Outline for Linear Bearing Guide

| Section | Subtopics |

|---|---|

| Introduction | Importance of linear bearings in modern engineering |

| Linear Bearing Guide | What is a linear bearing guide, role in precision motion |

| History of Linear Bearings | Origins, evolution, and industrial adoption |

| Types of Linear Bearing Guide | Ball bearing type, roller type, plain type |

| Core Components of Linear Bearing Guide | Rail, carriage, rolling elements, seals |

| Key Features of Linear Bearing Guide | Smooth motion, rigidity, long lifespan |

| How Linear Bearing Guide Works | Rolling vs sliding mechanics |

| Advantages of Linear Bearing Guide | Accuracy, durability, cost-effectiveness |

| Applications of Linear Bearing Guide | CNC, robotics, medical devices, 3D printing |

| Linear Bearing Guide in CNC Machines | High-precision machining benefits |

| Linear Bearing Guide in Robotics | Smooth robotic arm motion |

| Linear Bearing Guide in Medical Equipment | Imaging and surgical systems |

| Installation of Linear Bearing Guide | Alignment, mounting, lubrication |

| Lubrication and Maintenance | Grease vs oil, schedules, best practices |

| Common Issues and Troubleshooting | Noise, misalignment, wear |

| Comparison with Other Motion Systems | Linear bearings vs bushings, vs rails |

| Choosing the Right Linear Bearing Guide | Load, speed, environment factors |

| Customizable Options | Coatings, preload, sizes |

| Linear Bearing Guide in Automation | Role in smart factories and Industry 4.0 |

| Economic Benefits of Linear Bearing Guide | ROI, reduced downtime |

| Sustainability and Environmental Impact | Efficiency, eco-friendly materials |

| Case Studies | Examples from CNC, robotics, and medical |

| Market Trends | Growth of automation and linear motion |

| Frequently Asked Questions | FAQs with answers |

| Conclusion | Final thoughts on linear bearing guide |

| Inbound and Outbound Link Suggestions | Suggested internal and external links |

Introduction

Precision is the lifeblood of modern engineering. Whether cutting metal with a CNC machine, printing with a 3D printer, or guiding robotic arms, accurate and smooth motion is essential. This is where the linear bearing guide becomes indispensable.

Acting as the foundation for countless motion systems, a linear bearing guide reduces friction, supports heavy loads, and ensures repeatable accuracy. Without them, industries like aerospace, robotics, and medicine would face costly inefficiencies.

This guide explores the world of linear bearing guides — what they are, how they work, their advantages, and their diverse applications.

Linear Bearing Guide

A linear bearing guide is a motion component designed to provide smooth, precise, and low-friction movement along a straight path. Unlike traditional sliding mechanisms that wear quickly, linear bearings use rolling elements such as steel balls or rollers, significantly reducing friction.

They are commonly paired with rails or shafts, ensuring that moving parts maintain alignment under load. The result is consistent, repeatable motion crucial in automation and manufacturing.

History of Linear Bearings

The concept of linear motion has existed for centuries, from early carts using wooden grooves to modern high-tech ball bearings. The industrial revolution introduced steel bearings, paving the way for today’s high-performance systems.

1900s: Introduction of rolling element bearings in machinery.

1950s: Development of precision ground linear shafts.

1980s–2000s: Explosion of CNC and robotics drove innovation in linear guides.

Today: Linear bearing guides are essential in industries demanding micrometer-level precision.

Types of Linear Bearing Guide

Different environments demand different bearing types. The three main categories are:

Ball Bearing Guides – High precision, smooth operation, widely used in CNC.

Roller Bearing Guides – Higher load capacity, suitable for heavy-duty tasks.

Plain Bearing Guides – Use sliding contact with low-maintenance polymers, ideal for dusty environments.

Each type balances precision, load capacity, and cost depending on the application.

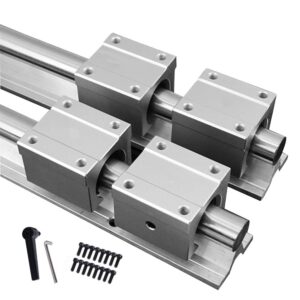

Core Components of Linear Bearing Guide

A typical linear bearing guide includes:

Guide Rail or Shaft – Hardened steel track for motion.

Carriage (Block) – The housing that moves along the rail.

Rolling Elements – Balls or rollers to minimize friction.

Seals and End Caps – Protect against dirt and contamination.

Lubrication System – Grease or oil channels to reduce wear.

These components work together to ensure smooth, long-lasting performance.

Key Features of Linear Bearing Guide

Engineers choose linear bearings because of their performance-oriented features:

High precision – Micrometer-level positioning.

Durability – Withstands years of operation.

High rigidity – Supports both radial and axial loads.

Smooth operation – Minimizes vibration and noise.

Interchangeability – Standardized designs allow easy replacement.

How Linear Bearing Guide Works

Linear bearing guides work by replacing sliding friction with rolling contact. Steel balls or rollers circulate inside the block as it moves along the rail. This reduces resistance and allows heavier loads with smoother travel.

The difference between rolling and sliding can be compared to pushing a box on the floor versus rolling it on wheels — one drags, the other glides.

Advantages of Linear Bearing Guide

The benefits of using linear bearings include:

Improved accuracy – Essential for CNC, robotics, and medical devices.

Energy efficiency – Less friction means less power needed.

Load capacity – Handles multi-directional forces.

Low maintenance – Requires only periodic lubrication.

Cost-effectiveness – Long-term savings due to durability.

Applications of Linear Bearing Guide

Linear bearing guides are everywhere in modern industries:

CNC Machines – Precision cutting, milling, and engraving.

Robotics – Smooth, controlled arm movements.

Medical Equipment – Quiet, accurate imaging systems.

3D Printing – Layer precision and fast movement.

Packaging Industry – High-speed, consistent automation.

Linear Bearing Guide in CNC Machines

CNC machines depend on linear bearings for tool stability. They ensure:

Reduced vibration during machining.

Higher cutting speeds without compromising accuracy.

Longer tool life due to smooth operation.

From milling to laser cutting, linear guides make CNC reliable and efficient.

Linear Bearing Guide in Robotics

In robotics, accuracy is crucial. Linear bearings allow:

Fast and precise arm positioning.

Energy-efficient movements.

Durability in high-speed automation lines.

They enable robots to assemble electronics or even assist in surgery with flawless precision.

Linear Bearing Guide in Medical Equipment

Medical devices require quiet and smooth motion. Linear bearings play a role in:

MRI and CT scanners

Robotic surgery systems

Hospital beds and imaging tables

Their reliability ensures patient safety and accurate diagnostics.

Installation of Linear Bearing Guide

Proper installation maximizes lifespan. Steps include:

Surface preparation – Ensure rails are mounted on clean, flat surfaces.

Rail alignment – Precision alignment is crucial.

Bolt tightening – Secure evenly to prevent distortion.

Block installation – Carefully slide carriage onto the rail.

Lubrication – Apply before initial use.

Lubrication and Maintenance

Lubrication keeps linear bearings running smoothly.

Light-duty use: Re-lubricate every 6 months.

Heavy-duty use: Every 1–3 months.

Best practice: Use manufacturer-recommended grease or oil.

Avoid over-lubrication, as excess grease can trap dust.

Common Issues and Troubleshooting

Some issues include:

Noise – Often due to lack of lubrication or dirt.

Vibration – Misalignment or rail damage.

Uneven wear – Contamination or incorrect preload.

Routine checks prevent costly breakdowns.

Comparison with Other Motion Systems

| Motion System | Pros | Cons |

|---|---|---|

| Linear Bearings | High precision, low friction | More expensive than bushings |

| Bushings | Low cost, simple | High friction, less accurate |

| Linear Rails | Extremely rigid, durable | Heavier, requires precise installation |

Linear bearings strike the right balance between performance and affordability.

Choosing the Right Linear Bearing Guide

Consider these factors:

Load requirements – Light, medium, or heavy-duty.

Speed – High-speed applications need low-friction designs.

Environment – Dusty or clean-room conditions.

Budget – Balance cost with performance.

Customizable Options

Manufacturers offer customization such as:

Special coatings for corrosion resistance.

Different preload levels for accuracy.

Compact designs for limited spaces.

High-speed variants for automation.

Linear Bearing Guide in Automation

Automation thrives on consistency, and linear bearings deliver just that. From packaging to logistics, they ensure:

Faster production cycles.

Reduced downtime.

Higher accuracy in repetitive tasks.

Economic Benefits of Linear Bearing Guide

Though initially more costly than bushings, they save money long-term by:

Reducing downtime.

Lowering maintenance costs.

Extending equipment lifespan.

Sustainability and Environmental Impact

Linear bearings enhance energy efficiency by reducing friction. Their long lifespan also means fewer replacements, contributing to sustainable engineering practices.

Case Studies

CNC Shop: Boosted production efficiency by 20% using linear bearings.

Medical Imaging Company: Reduced noise in MRI machines.

Electronics Manufacturer: Improved robotic assembly accuracy.

Market Trends

The linear motion market is growing due to:

Rising demand for automation.

Growth of CNC and robotics.

Advances in medical technology.

Linear bearings are at the center of this expansion.

Frequently Asked Questions

What is a linear bearing guide used for?

It is used for precise and low-friction linear motion in CNC, robotics, and medical devices.

Are linear bearings better than bushings?

Yes, they offer smoother and more accurate motion, though they cost more.

Do linear bearings need lubrication?

Yes, lubrication is essential for smooth performance and durability.

How long do linear bearings last?

With proper care, they can last for years under heavy use.

Can linear bearings handle heavy loads?

Yes, roller-type bearings are designed for high load capacity.

What industries use linear bearings?

Industries such as aerospace, electronics, automotive, and healthcare.

Conclusion

The linear bearing guide is a critical component in modern motion systems. By combining precision, durability, and efficiency, it enables industries to achieve reliable and cost-effective performance. From CNC machining to medical imaging, linear bearings provide the foundation for smooth and accurate motion.

As automation continues to evolve, linear bearings will remain at the forefront of innovation, ensuring industries move forward with speed, precision, and confidence.

Inbound and Outbound Link Suggestions

Inbound Links (if publishing on a website):

CNC Machine Guide

Robotics and Automation Solutions

Motion Control Components

Industrial Bearings Overview

Outbound Links: