Outline for Linear Rail Guide

| Main Topic | Sub-Topics / Sub-Headings |

|---|---|

| Introduction | Why Linear Rail Guide Matters Today |

| Linear Rail Guide | Definition and Primary Purpose |

| History of Linear Rail Guide | From Early Rails to High-Tech Systems |

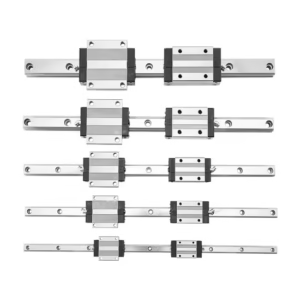

| Key Components of Linear Rail Guide | Rails, Blocks, Bearings, and End Caps |

| Types of Linear Rail Guide | Ball Type, Roller Type, Miniature, Heavy-Duty |

| Linear Rail Guide vs. Linear Bearing Guide | Key Differences and Uses |

| Advantages of Linear Rail Guide | Precision, Load Capacity, and Durability |

| Applications in CNC Machining | Accurate Tool and Workpiece Movement |

| Linear Rail Guide in Robotics | Repeatability and Reliability |

| Use in Industrial Automation | Enhancing Smart Factory Operations |

| Medical Equipment Applications | Imaging Systems and Surgical Robotics |

| Aerospace and Defense Applications | Precision in Extreme Conditions |

| Choosing the Right Linear Rail Guide | Factors to Consider |

| Installation Guide | Step-by-Step Setup Process |

| Maintenance Tips | Lubrication, Cleaning, and Inspections |

| Common Problems and Fixes | Noise, Misalignment, and Wear |

| Enhancing Performance | Using Smart Sensors and Dust Covers |

| Cost of Linear Rail Guide | Budget vs. Premium Options |

| Top Manufacturers | THK, Hiwin, NSK, Bosch Rexroth |

| Brand Comparisons | Pros and Cons of Popular Options |

| Linear Rail Guide in 3D Printing | Stable and Accurate Printing Motion |

| Future of Linear Rail Guide | IoT, AI, and Smart Materials |

| Eco-Friendly Linear Rail Guides | Sustainability and Energy Efficiency |

| DIY Uses of Linear Rail Guide | CNC, 3D Printers, Camera Sliders |

| Troubleshooting Tips | Solving Common Issues Quickly |

| Buying Checklist | What to Confirm Before Purchase |

| Conclusion | Why Linear Rail Guide is Essential in 2025 |

| FAQs | Answering Common Questions |

Introduction

In today’s high-tech world, precision is the lifeline of modern engineering. Whether in CNC machining, robotics, or aerospace, achieving accurate and reliable linear motion is critical. At the heart of this capability lies the linear rail guide.

This system ensures smooth, friction-free movement along a straight path, making it essential for industries that demand accuracy, durability, and efficiency. From guiding robotic arms to stabilizing medical imaging equipment, linear rail guides are everywhere—even if we rarely notice them.

This comprehensive article explores everything you need to know about linear rail guides—their history, components, benefits, applications, and future trends.

Linear Rail Guide

A linear rail guide is a motion system that uses rails and sliding blocks (carriages) to provide smooth, precise linear motion. The block travels along the rail using ball bearings or rollers, reducing friction while supporting heavy loads.

These systems excel in applications where accuracy, rigidity, and long service life are non-negotiable.

History of Linear Rail Guide

The story of linear rails is a fascinating one:

Early Era: Wooden and metal grooves for carts and machines.

Industrial Age: Sliding rails with high friction.

20th Century: Invention of rolling-element bearings transformed performance.

Modern Day: High-tech materials, corrosion-resistant coatings, and IoT monitoring bring unprecedented efficiency.

Key Components of Linear Rail Guide

The system is composed of:

Rail: The guiding track.

Block (Carriage): Moves smoothly along the rail.

Bearings: Balls or rollers to reduce friction.

End Caps & Seals: Prevent dirt contamination.

Lubrication Ports: Ensure continuous smooth motion.

Types of Linear Rail Guide

Different rail types meet different needs:

Ball Type: Smooth and fast.

Roller Type: Handles heavy loads.

Miniature Rails: Compact for electronics.

Heavy-Duty Rails: Industrial and aerospace-grade.

Linear Rail Guide vs. Linear Bearing Guide

| Feature | Linear Rail Guide | Linear Bearing Guide |

|---|---|---|

| Design | Rail and block system | Shaft and bearing system |

| Load Capacity | Very high | Medium to high |

| Precision | Exceptional | High |

| Applications | CNC, robotics, aerospace | DIY, automation, smaller systems |

Advantages of Linear Rail Guide

Superior Accuracy

High Load Capacity

Durability and Long Life

Reduced Friction

Smooth, Quiet Operation

Applications in CNC Machining

Linear rail guides ensure micron-level precision in CNC cutting, milling, and drilling. They provide:

Enhanced productivity.

Higher surface quality.

Extended machine life.

Linear Rail Guide in Robotics

Robotics depends on repeatable accuracy. Linear rails guide robotic arms and gantries, ensuring precise movements in assembly, packaging, and logistics automation.

Use in Industrial Automation

Smart factories rely on linear rails in:

Conveyor systems.

Pick-and-place robots.

Packaging lines.

Their reliability minimizes downtime.

Medical Equipment Applications

Linear rail guides are used in:

MRI and CT scanners.

Surgical robots.

Lab automation equipment.

They ensure delicate, accurate movement.

Aerospace and Defense Applications

In aerospace, precision is life-critical. Linear rails withstand extreme vibration, loads, and environmental stress in aircraft assembly, testing, and satellite manufacturing.

Choosing the Right Linear Rail Guide

Key factors:

Load capacity.

Precision requirements.

Speed and acceleration.

Operating environment.

Budget.

Installation Guide

Prepare clean, flat surfaces.

Align rails precisely.

Bolt evenly with correct torque.

Mount blocks carefully.

Lubricate before use.

Maintenance Tips

Regular lubrication.

Cleaning debris.

Seal checks.

Bearing replacements.

Alignment checks.

Common Problems and Fixes

Noise: Add lubrication.

Misalignment: Realign rails.

Wear: Replace blocks.

Contamination: Use protective covers.

Enhancing Performance

Improve performance with:

Smart lubrication.

IoT-enabled sensors.

Roller blocks for heavy loads.

Dust protection systems.

Cost of Linear Rail Guide

DIY use: $50–$200

Industrial use: $500–$3,000

Aerospace/medical: $10,000+

Top Manufacturers

THK

Hiwin

NSK

Bosch Rexroth

Brand Comparisons

THK: High-end, aerospace-grade.

Hiwin: Affordable and reliable.

NSK: Excellent lifespan.

Bosch Rexroth: Great for industrial automation.

Linear Rail Guide in 3D Printing

Linear rails improve print head stability and ensure smooth, accurate printing—critical for both hobbyists and industrial 3D printers.

Future of Linear Rail Guide

The next decade will see:

IoT integration.

AI diagnostics.

Eco-friendly materials.

Self-lubricating designs.

Eco-Friendly Linear Rail Guides

Sustainability is achieved through:

Recyclable materials.

Low-friction coatings.

Energy-efficient designs.

DIY Uses of Linear Rail Guide

Popular projects include:

3D printers.

CNC machines.

Camera sliders.

Home automation rigs.

Troubleshooting Tips

Jamming: Remove debris.

Vibration: Realign and lubricate.

Reduced accuracy: Replace bearings.

Corrosion: Use stainless steel rails.

Buying Checklist

Verify load capacity.

Confirm dimensions.

Choose reputable brands.

Check warranty.

Ensure environmental compatibility.

Conclusion

The linear rail guide is far more than a mechanical component—it is the foundation of precision motion systems. From CNC machining and robotics to aerospace and medical devices, it enables smooth, reliable, and accurate performance.

As industries move toward smarter, greener solutions, linear rail guides will continue to evolve with IoT, AI, and eco-friendly innovations, ensuring they remain indispensable well into the future.

FAQs

What is a linear rail guide used for?

It ensures smooth, accurate linear motion in machines like CNCs, robots, and automation systems.

Is it the same as a linear bearing?

No, bearings use shafts, while rails use blocks and profiled rails.

Do linear rail guides need lubrication?

Yes, lubrication is essential for longevity and performance.

Which industries use linear rail guides?

Manufacturing, robotics, aerospace, and medical equipment.

How much do they cost?

From $50 for DIY models to over $10,000 for specialized systems.

How long do they last?

With maintenance, 10–20 years or more.

Suggested Inbound Links

CNC machining essentials

Robotics in automation

Guide to 3D printing motion systems