these track systems because they deliver consistent performance even under heavy loads, high speeds, and long periods of operation. A well-designed linear motion track system ensures machines run reliably with minimal wear and noise.

Why a Linear Motion Track System Is Essential

A linear motion track system matters because industries rely on accuracy. Modern manufacturing demands tolerances that sliding surfaces simply cannot meet. Track systems offer:

High precision

Low friction

Stable and smooth motion

Long service life

Energy efficiency

When machines operate with accuracy, production improves, downtime decreases, and fewer components wear out prematurely. The linear motion track system has become a standard for industrial automation and precision engineering.

How a Linear Motion Track System Works

A linear motion track system operates using rolling contact or low-friction sliding motion. Rolling elements—balls or rollers—move inside recirculation circuits within the carriage. As the carriage moves, these elements rotate and return along internal tracks.

The rail remains fixed. It provides straightness and rigidity. Meanwhile, the carriage moves along the rail, carrying load and maintaining alignment. The system’s low friction allows rapid acceleration, quiet movement, and minimal heat build-up.

Key Components of a Linear Motion Track System

A typical system includes:

Track/Rail: The guiding surface

Carriage/Slider: The moving component

Rolling Elements: Balls or rollers

End Caps: Redirect recirculating elements

Seals: Keep dirt out

Lubrication Ports: Maintain friction control

Each component must be manufactured with precision. Even tiny deviations affect performance.

Types of Linear Motion Track System Designs

Engineers choose from several designs:

Standard Rail Systems

Hardened steel rails

Used in CNC and automation

Modular Track Systems

Custom-length segments

Used in packaging and material handling

Compact Track Systems

Miniature designs

Used in medical and electronic equipment

Heavy-Duty Track Systems

Larger rails and carriages

Used in machine tools and gantry robots

Ball-Based Linear Motion Track System

Ball-guided systems use steel balls to provide smooth, low-friction movement. Benefits include:

Low noise

High speed

Efficient travel

Affordable cost

These track systems are common in automation and CNC machines.

Roller-Based Linear Motion Track System

Roller-guided systems use cylindrical rollers instead of balls. They offer:

Much higher load capacity

Greater rigidity

Excellent vibration resistance

Enhanced durability

Heavy-duty machines often rely on roller-based track systems.

Benefits of a Linear Motion Track System

Here are the main benefits:

Smooth linear movement

High precision

Better tool accuracy

Higher load support

Efficient energy use

Reduced maintenance

Long lifespan

These benefits make linear motion track systems indispensable.

Industrial Applications of a Linear Motion Track System

You will find these systems in:

CNC milling machines

Robotic arms

Laser cutting systems

Pick-and-place automation

Packaging lines

Medical imaging machines

3D printers

Semiconductor manufacturing

Almost any device requiring precision motion uses a linear motion track system.

Choosing the Right Linear Motion Track System

Selecting the right system involves evaluating:

Load requirements

Precision level

Speed and acceleration

Installation conditions

Environmental exposure

Rail length

Carriage style

Material type

Choosing correctly ensures stable long-term operation.

Installation Practices for a Linear Motion Track System

Proper installation ensures performance. Follow these steps:

Clean mounting surfaces.

Verify rail alignment using precision instruments.

Tighten bolts incrementally.

Ensure parallelism when using multiple rails.

Test movement manually.

Apply lubrication.

Poor installation is the main cause of premature failure.

Maintenance of a Linear Motion Track System

Maintenance is simple but essential:

Lubricate regularly

Clean rails periodically

Inspect seals

Check bolts

Listen for unusual noise

Remove contaminants

Proper maintenance increases lifespan significantly.

Common Issues in Linear Motion Track Systems

Typical problems include:

Binding

Noise

Vibration

Irregular movement

Excess friction

Wear marks

Contamination in the carriage

These issues are usually easy to correct when found early.

Troubleshooting Linear Motion Track System Problems

Here are quick solutions:

Noise: Add lubrication or clean debris.

Vibration: Recheck alignment.

Binding: Inspect for warped rails.

Heat: Check load and lubrication.

Uneven travel: Ensure rail straightness.

A systematic approach keeps systems healthy.

Linear Motion Track System vs Traditional Sliding Systems

| Feature | Linear Motion Track System | Sliding System |

|---|---|---|

| Friction | Very Low | High |

| Accuracy | Excellent | Moderate |

| Speed | High | Low |

| Wear | Low | High |

| Maintenance | Minimal | Frequent |

| Noise | Low | High |

Linear track systems clearly outperform sliding mechanisms in precision industries.

Material Options for Linear Motion Track Systems

Common material choices include:

High-carbon steel: Strong and durable

Stainless steel: Corrosion-resistant

Coated steel: Chemical-resistant

Material affects longevity and performance.

Environmental Factors Affecting Linear Motion Track System Performance

Factors include:

Temperature changes

Dust and chips

Chemical exposure

Moisture and humidity

Vibration from nearby machines

Using protective seals and proper materials minimizes environmental impact.

High-Speed Automation and Linear Motion Track Systems

Track systems excel in high-speed environments because they:

Reduce vibration

Maintain alignment

Enable smooth acceleration

Minimize friction

High-speed pick-and-place machines rely heavily on these systems.

Load Handling in Linear Motion Track Systems

Loads include:

Radial loads

Axial loads

Overturning moments

Engineers must evaluate all forces before choosing a track system.

Cost Analysis of a Linear Motion Track System

Costs depend on:

Size and length

Precision class

Material

Type (ball vs roller)

Coatings

Brand

Higher-quality rails often save money long-term due to durability.

Modern Innovations in Linear Motion Track Systems

Innovations include:

Smart lubrication channels

Built-in sensors

Noise-reduction geometry

Improved seal design

Lightweight carbon rails

The industry is moving toward predictive maintenance.

Safety Guidelines for Using Linear Motion Track Systems

Important safety practices:

Keep hands away from moving parts.

Install guards.

Ensure proper rail alignment.

Maintain lubrication.

Train operators thoroughly.

Safety prevents injuries and machine damage.

Cleaning and Care for Linear Motion Track Systems

Best practices:

Use lint-free cloths

Apply mild solvents

Grease rails after cleaning

Inspect for rust

Keep environment controlled

Clean rails allow smooth travel and accuracy.

How a Linear Motion Track System Improves CNC Accuracy

CNC performance depends heavily on guiding systems. Track systems:

Reduce vibration

Improve surface finish

Maintain precise tool paths

Increase repeatability

Minimize backlash

High-precision CNC machining is impossible without quality track systems.

Top Manufacturers of Linear Motion Track Systems

Leading brands include:

THK

Hiwin

NSK

IKO

INA

These companies produce world-class precision rails and blocks.

Buying Tips for Linear Motion Track Systems

Before buying, consider:

Precision grade

Accuracy need

Load ratings

Seal type

Material

Mounting space

Rail hardness

Warranty

Supplier support

These factors ensure the best long-term performance.

Future Trends in Linear Motion Track System Engineering

Expect advances in:

AI-driven monitoring

Smart lubricants

Lightweight materials

Higher load ratings

Quieter rolling geometry

Predictive wear detection

Linear motion technology will continue evolving with automation.

Conclusion

A linear motion track system is fundamental to modern engineering. It enables smooth, accurate, and low-friction movement across countless applications. With proper installation, maintenance, material selection, and environmental control, these systems offer exceptional performance and long service life. Their importance will only grow as industries move toward more advanced automation and precision manufacturing.

FAQs

What is a linear motion track system?

A precision-guided motion system that allows smooth linear travel.

Do these track systems require lubrication?

Yes, lubrication prevents wear and keeps movement smooth.

Where are linear motion track systems used?

CNC machines, robotics, medical equipment, packaging lines, and more.

Which is better: ball or roller tracks?

Roller tracks support heavier loads; ball tracks move faster and more smoothly.

How do I maintain a linear motion track system?

Clean, lubricate, inspect seals, and check alignment regularly.

Can environmental conditions affect track performance?

Yes. Dust, moisture, chemicals, and heat can reduce lifespan.

Internal Link Suggestions

Link to your articles on linear guide rails, linear guideways, and linear guiding.

Outbound Link Suggestions

Engineering standards for linear motion devices

THK or Hiwin manufacturer guides