Outline for “Linear Guide Rail”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Guide Rail | Importance in precision engineering, Common applications in industries |

| Linear Guide Rail | Definition, Basic working principle |

| Types of Linear Guide Rails | Profile rail, Round rail, Miniature linear guides, Roller vs ball bearing systems |

| Key Components of a Linear Guide Rail | Rail, Carriage, Bearings, Seals, Lubrication system |

| How Linear Guide Rails Work | Load distribution, Friction reduction, Motion accuracy |

| Advantages of Using Linear Guide Rail | High precision, Load-bearing capacity, Durability, Speed efficiency |

| Disadvantages of Linear Guide Rail | Cost factors, Maintenance needs, Installation challenges |

| Comparison with Other Motion Systems | Linear bushings vs linear guide rails, Belt drives vs guide rails |

| Material Selection for Linear Guide Rail | Stainless steel, Hardened steel, Aluminum |

| Design Considerations | Load capacity, Stroke length, Environmental conditions |

| Common Applications of Linear Guide Rail | CNC machines, 3D printers, Robotics, Medical equipment |

| Linear Guide Rail in CNC Machines | Precision cutting, Vibration control |

| Linear Guide Rail in Robotics | Smooth arm movement, Compact automation |

| Maintenance of Linear Guide Rail | Cleaning, Lubrication schedules, Replacement parts |

| Signs of Wear and Tear in Linear Guide Rail | Noise, Vibration, Reduced accuracy |

| Installation of Linear Guide Rail | Mounting process, Alignment techniques |

| Troubleshooting Linear Guide Rail Issues | Noise problems, Misalignment, Friction issues |

| Choosing the Right Linear Guide Rail | Industry-specific requirements, Budget vs performance |

| Top Brands for Linear Guide Rail | THK, Hiwin, NSK, Bosch Rexroth |

| Linear Guide Rail Market Trends 2025 | Growth in automation, Smart manufacturing integration |

| Cost Analysis of Linear Guide Rail | Pricing factors, Long-term investment value |

| Future Innovations in Linear Guide Rail | IoT-enabled monitoring, Self-lubricating systems |

| Environmental Impact of Linear Guide Rail | Energy efficiency, Eco-friendly materials |

| Linear Guide Rail FAQs | Best type for CNC?, How to maintain?, Common lifespan?, Can it handle heavy loads?, What affects accuracy?, Where to buy? |

| Conclusion on Linear Guide Rail | Importance for modern industry, Final advice for buyers |

Introduction to Linear Guide Rail

In the modern era of engineering and manufacturing, linear guide rail technology has become a cornerstone for machines requiring accuracy, durability, and smooth motion. From CNC machines carving intricate metal parts to medical devices requiring microscopic precision, these rails ensure efficiency. Their ability to reduce friction while supporting heavy loads makes them indispensable in high-demand industries.

Linear Guide Rail

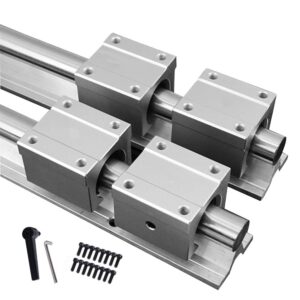

A linear guide rail is a precision mechanical component designed to provide smooth linear motion with minimal resistance. It typically consists of a rail and a carriage, supported by ball or roller bearings. Unlike simple sliding mechanisms, linear guide rails allow controlled, friction-reduced movement, making them ideal for machines requiring high accuracy.

Types of Linear Guide Rails

Profile Rail Guides – Offer high rigidity and precision, widely used in CNC machines.

Round Rail Guides – Easier to install, suitable for applications with misalignment issues.

Miniature Linear Guides – Compact, lightweight, perfect for electronics and small robotics.

Roller vs Ball Bearing Systems – Roller bearings handle heavier loads, while ball bearings are better for speed and precision.

Key Components of a Linear Guide Rail

Rail: The foundation, usually made of hardened steel.

Carriage (Block): Moves along the rail, carrying loads.

Bearings: Reduce friction and ensure smooth movement.

Seals: Protect against dust and debris.

Lubrication System: Ensures long-term performance.

How Linear Guide Rails Work

Linear guide rails distribute loads through rolling elements like balls or rollers, which circulate inside the carriage. This reduces friction drastically, compared to sliding systems, allowing smooth, precise, and repeatable movement.

Advantages of Using Linear Guide Rail

High precision and repeatability

Long service life with proper care

Handles both radial and axial loads

Reduced energy consumption due to low friction

Disadvantages of Linear Guide Rail

Higher initial cost than traditional motion systems

Requires regular lubrication and maintenance

Sensitive to misalignment during installation

Comparison with Other Motion Systems

Linear bushings may be cheaper but lack precision. Belt-driven systems are faster but less accurate. Linear guide rails strike a balance, offering accuracy, durability, and reliability.

Material Selection for Linear Guide Rail

Stainless Steel: Best for corrosion resistance.

Hardened Steel: Provides strength and durability.

Aluminum: Lightweight, but less durable for heavy-duty tasks.

Design Considerations

Choosing the right rail requires considering load requirements, expected lifespan, speed, environmental exposure (dust, moisture), and installation conditions.

Common Applications of Linear Guide Rail

CNC machines

Industrial automation

Robotics arms

3D printers

Semiconductor equipment

Medical imaging machines

Linear Guide Rail in CNC Machines

CNC machining demands accuracy down to microns. Linear guide rails ensure vibration-free, precise tool movement, essential for industries like aerospace and automotive.

Linear Guide Rail in Robotics

In robotics, rails enable controlled motion for arms, end-effectors, and gantry systems. Compact rails enhance performance in collaborative robots.

Maintenance of Linear Guide Rail

Proper care extends service life. Periodic lubrication, cleaning, and seal replacement are essential. Ignoring maintenance can lead to costly downtime.

Signs of Wear and Tear in Linear Guide Rail

Unusual noise

Vibrations

Decreased accuracy

Increased resistance during movement

Installation of Linear Guide Rail

Accurate alignment ensures performance. Shims may be required to adjust flatness. Torque control is critical during mounting.

Troubleshooting Linear Guide Rail Issues

Noise Issues: Caused by poor lubrication.

Misalignment: Results in uneven wear.

Friction Problems: Indicate contamination or seal damage.

Choosing the Right Linear Guide Rail

Evaluate based on required precision, load capacity, environmental conditions, and budget. For high-precision industries, profile rails are recommended.

Top Brands for Linear Guide Rail

THK – Known for reliability and performance.

Hiwin – Affordable, versatile options.

NSK – Japanese precision engineering.

Bosch Rexroth – Industrial-grade durability.

Linear Guide Rail Market Trends 2025

With automation booming, demand for high-performance rails is rising. Smart factories now integrate IoT-enabled monitoring for predictive maintenance.

Cost Analysis of Linear Guide Rail

Prices vary based on size, brand, and load capacity. While initial investment may be high, long-term efficiency and reduced downtime outweigh the cost.

Future Innovations in Linear Guide Rail

IoT-based smart monitoring

Self-lubricating systems

Lightweight composite materials

Eco-friendly lubrication solutions

Environmental Impact of Linear Guide Rail

Eco-friendly designs aim to reduce energy loss, and recyclable materials are now being introduced for sustainability.

Linear Guide Rail FAQs

What is the best type of linear guide rail for CNC machines?

Profile rail guides are best due to their rigidity and precision.

How often should linear guide rails be lubricated?

Depending on use, lubrication is required every 3–6 months.

What is the average lifespan of a linear guide rail?

With proper maintenance, they can last over 10 years.

Can linear guide rails handle heavy loads?

Yes, roller-bearing linear guides can support extremely high loads.

What factors affect linear guide rail accuracy?

Misalignment, wear, and contamination affect accuracy.

Where can I buy linear guide rails?

Top suppliers include Hiwin, THK, Bosch Rexroth, and NSK distributors.

Conclusion on Linear Guide Rail

The linear guide rail remains one of the most vital components in modern precision engineering. Its ability to provide smooth, accurate motion while supporting heavy loads makes it an indispensable choice for industries ranging from aerospace to robotics. With proper selection, installation, and maintenance, it becomes not just a component but a long-term investment in performance.