Outline for Long-Form Article on “Linear Bearing”

| Section | Sub-Section |

|---|---|

| Introduction | Importance of linear bearings in modern machinery |

| Linear Bearing | What is a linear bearing? |

| History of Linear Bearings | From sliding friction to rolling motion |

| Core Components of Linear Bearings | Shaft, housing, rolling elements |

| Types of Linear Bearings | Ball, roller, plain, and hybrid |

| Ball Linear Bearing | Smooth operation for high-speed systems |

| Roller Linear Bearing | Heavy load and high rigidity |

| Plain Linear Bearing | Simple, cost-effective designs |

| Hybrid Linear Bearing | Combination of different mechanisms |

| How Linear Bearings Work | Replacing sliding with rolling friction |

| Linear Bearing vs Linear Guide Rail | Key differences and performance factors |

| Applications of Linear Bearings | CNC, robotics, medical, aerospace, 3D printing |

| Linear Bearing in CNC Machines | Ensuring high precision and rigidity |

| Linear Bearing in Robotics | Smooth and controlled automation |

| Linear Bearing in 3D Printers | Improving accuracy and stability |

| Linear Bearing in Medical Devices | Imaging, surgical equipment, and lab instruments |

| Materials Used in Linear Bearings | Steel, ceramics, and polymers |

| Surface Treatments in Bearings | Coatings for wear and corrosion resistance |

| Lubrication and Maintenance | Ensuring smooth operation and long life |

| Common Linear Bearing Problems | Misalignment, wear, contamination |

| Installation Best Practices | Mounting and alignment techniques |

| Advantages of Linear Bearings | Accuracy, smoothness, load capacity |

| Disadvantages of Linear Bearings | Cost, contamination sensitivity |

| How to Select Linear Bearings | Factors to consider before buying |

| Top Manufacturers of Linear Bearings | THK, NSK, Hiwin, SKF, Bosch Rexroth |

| Future of Linear Bearings | Smart bearings and IoT integration |

| Sustainability in Linear Bearings | Eco-friendly materials and lubricants |

| FAQs on Linear Bearings | Common buyer concerns answered |

| Conclusion | Final insights on the role of linear bearings |

| Inbound & Outbound Links Suggestions | SEO linking strategies |

Introduction

In modern machinery and automation, linear bearings are crucial components that enable smooth, precise, and efficient motion along a straight path. Whether in CNC machines, robotics, aerospace systems, or medical devices, linear bearings play a vital role in reducing friction, improving accuracy, and extending machine life.

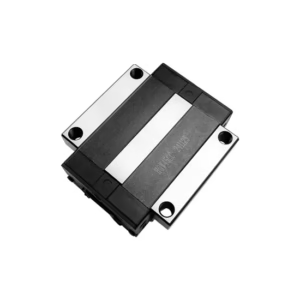

Linear Bearing

A linear bearing is a mechanical device designed to provide free motion in a single direction. Unlike conventional sliding surfaces, linear bearings use rolling elements such as balls or rollers to minimize friction. This makes them indispensable in applications requiring precision, repeatability, and durability.

History of Linear Bearings

Linear bearings trace their roots back to simple sliding mechanisms that relied on lubrication to reduce friction. Over time, engineers discovered the advantages of rolling elements, leading to the development of ball and roller-based designs. Today, linear bearings are manufactured with high-performance materials and coatings to meet the demands of advanced industries.

Core Components of Linear Bearings

A linear bearing typically consists of:

- Shaft or Rail: Provides the linear path.

- Bearing Housing: Holds the rolling elements in place.

- Rolling Elements: Balls or rollers that reduce friction.

- End Seals: Protect against contamination and retain lubrication.

Types of Linear Bearings

Different types of linear bearings are suited for different applications:

- Ball Linear Bearings – High speed and smooth motion.

- Roller Linear Bearings – Strong and rigid for heavy loads.

- Plain Linear Bearings – Simple, low-cost, and low-maintenance.

- Hybrid Linear Bearings – Combine strengths of multiple types.

Ball Linear Bearing

Ball linear bearings use recirculating balls to achieve smooth, low-friction motion. They are widely used in CNC machines and 3D printers where precision and repeatability are essential.

Roller Linear Bearing

Roller bearings use cylindrical rollers instead of balls, distributing loads over larger areas. This makes them suitable for heavy-duty applications such as factory automation and machining centers.

Plain Linear Bearing

These bearings rely on sliding contact and are often made of self-lubricating materials like bronze or polymers. They are ideal for dusty or dirty environments where ball or roller bearings might fail.

