Outline for “Linear Guide”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Guide Systems | Definition, Importance in Industry |

| What is a Linear Guide? | Concept, Basic Function |

| History of Linear Guide Technology | Evolution from Sliding Guides to Precision Rails |

| Key Components of a Linear Guide | Rail, Block, Rolling Elements, Seals |

| How Does a Linear Guide Work? | Motion Mechanism, Load Distribution |

| Different Types of Linear Guides | Ball Type, Roller Type, Needle Type, Plain Type |

| Ball Linear Guide | Smooth Motion, Common Uses |

| Roller Linear Guide | Heavy Load Applications, Higher Rigidity |

| Needle Linear Guide | Compact Design, Benefits |

| Plain Linear Guide | Simplicity, Low-Maintenance Applications |

| Advantages of Linear Guide Systems | Precision, Efficiency, Durability |

| Applications of Linear Guides in Industry | Robotics, CNC Machines, Medical Equipment, Automotive |

| Linear Guide in Robotics | Automation, High-Speed Movements |

| Linear Guide in CNC Machines | Milling, Cutting, Engraving |

| Linear Guide in Medical Equipment | Imaging Machines, Surgical Robots |

| How to Choose the Right Linear Guide | Load, Precision, Environment |

| Factors That Affect Performance | Lubrication, Alignment, Material Choice |

| Installation Process of Linear Guides | Step-by-Step Guide, Tools Needed |

| Maintenance of Linear Guide Systems | Cleaning, Lubrication, Inspection |

| Common Problems in Linear Guides and Fixes | Noise, Misalignment, Wear Issues |

| Future Trends in Linear Guide Technology | Smart Guides, IoT Integration |

| Top Manufacturers of Linear Guides | THK, NSK, HIWIN, SKF |

| Cost Analysis of Linear Guides | Price Ranges, Investment Value |

| Linear Guide vs. Linear Bushings | Efficiency, Accuracy, Longevity |

| Linear Guide | Recap of Benefits and Growth |

| FAQs | Six Commonly Asked Questions |

| Conclusion | Final Thoughts |

Introduction to Linear Guide Systems

Linear guide systems are critical in modern machinery, enabling smooth, accurate, and friction-free linear motion. From robotics to CNC machining, they provide the stability and reliability industries demand. Without linear guides, high-precision work like semiconductor manufacturing, surgical robotics, and aerospace engineering would be nearly impossible.

What is a Linear Guide?

A linear guide is a mechanical system designed to guide motion in a straight line with minimal friction. Unlike rotary bearings that manage circular motion, linear guides ensure straight-line movement. They typically consist of a rail and a block (or carriage) with rolling elements that allow load-bearing movement with excellent accuracy.

History of Linear Guide Technology

Originally, linear motion systems relied on sliding surfaces—wood, bronze, or lubricated grooves. These early systems suffered from wear and inefficiency. With industrial advancements in metallurgy and precision machining, ball and roller guides emerged, revolutionizing linear motion. Today’s linear guides incorporate advanced coatings, heat treatments, and smart sensors for predictive maintenance.

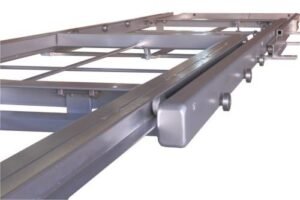

Key Components of a Linear Guide

The main components include:

Rail – The fixed path for movement.

Block (Carriage) – The moving part carrying loads.

Rolling Elements – Balls, rollers, or needles reducing friction.

Seals and Housing – Protection from dirt and debris.

Together, these ensure durability and precision.

How Does a Linear Guide Work?

A linear guide works by rolling contact between the block and the rail. The rolling elements reduce friction drastically compared to sliding contact. As the block moves, the rolling elements recirculate, enabling continuous, smooth motion with minimal resistance.

Different Types of Linear Guides

Linear guides vary depending on the rolling elements and design:

Ball Linear Guides – Best for high precision.

Roller Linear Guides – Designed for heavy-duty applications.

Needle Linear Guides – Compact and efficient.

Plain Linear Guides – Low-maintenance, sliding types.

Ball Linear Guide

Ball-type linear guides use steel balls between the rail and block. They are known for smooth motion, low friction, and accuracy. Common in CNC machines and robotics, they are ideal for applications requiring repeatability but not extreme load handling.

Roller Linear Guide

Roller guides use cylindrical rollers that provide greater rigidity and support heavy loads. They reduce deformation under stress and are often used in presses, injection molding machines, and heavy industrial robotics.

Needle Linear Guide

Needle guides use long, thin rollers. They are compact and can handle high loads for their size. These are especially useful in small, precision machinery where space is limited.

Plain Linear Guide

Plain linear guides, or sliding guides, use low-friction materials instead of rolling elements. They are quiet, require little maintenance, and are suited for slower applications where noise reduction is important.

Advantages of Linear Guide Systems

High accuracy and repeatability

Energy efficiency due to reduced friction

High load capacity

Long service life with proper care

Smooth, vibration-free motion

Applications of Linear Guides in Industry

Linear guides are widely used in:

Robotics – For precise automation.

CNC Machines – For accurate tool positioning.

Medical Devices – For imaging and surgical robotics.

Automotive Industry – For assembly lines and testing.

Linear Guide in Robotics

Robotic systems depend on linear guides for fast, precise movements. In automation, rail stability ensures accuracy and prevents vibration errors during high-speed operations.

Linear Guide in CNC Machines

CNC milling, cutting, and engraving rely on linear guides to maintain tool accuracy. They ensure smoother tool paths, higher efficiency, and better surface finishes on final products.

Linear Guide in Medical Equipment

In medical imaging equipment like MRI scanners and robotic surgical tools, linear guides provide precision and reliability. Patient safety depends on accurate, repeatable motions.

How to Choose the Right Linear Guide

Consider:

Load capacity – Does it support the required weight?

Speed – High-speed applications require smoother rolling.

Environment – Dust, moisture, or heat can affect performance.

Accuracy – Choose based on tolerance needs.

Factors That Affect Performance

Lubrication quality

Alignment accuracy during installation

Rail and block material

External environmental factors

Installation Process of Linear Guides

Steps:

Prepare a flat, clean surface.

Position and align the rail.

Secure bolts with torque control.

Install block carefully without forcing.

Test motion for smoothness.

Maintenance of Linear Guide Systems

Maintenance includes:

Regular cleaning to remove debris

Lubrication with grease or oil

Inspection for wear and noise

Replacement of damaged seals

Common Problems in Linear Guides and Fixes

Noise – Often due to lack of lubrication.

Misalignment – Leads to vibration and uneven wear.

Premature wear – Caused by overload or contaminants.

Future Trends in Linear Guide Technology

The next generation of linear guides will feature:

Smart sensors for condition monitoring

IoT-based predictive maintenance

Advanced coatings for wear resistance

Lightweight but stronger alloys

Top Manufacturers of Linear Guides

THK (Japan)

NSK (Japan)

HIWIN (Taiwan)

SKF (Sweden)

These brands are globally recognized for innovation and reliability.

Cost Analysis of Linear Guides

Linear guide costs range from $50 for basic units to thousands of dollars for high-precision industrial versions. Investing in quality often reduces downtime and maintenance costs in the long run.

Linear Guide vs. Linear Bushings

| Feature | Linear Guide | Linear Bushing |

|---|---|---|

| Friction | Very low | Moderate |

| Precision | High | Medium |

| Load Handling | Excellent | Limited |

| Maintenance | Needs lubrication | Less demanding |

| Cost | Higher | Lower |

Linear Guide

The linear guide is not merely a component; it’s the backbone of modern precision engineering. Its role in ensuring accuracy, stability, and efficiency makes it indispensable across industries.

FAQs

What is the main purpose of a linear guide?

To provide smooth, precise, and friction-free linear motion.

Are linear guides expensive?

They range in cost, but their durability makes them a valuable long-term investment.

Do linear guides require lubrication?

Yes, lubrication is essential for performance and longevity.

Which industries use linear guides most?

Robotics, CNC machining, medical equipment, and automotive industries.

What is the difference between ball and roller linear guides?

Ball guides offer smooth, fast motion, while roller guides provide higher load capacity and rigidity.

Can linear guides be used in cleanroom environments?

Yes, with special seals and lubrication options.

Conclusion

Linear guides are essential for industries demanding precision and reliability. Their ability to deliver smooth, accurate, and repeatable motion makes them irreplaceable in robotics, CNC machining, and medical equipment. With the integration of smart technology, the future of linear guides looks promising—offering not just motion, but intelligent, self-monitoring performance.

Suggested Inbound Links:

Article on robotics in manufacturing

Blog about CNC machining technologies

Guide on industrial lubrication best practices