Outline for “Linear Motion”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Motion | Historical perspective, Importance in modern engineering |

| Linear Motion | Definition, Core principles |

| Types of Linear Motion | Translational motion, Oscillatory motion, Uniform vs non-uniform |

| Linear Motion in Physics | Newton’s laws, Kinematics, Equations of motion |

| Key Components of Linear Motion Systems | Guide rails, Bearings, Actuators, Drive mechanisms |

| Linear Motion Mechanisms | Screw drives, Belt drives, Rack and pinion, Magnetic linear drives |

| Linear Motion Bearings | Ball bearings, Roller bearings, Plain bearings |

| Linear Motion Actuators | Electric actuators, Hydraulic actuators, Pneumatic actuators |

| Linear Motion Control Systems | Sensors, Controllers, Feedback mechanisms |

| Advantages of Linear Motion | Accuracy, Speed, Energy efficiency |

| Disadvantages of Linear Motion Systems | Cost, Maintenance, Space requirements |

| Linear Motion vs Rotary Motion | Differences, Applications, Efficiency |

| Applications of Linear Motion | CNC machines, Robotics, 3D printing, Medical devices |

| Linear Motion in CNC Machines | Precision cutting, Tool positioning |

| Linear Motion in Robotics | Automated arms, Pick-and-place systems |

| Linear Motion in Transportation | Maglev trains, Elevators, Conveyors |

| Linear Motion in Everyday Life | Sliding doors, Drawers, Household appliances |

| Design Considerations for Linear Motion Systems | Load capacity, Accuracy, Environment |

| Common Issues in Linear Motion Systems | Misalignment, Friction, Wear and tear |

| Troubleshooting Linear Motion Problems | Noise, Heat, Accuracy issues |

| Top Manufacturers of Linear Motion Systems | THK, Hiwin, NSK, Bosch Rexroth |

| Market Trends for Linear Motion 2025 | Automation growth, Smart manufacturing |

| Future of Linear Motion | IoT integration, AI-driven precision, Green technology |

| Environmental Impact of Linear Motion Systems | Energy usage, Sustainable materials |

| Linear Motion FAQs | Difference between linear and rotary?, Best actuator type?, How to reduce friction?, Can it handle heavy loads?, Average lifespan?, Where to buy? |

| Conclusion on Linear Motion | Importance, Final advice for industries and users |

Introduction to Linear Motion

Throughout history, movement has been at the heart of human progress. From the sliding blocks of ancient tools to the ultra-precise systems of today’s smart factories, linear motion has played an irreplaceable role. It’s not just about objects moving from one place to another—it’s about controlled, repeatable, and efficient motion that drives modern industries.

Linear Motion

Linear motion is defined as the movement of an object along a straight path, either in one direction or back and forth. Unlike rotary motion, which revolves around a central axis, linear motion is direct and predictable. This makes it essential for engineering, physics, robotics, and manufacturing.

Types of Linear Motion

Translational Motion: Straight-line motion in one direction.

Oscillatory Motion: Repeated back-and-forth linear movement.

Uniform Linear Motion: Constant velocity, no acceleration.

Non-uniform Linear Motion: Velocity changes due to acceleration or deceleration.

Linear Motion in Physics

In physics, linear motion is one of the most fundamental concepts. Governed by Newton’s laws, it explains how forces act on bodies moving in straight paths. Key equations like s = ut + ½at² and v = u + at help predict displacement and velocity.

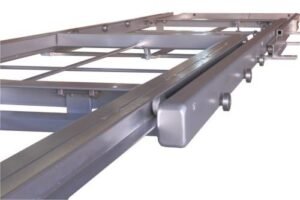

Key Components of Linear Motion Systems

Guide Rails: Ensure precise directional control.

Bearings: Reduce friction and allow smooth motion.

Actuators: Provide force to move the load.

Drive Mechanisms: Transfer power from motors to movement.

Linear Motion Mechanisms

Screw Drives (Ball/Lead Screws): High accuracy, often used in CNC machines.

Belt Drives: Fast, less precise, common in printers.

Rack and Pinion: Strong and durable, good for heavy-duty applications.

Magnetic Linear Drives: Contactless motion, reducing wear.

Linear Motion Bearings

Bearings are vital in reducing friction:

Ball Bearings: For smooth, high-speed applications.

Roller Bearings: Handle heavier loads.

Plain Bearings: Simple, cost-effective, but less precise.

Linear Motion Actuators

Electric Actuators: Precise, energy-efficient, widely used.

Hydraulic Actuators: Powerful, suited for heavy loads.

Pneumatic Actuators: Fast and simple, ideal for repetitive tasks.

Linear Motion Control Systems

Control systems regulate accuracy and efficiency using:

Sensors to track position.

Controllers to process commands.

Feedback mechanisms to correct errors in real time.

Advantages of Linear Motion

High precision

Fast response time

Low friction losses

Wide range of industrial uses

Disadvantages of Linear Motion Systems

High installation costs

Requires regular maintenance

Sensitive to environmental conditions like dust and moisture

Linear Motion vs Rotary Motion

Linear Motion: Moves in a straight line, suited for CNC, robotics, conveyors.

Rotary Motion: Circular movement, found in motors, fans, wheels.

Efficiency depends on the application—linear motion excels in precision, rotary in continuous motion.

Applications of Linear Motion

Robotics for automation and pick-and-place tasks

3D printers for accurate layer placement

Medical devices like MRI and CT scanners

Linear Motion in CNC Machines

Linear guide rails and ball screws enable CNC tools to move precisely along multiple axes. This ensures accuracy and repeatability in industries like aerospace and automotive manufacturing.

Linear Motion in Robotics

Robots rely on linear actuators and rails to move arms, grippers, and payloads smoothly. High-speed pick-and-place robots depend heavily on linear motion systems.

Linear Motion in Transportation

From maglev trains that float using magnetic linear drives to everyday elevators and escalators, linear motion technology powers modern mobility.

Linear Motion in Everyday Life

Sliding doors, drawers, printers, and even the mechanism in a washing machine drum all rely on simple linear motion principles.

Design Considerations for Linear Motion Systems

Required load capacity

Desired accuracy and speed

Environmental conditions (dust, temperature, humidity)

Maintenance accessibility

Common Issues in Linear Motion Systems

Misalignment causing uneven wear

Excessive friction leading to heat

Contamination from dust and particles

Insufficient lubrication

Troubleshooting Linear Motion Problems

Noise: Check for lubrication or bearing wear.

Heat: Inspect for friction or misalignment.

Accuracy Issues: Ensure calibration and alignment.

Top Manufacturers of Linear Motion Systems

THK – Leader in precision linear guides.

Hiwin – Known for affordability and versatility.

NSK – Japanese engineering excellence.

Bosch Rexroth – Industrial-grade reliability.

Market Trends for Linear Motion 2025

Automation, robotics, and electric vehicles are driving demand for high-precision linear motion systems. Smart sensors and IoT integration are enabling predictive maintenance.

Future of Linear Motion

Expect AI-driven predictive systems, self-lubricating bearings, and eco-friendly materials to shape the next generation of linear motion solutions.

Environmental Impact of Linear Motion Systems

Linear motion systems consume less energy compared to older friction-heavy designs. Manufacturers are now moving toward recyclable materials and biodegradable lubricants.

Linear Motion FAQs

What is the difference between linear and rotary motion?

Linear motion moves in a straight path, while rotary revolves around an axis.

Which type of actuator is best for linear motion?

Electric actuators are best for precision, while hydraulics suit heavy loads.

How can friction be reduced in linear motion?

Using bearings, proper lubrication, and alignment helps minimize friction.

Can linear motion handle heavy loads?

Yes, roller-bearing and hydraulic systems can support extremely heavy loads.

What is the average lifespan of a linear motion system?

With proper maintenance, they can last over 10 years.

Where can I buy linear motion components?

Reputable suppliers include Hiwin, THK, NSK, and Bosch Rexroth distributors.

Conclusion on Linear Motion

Linear motion is more than just a concept—it’s the backbone of modern industry. Whether in CNC machining, robotics, transportation, or daily appliances, it ensures precision, efficiency, and progress. With future innovations leaning towards smart and sustainable solutions, linear motion will remain a driving force in engineering.