Hybrid Linear Bearing

Hybrid bearings combine the best of ball, roller, or plain mechanisms, offering versatility for specialized applications.

How Linear Bearings Work

Linear bearings reduce resistance by converting sliding friction into rolling friction. Rolling elements inside the bearing housing transfer loads smoothly along the shaft or rail, minimizing energy loss and wear.

Linear Bearing vs Linear Guide Rail

While both facilitate linear motion, linear bearings usually slide on shafts, whereas linear guide rails use profiled tracks for higher rigidity and precision. Bearings are better for compact, flexible applications, while rails dominate in heavy-duty, high-accuracy environments.

Applications of Linear Bearings

- CNC Machines: Cutting, drilling, and milling precision.

- Robotics: Smooth and accurate arm movement.

- 3D Printing: Ensuring accurate print head positioning.

- Medical Devices: Imaging machines and surgical robots.

- Aerospace: High-performance automation systems.

Linear Bearing in CNC Machines

Linear bearings enable CNC machines to achieve micron-level accuracy. By reducing vibration and maintaining rigidity, they ensure repeatable, high-precision machining operations.

Linear Bearing in Robotics

In robotics, bearings allow precise and controlled linear movements. They ensure smooth operation in robotic arms used in manufacturing, packaging, and even surgery.

Linear Bearing in 3D Printers

Linear bearings improve 3D printing accuracy by stabilizing the motion of print heads, reducing errors, and enhancing print quality.

Linear Bearing in Medical Devices

From MRI scanners to surgical robots, linear bearings are critical in the medical industry. Their precision and reliability ensure smooth, controlled movement in delicate operations.

Materials Used in Linear Bearings

- Carbon Steel: Affordable and strong.

- Stainless Steel: Resistant to corrosion.

- Ceramics: Lightweight and non-magnetic.

- Polymers: Self-lubricating and cost-effective.

Surface Treatments in Bearings

Modern bearings often include surface treatments such as nitriding, chrome plating, or Teflon coatings to improve wear resistance and reduce friction.

Lubrication and Maintenance

Regular lubrication is key to maintaining performance. Grease or oil lubrication systems reduce wear, prevent overheating, and extend bearing life.

Common Linear Bearing Problems

- Misalignment: Causes uneven wear.

- Contamination: Dust and debris disrupt smooth motion.

- Insufficient Lubrication: Leads to noise and premature failure.

Installation Best Practices

- Ensure proper shaft alignment.

- Use precision mounting techniques.

- Apply preload correctly.

- Keep components clean during installation.

Advantages of Linear Bearings

- High accuracy and repeatability.

- Smooth, low-friction movement.

- Long service life.

- Versatile across industries.

Disadvantages of Linear Bearings

- Sensitive to contamination.

- Higher cost than simple bushings.

- Require careful installation and maintenance.

How to Select Linear Bearings

Factors to consider include:

- Load capacity.

- Speed and precision requirements.

- Environmental conditions.

- Maintenance needs and budget.

Top Manufacturers of Linear Bearings

- THK – Global leader in motion systems.

- NSK – Known for reliability.

- Hiwin – Affordable and widely used.

- SKF – Strong reputation in engineering.

- Bosch Rexroth – Renowned for automation solutions.

Future of Linear Bearings

IoT-enabled smart linear bearings are the future, with sensors monitoring wear, lubrication levels, and performance in real time. Predictive maintenance will reduce downtime and improve efficiency.

Sustainability in Linear Bearings

Manufacturers are moving towards recyclable materials, eco-friendly lubricants, and energy-efficient designs to reduce environmental impact.

FAQs on Linear Bearings

What is a linear bearing used for?

It enables smooth, precise linear motion in machinery like CNCs, robots, and 3D printers.

Do linear bearings need lubrication?

Yes, lubrication is essential to minimize wear and extend life.

How long do linear bearings last?

With proper maintenance, they can last for years under heavy use.

What’s the difference between linear bearings and guide rails?

Bearings slide on shafts, while rails provide higher rigidity and accuracy.

Are linear bearings expensive?

They cost more than plain bushings but offer long-term savings.

Can linear bearings handle heavy loads?

Yes, roller-type bearings are designed for high-load applications.

Conclusion

Linear bearings are the foundation of smooth and accurate motion in today’s industries. Their versatility, precision, and durability make them indispensable in CNC machines, robotics, medical devices, and more. While they require careful installation and maintenance, their benefits far outweigh the drawbacks, ensuring reliable performance in critical applications.

Inbound and Outbound Links Suggestions

Inbound Links:

- Guide on CNC machining.

- Robotics automation article.

- Maintenance and lubrication best practices.

Outbound Links: