Outline for Long-Form Article on Ball Linear Bearing

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Ball Linear Bearing | Meaning and significance, Evolution of ball bearings, Importance in engineering |

| Ball Linear Bearing | What it is, Core features, How it works |

| Design and Structure of Ball Linear Bearing | Housing, Rolling balls, Rail/shaft system |

| Types of Ball Linear Bearing | Open type, Closed type, Flanged type, Adjustable clearance type |

| Working Principle of Ball Linear Bearing | Rolling motion, Friction reduction, Load distribution |

| Advantages of Ball Linear Bearing | High precision, Low friction, Long service life, Cost-effectiveness |

| Applications of Ball Linear Bearing | CNC machines, Robotics, Medical equipment, Aerospace, Industrial automation |

| Materials Used in Ball Linear Bearing | Stainless steel, Ceramic balls, Polymer cages |

| Key Features of Ball Linear Bearing | Smooth operation, Load capacity, Quiet performance |

| Installation Guidelines for Ball Linear Bearing | Alignment tips, Lubrication practices, Handling precautions |

| Maintenance of Ball Linear Bearing | Cleaning, Lubrication intervals, Inspection routines |

| Ball Linear Bearing vs Roller Linear Bearing | Design difference, Load capacity, Cost considerations |

| Common Issues with Ball Linear Bearing | Misalignment, Noise, Contamination problems |

| Troubleshooting Ball Linear Bearing Failures | Identifying root causes, Preventive measures |

| Innovations in Ball Linear Bearing Technology | Self-lubrication, Smart monitoring, Advanced coatings |

| Ball Linear Bearing in Robotics | Precision control, Smooth motion, Energy efficiency |

| Ball Linear Bearing in CNC Machines | Accurate tool movement, Reduced vibration, Consistent quality |

| Energy Efficiency of Ball Linear Bearing | Lower power usage, Reduced wear |

| Cost-Benefit Analysis of Ball Linear Bearing | Initial investment vs long-term savings |

| Future Trends in Ball Linear Bearing | AI-based monitoring, Miniaturization, Sustainable materials |

| Case Studies Using Ball Linear Bearing | Automotive industry, Semiconductor manufacturing, Aerospace systems |

| Safety Considerations in Ball Linear Bearing Usage | Load safety, Operator protection |

| Global Market of Ball Linear Bearing | Current growth, Leading manufacturers, Market trends |

| FAQs about Ball Linear Bearing | Six FAQs with detailed answers |

| Conclusion on Ball Linear Bearing | Final thoughts, Key takeaways |

| Suggestions for Internal & External Links | Inbound and outbound link recommendations |

Introduction to Ball Linear Bearing

Ball linear bearings are one of the most vital components in modern motion systems. If you’ve ever marveled at the precision of a CNC machine, the smooth glide of a 3D printer head, or the quiet efficiency of robotic arms, then you’ve indirectly witnessed the magic of ball linear bearings.

These specialized bearings are designed to provide smooth, straight-line motion with minimal friction. Unlike traditional bearings that allow circular or rotary motion, ball linear bearings focus solely on guiding loads along a linear path. This makes them indispensable in industries where precision, repeatability, and efficiency are non-negotiable.

Historically, engineers used plain sliding surfaces made of wood, bronze, or lubricated metals to achieve linear movement. While functional, these older methods were inefficient and wore down quickly. With the development of hardened steel, ceramics, and advanced polymer cages, the ball linear bearing was born—offering unmatched accuracy and longevity.

In an era dominated by automation, robotics, and advanced manufacturing, ball linear bearings continue to play a pivotal role in ensuring reliability, precision, and cost efficiency.

Ball Linear Bearing

A ball linear bearing is a mechanical device that utilizes recirculating balls to enable straight-line motion with reduced friction. These bearings are mounted on shafts or rails, and the rolling balls inside continuously circulate to support loads and facilitate smooth travel.

They are widely used in equipment that requires high accuracy and repeatable motion, such as:

CNC machining centers

Robotic arms

Semiconductor production systems

Medical diagnostic equipment

Automated packaging machinery

What sets ball linear bearings apart is their ability to carry significant loads while maintaining exceptional smoothness and precision.

Design and Structure of Ball Linear Bearing

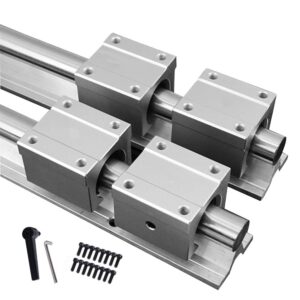

The design of ball linear bearings may vary depending on the manufacturer and application, but the key components include:

Housing: The outer body that encases the bearing elements.

Recirculating Balls: Hardened steel or ceramic balls that reduce friction by rolling rather than sliding.

Rail or Shaft: A precisely machined, hardened guide that ensures accurate linear travel.

Cage or Retainer: Keeps the balls evenly spaced to prevent contact and ensure smooth circulation.

This simple yet effective structure allows for efficient motion, reduced energy use, and minimal wear.

Types of Ball Linear Bearing

Different applications demand different types of ball linear bearings:

Open Type: Designed for applications where the shaft is supported by a base, providing access from one side.

Closed Type: Fully enclosed, suitable for free-standing shafts without external support.

Flanged Type: Comes with a flange for easy mounting to machine frames.

Adjustable Clearance Type: Allows fine-tuning of internal clearance to meet precision requirements.

Each type offers unique advantages, making selection dependent on load, speed, and environmental conditions.

Working Principle of Ball Linear Bearing

The principle is elegantly simple yet powerful. Ball linear bearings reduce sliding friction by converting it into rolling friction.

Rolling Motion: Recirculating balls roll between the shaft and housing, carrying loads efficiently.

Friction Reduction: Rolling friction is significantly lower than sliding friction, which reduces energy losses.

Load Distribution: The balls distribute loads evenly, preventing stress points and increasing lifespan.

Imagine dragging a heavy object across a floor versus rolling it on marbles—the latter requires far less effort. This analogy captures the essence of how ball linear bearings operate.

Advantages of Ball Linear Bearing

The benefits of using ball linear bearings are wide-ranging:

High Precision: Ensures micron-level accuracy, ideal for robotics and semiconductor industries.

Low Friction: Reduces power consumption and heat buildup.

Long Service Life: Properly maintained bearings last years, even in demanding applications.

Cost-Effectiveness: Although the initial investment may be higher, long-term savings outweigh the cost.

Compact Design: Fits into machinery with limited space.

Quiet Operation: Reduces noise in sensitive environments like labs.

Low Maintenance: Self-lubricating options minimize servicing needs.

These features explain why industries across the globe rely on ball linear bearings for critical operations.

Applications of Ball Linear Bearing

Ball linear bearings are found in countless industries:

CNC Machines: Enable smooth, precise cutting and shaping.

Robotics: Power robotic arms with repeatable, accurate movements.

Medical Equipment: Ensure precision in imaging systems, surgical robots, and laboratory instruments.

Aerospace: Provide stability in simulators and testing rigs.

Industrial Automation: Improve efficiency in conveyors, packaging, and assembly systems.

Their adaptability makes them a universal solution in fields requiring linear motion.

Materials Used in Ball Linear Bearing

The choice of material impacts performance and durability:

Stainless Steel: Strong, corrosion-resistant, ideal for heavy-duty or harsh environments.

Ceramic Balls: Lightweight, wear-resistant, perfect for high-speed applications.

Polymer Cages: Keep balls in place while reducing noise and friction.

Manufacturers often combine these materials to create the perfect balance of strength, smoothness, and longevity.

Key Features of Ball Linear Bearing

Some defining features include:

Smooth Operation: Rolling balls ensure frictionless motion.

High Load Capacity: Capable of handling both dynamic and static loads.

Quiet Performance: Essential for cleanrooms and laboratories.

Versatility: Suitable for small instruments and large industrial machines alike.

These features make them one of the most versatile motion solutions available.

Installation Guidelines for Ball Linear Bearing

Proper installation is crucial to achieving optimal performance:

Alignment: Misalignment leads to uneven wear and noise.

Surface Preparation: Mounting surfaces must be clean and flat.

Lubrication: Apply recommended grease or oil to reduce wear.

Handling: Avoid contamination by wearing gloves and keeping components dust-free.

Correct installation significantly extends service life.

Maintenance of Ball Linear Bearing

Even the most durable bearings require maintenance:

Cleaning: Remove dust and contaminants regularly.

Lubrication Intervals: Follow manufacturer guidelines for re-lubrication.

Inspection: Listen for unusual noise or check for vibration.

Replacement: Replace worn-out bearings before failure causes machine downtime.

Preventive maintenance reduces unexpected breakdowns and costs.

Ball Linear Bearing vs Roller Linear Bearing

Though similar, these two systems differ:

Ball Bearings: Offer smoother motion, lower friction, and higher precision.

Roller Bearings: Handle heavier loads but may not match the precision of ball bearings.

Cost: Roller bearings are more expensive in heavy-duty applications, while ball bearings are more cost-effective in general machinery.

The choice depends on whether the priority is precision or load-bearing capacity.

Common Issues with Ball Linear Bearing

Even high-quality bearings can face issues:

Misalignment: Causes uneven wear and reduces accuracy.

Noise: Often due to contamination or poor lubrication.

Vibration: Can damage sensitive equipment like optics.

Overheating: A result of excess speed or improper lubrication.

Identifying these problems early prevents costly failures.

Troubleshooting Ball Linear Bearing Failures

Steps to troubleshoot issues include:

Check Alignment: Realign bearings if wear patterns indicate problems.

Verify Lubrication: Apply correct grease or oil.

Inspect Environment: Remove dust or contaminants.

Monitor Load: Ensure the system isn’t overloaded.

Addressing root causes quickly keeps systems running smoothly.

Innovations in Ball Linear Bearing Technology

Recent advancements are improving performance further:

Self-Lubrication: Bearings with built-in lubricants reduce maintenance needs.

Smart Monitoring: Sensors detect wear and send alerts.

Advanced Coatings: Nanotechnology-based coatings extend service life.

Lightweight Materials: Composites reduce weight without compromising strength.

These innovations align with trends in automation and sustainability.

Ball Linear Bearing in Robotics

Robotics relies heavily on precision motion:

Smooth Motion: Ensures robotic arms operate without jerks.

Energy Efficiency: Reduces battery consumption in mobile robots.

High Repeatability: Essential for tasks like electronic assembly.

Without ball linear bearings, the accuracy and speed of modern robots would be compromised.

Ball Linear Bearing in CNC Machines

CNC machining demands accuracy and consistency:

Accurate Tool Movement: Bearings keep cutting tools on precise paths.

Reduced Vibration: Protects tools and improves surface finishes.

Consistency: Ensures every manufactured part meets strict tolerances.

This makes ball linear bearings essential for industries that depend on CNC machining.

Energy Efficiency of Ball Linear Bearing

Efficiency is not just about performance—it’s also about sustainability:

Lower Power Usage: Less friction reduces energy needs.

Reduced Wear: Extends machine lifespan, lowering replacement costs.

Eco-Friendly Operation: Recyclable materials and longer service life support sustainability.

This makes them a win-win for cost savings and environmental responsibility.

Cost-Benefit Analysis of Ball Linear Bearing

While upfront costs may seem high, the benefits outweigh them:

Reduced Downtime: Minimizes lost productivity.

Lower Maintenance Costs: Self-lubricating designs save labor.

Longevity: Spreads investment across years of use.

In the long term, ball linear bearings are more economical than cheaper, short-lived alternatives.

Future Trends in Ball Linear Bearing

Looking ahead, exciting developments are on the horizon:

AI-Based Monitoring: Predictive maintenance powered by AI.

Miniaturization: Tiny bearings for micro-robots and electronics.

Sustainable Materials: Biodegradable or recyclable components.

These trends align with Industry 4.0 and green manufacturing goals.

Case Studies Using Ball Linear Bearing

Automotive Industry: Precision assembly lines use ball bearings for automation.

Semiconductor Manufacturing: Critical in wafer handling systems.

Aerospace Systems: Essential for simulators and testing rigs requiring smooth, precise motion.

These real-world cases highlight their versatility and necessity.

Safety Considerations in Ball Linear Bearing Usage

Safety should never be overlooked:

Load Safety: Avoid exceeding rated load capacity.

Operator Protection: Use guards and shields to prevent accidents.

Regular Inspections: Detect potential failures before they become hazards.

These practices ensure both human and machine safety.

Global Market of Ball Linear Bearing

The market is expanding rapidly:

Growth Drivers: Automation, robotics, and industrial modernization.

Leading Manufacturers: NSK, THK, HIWIN, SKF, and Bosch Rexroth.

Market Trends: Expected CAGR of 6–7% in the next decade.

This reflects the global demand for precision and efficiency in engineering.

FAQs about Ball Linear Bearing

What is a ball linear bearing used for?

It is used to provide smooth, precise linear motion in machines and automated systems.

What industries rely on ball linear bearings?

Industries include robotics, CNC machining, aerospace, medical equipment, and packaging.

How long do ball linear bearings last?

With proper lubrication and care, they can last years, even in heavy-duty applications.

Do they require lubrication?

Yes, except in self-lubricating models, which reduce maintenance needs.

Are ball linear bearings expensive?

They may cost more initially, but long-term savings make them cost-effective.

How do they differ from roller linear bearings?

Ball bearings offer smoother, more precise motion, while roller bearings carry heavier loads.

Conclusion on Ball Linear Bearing

Ball linear bearings may be compact, but their impact is enormous. By ensuring smooth, accurate, and reliable linear motion, they drive industries ranging from robotics to aerospace. Their advantages—precision, durability, and energy efficiency—make them indispensable in the modern world of automation.

With innovations like self-lubricating systems and AI-driven monitoring, the future of ball linear bearings looks even brighter. Businesses that adopt them can expect not only cost savings but also improved sustainability and competitiveness.

Suggestions for Internal & External Links

Inbound Links:

Guide to CNC Machine Precision

Advantages of Linear Bearings in Robotics

Industrial Automation with Bearings

Outbound Links: