Outline for “Linear Guide Bearings”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Guide Bearings | Definition, Importance in Precision Engineering |

| What are Linear Guide Bearings? | Basic Concept, Working Mechanism |

| History and Evolution of Linear Guide Bearings | From Early Sliding Guides to Modern Systems |

| Key Components of Linear Guide Bearings | Rails, Blocks, Rolling Elements, Housing |

| How Do Linear Guide Bearings Work? | Motion Principle, Load Transfer |

| Different Types of Linear Guide Bearings | Ball Type, Roller Type, Needle Type, Plain Type |

| Ball Linear Guide Bearings | Structure, Benefits, Limitations |

| Roller Linear Guide Bearings | Heavy Load Applications, Higher Rigidity |

| Needle Linear Guide Bearings | Compact Design, Applications |

| Plain Linear Guide Bearings | Simplicity, Maintenance-Free Use |

| Advantages of Linear Guide Bearings | Accuracy, Durability, Energy Efficiency |

| Common Applications of Linear Guide Bearings | Robotics, CNC Machines, Medical Devices |

| Linear Guide Bearings in Robotics | High-Speed Precision, Automation Benefits |

| Linear Guide Bearings in CNC Machines | Metal Cutting, Engraving, Milling |

| Use in Medical Equipment | MRI, CT Scanners, Surgical Robots |

| Choosing the Right Linear Guide Bearing | Load Capacity, Precision Needs, Environment |

| Factors Affecting Performance | Lubrication, Alignment, Material Choice |

| Installation of Linear Guide Bearings | Tools Needed, Step-by-Step Guide |

| Maintenance of Linear Guide Bearings | Cleaning, Lubrication, Inspection |

| Common Problems and Troubleshooting | Misalignment, Noise, Excessive Wear |

| Future Trends in Linear Guide Bearings | Smart Bearings, IoT Integration |

| Top Manufacturers of Linear Guide Bearings | THK, NSK, HIWIN, SKF |

| Cost Analysis of Linear Guide Bearings | Price Ranges, Value for Money |

| Comparison: Linear Guide Bearings vs. Plain Bushings | Efficiency, Durability, Use Cases |

| Linear Guide Bearings | A Recap of Importance and Future Growth |

| FAQs | Six most asked questions |

| Conclusion | Final Thoughts and Key Insights |

Introduction to Linear Guide Bearings

Linear guide bearings are essential components in modern machinery, known for their ability to provide smooth, precise, and friction-free motion. Whether in robotics, CNC machines, or medical devices, these bearings are the unsung heroes of precision engineering. Without them, automation as we know it would struggle with inaccuracies, excessive wear, and wasted energy.

What are Linear Guide Bearings?

At their core, linear guide bearings are motion systems that allow an object to move in a straight line with minimal friction. Unlike rotary bearings, which handle circular movement, linear guide bearings focus on straight-line travel. They typically consist of a rail and a carriage block equipped with rolling elements like balls or rollers. The primary purpose is to ensure accurate, repeatable motion while handling loads efficiently.

History and Evolution of Linear Guide Bearings

The idea of guiding motion in a straight path dates back centuries. Ancient civilizations used wooden slides and lubricated surfaces for basic machines. With the industrial revolution, metal-on-metal sliding guides became common. However, these suffered from friction and wear. By the 20th century, the introduction of ball bearings revolutionized linear motion systems. Today, with advancements in metallurgy, lubrication, and design, linear guide bearings are highly durable, compact, and capable of supporting heavy loads at high speeds.

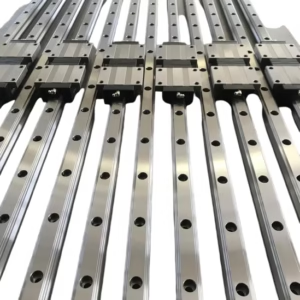

Key Components of Linear Guide Bearings

Linear guide bearings may seem simple, but their design involves several critical components:

Rails – The stationary part that guides motion.

Blocks (Carriages) – The moving component carrying the load.

Rolling Elements – Balls, rollers, or needles that reduce friction.

Housing – Provides structural support.

These components work together to ensure precision and efficiency.

How Do Linear Guide Bearings Work?

The working principle relies on rolling elements moving between the rail and block. When an external force pushes the block, the rolling elements transfer the load smoothly across the rail. This rolling contact drastically reduces friction compared to sliding contact, ensuring longer service life, reduced maintenance, and energy efficiency.

Different Types of Linear Guide Bearings

Linear guide bearings are categorized based on their rolling elements and application suitability:

Ball Linear Guide Bearings

Roller Linear Guide Bearings

Needle Linear Guide Bearings

Plain Linear Guide Bearings

Each type serves specific industrial needs.

Ball Linear Guide Bearings

Ball-type bearings use steel balls between the rail and carriage. They are popular due to their smooth motion, high accuracy, and ability to handle moderate loads. These are widely used in CNC machines and robotics. However, they are not ideal for extremely heavy loads.

Roller Linear Guide Bearings

Roller bearings use cylindrical rollers instead of balls. They provide higher rigidity and can handle heavier loads. Their design reduces deformation under pressure, making them suitable for heavy-duty industrial machinery and injection molding equipment.

Needle Linear Guide Bearings

Needle bearings are compact designs that use long, thin rollers. They save space while providing higher load capacity compared to ball bearings of the same size. Their applications include compact automation equipment and small precision tools.

Plain Linear Guide Bearings

Also known as sliding bearings, these do not have rolling elements. Instead, they rely on low-friction materials like PTFE or bronze. They are maintenance-free and excellent for applications requiring quiet, smooth motion at lower speeds.

Advantages of Linear Guide Bearings

The widespread adoption of linear guide bearings is due to their multiple advantages:

High precision and repeatability

Low friction and energy efficiency

Ability to handle heavy loads

Long service life with proper maintenance

Smooth and silent operation

Common Applications of Linear Guide Bearings

Linear guide bearings find applications in various industries:

Robotics – For high-speed, accurate automation.

CNC Machines – For precise cutting and shaping.

Medical Devices – For smooth operation in imaging and surgical tools.

Automotive Industry – For assembly lines and testing equipment.

Linear Guide Bearings in Robotics

Robotics demands accuracy and speed. Linear guide bearings allow robotic arms to move smoothly with minimal vibration, ensuring flawless automation in assembly lines, packaging, and even surgical robots.

Linear Guide Bearings in CNC Machines

CNC machines rely heavily on linear guide bearings for accurate cutting, milling, and engraving. These bearings ensure that tool paths remain consistent, resulting in high-quality finished products with minimal tolerance errors.

Use in Medical Equipment

Medical imaging machines like MRI and CT scanners use linear guide bearings for precise positioning. Surgical robots also rely on these bearings to achieve error-free, delicate movements. In such sensitive fields, accuracy is paramount.

Choosing the Right Linear Guide Bearing

When selecting linear guide bearings, several factors come into play:

Load capacity – Can the bearing handle the required weight?

Precision level – Does the application need micrometer-level accuracy?

Environment – Is it exposed to dust, moisture, or extreme temperatures?

Speed requirements – Higher speeds demand smoother rolling elements.

Factors Affecting Performance

Even the best bearings can fail if not maintained correctly. Key performance factors include:

Proper lubrication

Correct alignment during installation

High-quality materials

Regular inspection for wear

Installation of Linear Guide Bearings

Installing linear guide bearings requires precision. The rail must be mounted securely, and the block should align perfectly with it. Using torque-controlled tools helps avoid misalignment. Manufacturers usually provide detailed guidelines for correct installation.

Maintenance of Linear Guide Bearings

To ensure long life, bearings must be cleaned, inspected, and lubricated regularly. Dust and debris should be removed, and worn-out parts replaced promptly. Neglecting maintenance can lead to noise, reduced efficiency, and premature failure.

Common Problems and Troubleshooting

Noise during motion – Usually caused by lack of lubrication.

Vibration or uneven motion – Indicates misalignment.

Excessive wear – Often due to overloading.

Timely troubleshooting prevents costly downtime.

Future Trends in Linear Guide Bearings

With Industry 4.0, bearings are evolving into “smart bearings” with embedded sensors that monitor load, wear, and lubrication levels. IoT-enabled linear guide bearings will soon predict failures before they happen, reducing downtime in critical industries.

Top Manufacturers of Linear Guide Bearings

Some leading companies include:

THK (Japan)

NSK (Japan)

HIWIN (Taiwan)

SKF (Sweden)

These brands are known for innovation and reliability.

Cost Analysis of Linear Guide Bearings

The cost varies depending on size, material, and precision level. Small bearings may cost as little as $30, while high-precision industrial models can reach thousands of dollars. Investing in high-quality bearings often results in lower long-term maintenance costs.

Comparison: Linear Guide Bearings vs. Plain Bushings

| Feature | Linear Guide Bearings | Plain Bushings |

|---|---|---|

| Friction | Very low | Higher |

| Precision | High | Moderate |

| Load capacity | High (rollers) | Limited |

| Maintenance | Requires lubrication | Often maintenance-free |

| Cost | Higher upfront | Lower |

Linear Guide Bearings

Linear guide bearings have transformed modern engineering by offering unmatched precision and efficiency. They play a crucial role in robotics, CNC machining, and medical technology. With future advancements, they will only become smarter, more durable, and more indispensable.

FAQs

What is the purpose of linear guide bearings?

They ensure smooth, accurate, and low-friction linear motion in machines.

How long do linear guide bearings last?

With proper maintenance, they can last several years, even in demanding applications.

Can linear guide bearings handle heavy loads?

Yes, roller-type linear guide bearings are specifically designed for heavy-duty use.

Do linear guide bearings require lubrication?

Yes, lubrication is essential to reduce friction and wear.

Where are linear guide bearings commonly used?

In robotics, CNC machines, medical equipment, and automation industries.

What is the difference between ball and roller linear guide bearings?

Ball types are smoother and faster, while roller types are stronger and handle heavier loads.

Conclusion

Linear guide bearings are at the heart of precision engineering. Their ability to deliver smooth, accurate, and reliable motion makes them indispensable in modern industries. From robotics to medicine, they ensure machines work flawlessly. As technology advances, we can expect smarter, more efficient bearings that will further revolutionize automation.

Suggested Inbound Links:

Internal guide on CNC machining technologies

Blog on robotics in manufacturing

Article about industrial lubrication best practices