Outline for Long-Form Article on “Linear Rails”

| Section | Sub-Section |

|---|---|

| Introduction | Importance of linear rails in engineering |

| Linear Rails | What are linear rails? |

| History of Linear Motion Technology | From sliding systems to precision rails |

| Core Components of Linear Rails | Rail, carriage, rolling elements |

| Types of Linear Rails | Profiled, round, miniature, heavy-duty |

| Profiled Linear Rails | High precision and rigidity |

| Round Linear Rails | Flexible and easy installation |

| Miniature Linear Rails | Compact size for electronics and medical use |

| Heavy-Duty Linear Rails | Designed for industrial-scale loads |

| Ball Linear Rails | Recirculating ball systems |

| Roller Linear Rails | Designed for load stability |

| How Linear Rails Work | Motion principle explained |

| Linear Rails vs Linear Shafts | Design, performance, and applications |

| Applications of Linear Rails | CNC, robotics, automation, aerospace |

| Linear Rails in CNC Machines | Ensuring accuracy in machining |

| Linear Rails in Robotics | Smooth and controlled movement |

| Linear Rails in 3D Printing | Improving print quality |

| Linear Rails in Medical Devices | Precision for imaging and surgical equipment |

| Materials Used in Linear Rails | Steel, ceramics, polymers |

| Surface Treatments for Linear Rails | Coatings for durability and corrosion resistance |

| Lubrication and Maintenance | Extending service life |

| Common Problems with Linear Rails | Misalignment, wear, contamination |

| Installation Best Practices | Alignment, preload, mounting methods |

| Advantages of Linear Rails | Accuracy, smoothness, durability |

| Disadvantages of Linear Rails | Cost, contamination sensitivity |

| How to Choose Linear Rails | Factors for selection |

| Top Brands in Linear Rails Market | THK, NSK, Hiwin, SKF, Bosch Rexroth |

| Future of Linear Rails | Smart rails and IoT integration |

| Sustainability in Linear Rails | Eco-friendly innovations |

| FAQs on Linear Rails | Answering common concerns |

| Conclusion | Final thoughts on the role of linear rails |

| Inbound & Outbound Links Suggestions | SEO linking strategies |

Introduction

In today’s era of precision machinery and robotics, linear rails have become an indispensable component of automation. These rails allow smooth, accurate, and controlled linear motion, making them essential in CNC machines, 3D printers, and medical devices. Their ability to reduce friction, enhance rigidity, and support heavy loads has revolutionized engineering and manufacturing industries.

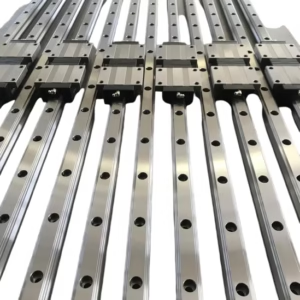

Linear Rails

Linear rails are mechanical motion systems that guide moving parts in a straight path with minimal friction. They typically consist of a rail and a carriage (block) that houses rolling elements such as balls or rollers. The carriage slides along the rail, ensuring stability, accuracy, and repeatability.

History of Linear Motion Technology

Before linear rails, machines relied on sliding motion systems that caused high friction and wear. With advancements in ball and roller bearings, linear motion systems evolved into precise, low-friction rail designs. Today, linear rails combine high-grade steel, advanced coatings, and lubrication systems to achieve long service life and micron-level precision.

Core Components of Linear Rails

Rail: A hardened, precision-ground track.

Carriage (Block): Slides along the rail while housing rolling elements.

Rolling Elements: Balls or rollers that reduce friction.

End Caps and Seals: Retain lubrication and block contaminants.

Types of Linear Rails

Different designs suit different performance needs:

Profiled Linear Rails – High rigidity and precision.

Round Linear Rails – Flexible and cost-effective.

Miniature Linear Rails – Small and lightweight.

Heavy-Duty Linear Rails – For high-load applications.

Profiled Linear Rails

Profile rails feature rectangular shapes with optimized contact surfaces. They provide excellent rigidity, high load capacity, and precise guidance. Commonly used in CNC machining centers, they ensure vibration-free cutting.

Round Linear Rails

Round rails are easier to mount and align. They are less rigid than profiled rails but work well in applications where accuracy is less critical, such as packaging machines.

Miniature Linear Rails

Compact yet precise, miniature rails are used in electronics manufacturing, laboratory instruments, and medical devices. Their lightweight design allows smooth motion in small spaces.

Heavy-Duty Linear Rails

Built for strength, heavy-duty rails are designed for aerospace, automotive, and industrial automation, where large forces and high rigidity are required.

Ball Linear Rails

Ball-type rails use recirculating balls for smooth, low-friction motion. They are widely used in high-speed applications requiring accuracy.

Roller Linear Rails

Roller rails use cylindrical rollers instead of balls. This design distributes loads more evenly, providing greater stiffness and durability under heavy loads.

How Linear Rails Work

Linear rails function by replacing sliding friction with rolling friction. The rolling elements inside the carriage move smoothly as the carriage travels along the rail, reducing energy loss and wear.

Linear Rails vs Linear Shafts

While linear rails offer superior rigidity and load capacity, linear shafts are easier to install and more cost-effective. Shafts are used in lighter applications, while rails dominate high-precision industries.

Applications of Linear Rails

Linear rails serve a wide range of industries:

CNC Machines – Precision machining.

Robotics – Smooth and accurate motion.

3D Printing – Stable print head movement.

Medical Devices – Precision in imaging and surgical tools.

Aerospace & Automotive – Heavy-duty automation.

Linear Rails in CNC Machines

CNC machining relies on rails for accuracy. By preventing vibration and maintaining rigidity, rails enable precise cutting and milling operations.

Linear Rails in Robotics

Robotic arms use rails for stability and backlash-free operation, essential for industrial automation and assembly lines.

Linear Rails in 3D Printing

Linear rails ensure accuracy in material deposition, resulting in high-quality 3D prints with minimal defects.

Linear Rails in Medical Devices

In the medical industry, precision is critical. Rails enable smooth, reliable movement in MRI machines, surgical robots, and laboratory instruments.

Materials Used in Linear Rails

Carbon Steel: Strong and affordable.

Stainless Steel: Corrosion-resistant.

Ceramics: Lightweight, non-magnetic.

Polymers: Used in lightweight applications.

Surface Treatments for Linear Rails

Surface coatings like nitriding and chrome plating enhance wear resistance, reduce corrosion, and extend the lifespan of rails.

Lubrication and Maintenance

Rails require regular lubrication with oil or grease to reduce wear and maintain smooth operation. Seals and automatic lubrication systems further improve durability.

Common Problems with Linear Rails

Misalignment: Causes uneven load distribution.

Contamination: Dust or debris disrupts motion.

Insufficient Lubrication: Leads to wear and noise.

Installation Best Practices

Align rails precisely.

Use torque-controlled fasteners.

Apply correct preload settings.

Keep rails clean during installation.

Advantages of Linear Rails

High precision and rigidity.

Long service life.

Smooth, low-friction motion.

High load capacity.

Disadvantages of Linear Rails

More expensive than shafts.

Sensitive to dust and dirt.

Require careful installation.

How to Choose Linear Rails

Consider:

Load requirements.

Desired accuracy.

Speed of operation.

Environmental conditions.

Budget constraints.

Top Brands in Linear Rails Market

THK – Known for innovation.

NSK – Durable, high-quality systems.

Hiwin – Affordable and versatile.

SKF – Trusted global engineering brand.

Bosch Rexroth – Industry leader in automation.

Future of Linear Rails

Smart rails integrated with IoT and sensors will enable predictive maintenance, reducing downtime and improving efficiency.

Sustainability in Linear Rails

Manufacturers are developing recyclable designs, eco-friendly lubricants, and energy-efficient systems to meet sustainability goals.

FAQs on Linear Rails

What are linear rails used for?

They enable smooth, accurate motion in CNC machines, robotics, and automation systems.

Do linear rails need lubrication?

Yes, lubrication is essential for performance and durability.

Which is better: rails or shafts?

Rails offer more accuracy and load capacity, while shafts are simpler and cheaper.

How long do linear rails last?

With proper maintenance, they can last several years.

Are linear rails expensive?

They are costlier upfront but save money in the long run due to durability.

Can linear rails handle heavy loads?

Yes, roller and heavy-duty rails are designed for high-load applications.

Conclusion

Linear rails are at the heart of modern automation. Their precision, rigidity, and durability make them essential in industries ranging from CNC machining to medical devices. While they require proper care and installation, their long-term benefits make them one of the most valuable components in engineering today.

Inbound and Outbound Links Suggestions

Inbound Links:

CNC machining technology guide.

Robotics automation insights.

Maintenance and lubrication tips page.

Outbound Links: