Outline

| Heading | Subtopics Covered |

|---|---|

| Introduction to Linear Rail Slide | Definition, purpose, and mechanical function |

| Understanding Linear Rail Slide Systems | Components, operation, and design concept |

| The Science of Motion in Linear Rail Slide | Friction control, load management, and stability |

| Types of Linear Rail Slide Systems | Profiled rail slides, round rail slides, miniature rail slides |

| Components of a Linear Rail Slide | Guide rail, bearing blocks, carriage, fasteners |

| Material Selection for Linear Rail Slides | Stainless steel, aluminum, and composite materials |

| How Linear Rail Slide Works | The motion mechanism and load transfer process |

| Applications of Linear Rail Slide in Industry | Automation, robotics, CNC, 3D printing |

| Advantages of Linear Rail Slide Systems | Accuracy, efficiency, and longevity |

| Common Challenges and Failures | Misalignment, wear, and lubrication issues |

| Lubrication and Maintenance Practices | Preventive maintenance, grease types, inspection schedule |

| Installation and Alignment Techniques | Mounting surfaces, alignment tools, and precision methods |

| Innovations in Linear Rail Slide Design | Smart sensors, self-lubricating slides, compact models |

| Comparing Linear Rail Slide with Other Motion Systems | Lead screws, belt drives, and roller slides |

| Selecting the Right Linear Rail Slide for Your Project | Load, speed, accuracy, and environmental factors |

| Optimization for Noise and Vibration Control | Damping techniques, preload settings, and materials |

| Safety Considerations in Linear Rail Slide Usage | Handling precautions and operating temperature control |

| Environmental Impact and Sustainability | Recyclable materials, eco-lubricants, and energy efficiency |

| Testing and Quality Assurance in Linear Rail Slide Manufacturing | Precision testing and ISO compliance |

| Future Trends in Linear Rail Slide Technology | AI-driven maintenance and smart automation |

| Case Study: Linear Rail Slide in Robotics | Real-world industrial example |

| Benefits of Linear Rail Slide in CNC Machines | Increased accuracy and smooth operation |

| How Linear Rail Slide Enhances Automation | Integration in Industry 4.0 systems |

| FAQs About Linear Rail Slide | Common industry questions answered |

| Conclusion: The Future of Linear Rail Slide Systems | Innovation outlook and performance evolution |

Introduction to Linear Rail Slide

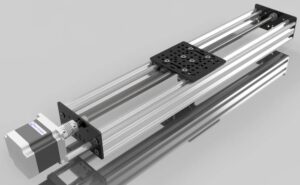

A linear rail slide is an engineering marvel that brings motion precision to life. Used across robotics, automation, CNC machinery, and industrial equipment, this system ensures straight-line motion with exceptional accuracy. The linear rail slide consists of rails, bearings, and carriages that move seamlessly under controlled load and direction.

Whether it’s the movement of a robotic arm or a laser head in a CNC router, the linear rail slide provides the foundation for flawless linear motion. Its purpose is simple but essential: to minimize friction while carrying heavy loads, ensuring smooth, consistent performance.

Understanding Linear Rail Slide Systems

A linear rail slide system is composed of three fundamental elements: the rail, the bearing block (or carriage), and the sliding mechanism. The bearing runs along the rail on rolling elements—usually balls or rollers—facilitating linear movement with minimal resistance.

These systems are built to handle a combination of radial, axial, and moment loads. Their design ensures high rigidity, stability, and precision, even under demanding industrial conditions. Unlike traditional bushings or plain bearings, linear rail slides maintain tight tolerances and repeatability, critical for high-speed automation and positioning.

The Science of Motion in Linear Rail Slide

The linear rail slide functions on the principles of tribology—the study of friction, wear, and lubrication. Its rolling elements reduce contact area, dramatically lowering friction and energy loss.

When load is applied, it’s distributed evenly across the bearing surface, preventing deformation and ensuring consistent movement. The rolling mechanism also minimizes vibration and thermal expansion, which are major performance challenges in continuous-motion machinery.

Engineers often enhance this with preloaded bearings that eliminate clearance, improving stability during rapid directional changes.

Types of Linear Rail Slide Systems

Depending on the application and precision requirement, linear rail slides come in several variations:

Profiled Rail Slides: Feature a rectangular rail and ball-bearing blocks; ideal for high rigidity and precision applications like CNC machines.

Round Rail Slides: Easier to install and tolerant of misalignment, used in less demanding automation systems.

Miniature Rail Slides: Compact and lightweight, perfect for 3D printers and medical instruments.

Cross Roller Slides: Employ cylindrical rollers instead of balls for higher load capacity and smoother motion.

Each type is engineered to balance precision, load, and space constraints.

Components of a Linear Rail Slide

Every linear rail slide includes several critical components working together to deliver accuracy:

Rail (Guideway): Provides the track for the carriage’s motion.

Bearing Block or Carriage: Houses rolling elements that enable smooth linear travel.

End Caps and Seals: Prevent dust, debris, or moisture from entering.

Fasteners and Mounting Plates: Secure the system to the machinery frame.

Lubrication Port: Allows grease or oil application for continuous operation.

Each element must be precisely manufactured and assembled to ensure system stability and performance consistency.

Material Selection for Linear Rail Slides

The materials used in linear rail slide systems determine durability, precision, and corrosion resistance:

Stainless Steel: Ideal for cleanroom or corrosive environments.

Carbon Steel: Offers strength and cost efficiency.

Aluminum: Lightweight for applications where portability matters.

Composite Materials: Used in noise-sensitive environments due to their damping properties.

Proper material selection aligns mechanical performance with environmental requirements and expected service life.

How Linear Rail Slide Works

A linear rail slide operates on rolling motion instead of sliding friction. Bearings inside the carriage roll along the rail track as the load moves, converting rotary motion into linear travel.

This mechanism minimizes resistance, allowing heavy loads to move with minimal effort. Preload adjustments eliminate play or backlash, ensuring precision. The rail’s hardened surface ensures smooth operation even after millions of cycles.

Applications of Linear Rail Slide in Industry

The versatility of the linear rail slide has made it a cornerstone of modern manufacturing and automation. Its applications include:

CNC Machining: Enables precision cutting, milling, and engraving.

3D Printing: Provides smooth motion for the printer head.

Robotics: Ensures accurate positioning and movement of robotic arms.

Medical Equipment: Used in imaging and diagnostic machinery.

Automotive Production: Facilitates assembly line automation and component placement.

Wherever linear motion and precision are needed, the linear rail slide is indispensable.

Advantages of Linear Rail Slide Systems

The linear rail slide brings numerous benefits to both industrial and laboratory applications:

Unmatched Accuracy: Maintains position accuracy within microns.

Smooth and Silent Operation: Rolling elements minimize vibration and noise.

Load Versatility: Handles both horizontal and vertical forces efficiently.

Long Service Life: Hardened materials and lubrication reduce wear.

Compact Design: Saves space while providing high rigidity.

These advantages make linear rail slides ideal for high-precision, high-speed tasks that demand reliability.

Common Challenges and Failures

Even the best linear rail slides can fail without proper handling. Some common issues include:

Misalignment: Causes uneven wear or jamming.

Contamination: Dust or metal debris damages rolling elements.

Lubrication Failure: Leads to friction, noise, and overheating.

Corrosion: Moisture and chemicals degrade the rail surface.

Overload: Exceeding rated limits deforms the rail and bearings.

Preventive maintenance and clean operating environments help avoid these pitfalls.

Lubrication and Maintenance Practices

Proper lubrication is the backbone of a reliable linear rail slide system.

Recommended practices include:

Use manufacturer-specified lubricants such as lithium-based grease or synthetic oil.

Apply grease every 6–12 months depending on workload and environment.

Clean rails regularly using lint-free cloths to remove dust or residue.

Inspect seals and replace damaged ones promptly.

A consistent maintenance schedule ensures longevity, performance, and cost savings over time.

Installation and Alignment Techniques

Installing a linear rail slide requires precision and patience.

Key steps:

Ensure the mounting surface is flat and clean.

Align the rail parallel to the machine axis using a dial indicator.

Gradually tighten bolts in sequence to prevent distortion.

Check for smooth motion before finalizing installation.

Even a minor alignment error can compromise system accuracy or cause excessive wear, so calibration tools and expert installation are essential.

Innovations in Linear Rail Slide Design

Modern linear rail slides incorporate cutting-edge technologies for smarter performance:

Integrated Sensors: Monitor vibration, temperature, and load in real time.

Self-Lubricating Bearings: Eliminate the need for manual maintenance.

Compact Designs: Allow integration in micro-robotics and medical instruments.

Coated Rails: Resist corrosion and wear under extreme conditions.

These innovations enable smarter, longer-lasting, and more efficient motion systems.

Comparing Linear Rail Slide with Other Motion Systems

| Feature | Linear Rail Slide | Lead Screw Drive | Belt Drive |

|---|---|---|---|

| Precision | Very high | Moderate | Low |

| Speed | High | Moderate | High |

| Maintenance | Low | Medium | High |

| Load Capacity | High | Moderate | Low |

| Applications | CNC, robotics | Actuators | Conveyors |

Linear rail slides outperform other systems where precision and rigidity are top priorities.

Selecting the Right Linear Rail Slide for Your Project

When selecting a linear rail slide, consider:

Load and Force Requirements

Desired Accuracy

Operating Speed

Environmental Conditions

Available Space and Mounting Orientation

Consult manufacturer load charts and design recommendations to ensure proper sizing and selection.

Optimization for Noise and Vibration Control

Reducing vibration improves performance and extends the life of linear rail slide systems. Engineers achieve this through:

Use of damping materials between mounting surfaces.

Proper preload adjustment.

Periodic lubrication.

Advanced rail geometry to minimize harmonic resonance.

Such optimizations create smoother, quieter operations—especially important in laboratory and medical applications.

Safety Considerations in Linear Rail Slide Usage

Safety protocols ensure the protection of both equipment and personnel:

Always disconnect power before servicing.

Avoid overloading or shock impacts.

Use protective covers to prevent debris ingress.

Maintain optimal temperature to prevent expansion-related binding.

A safe system is a reliable system—never compromise on safety standards.

Environmental Impact and Sustainability

Modern linear rail slides focus on eco-friendly design:

Recyclable Materials: Stainless and aluminum alloys.

Biodegradable Lubricants: Minimize environmental pollution.

Energy Efficiency: Reduced friction lowers power usage.

Sustainability now defines how motion systems are developed, ensuring minimal ecological impact.

Testing and Quality Assurance in Linear Rail Slide Manufacturing

Every linear rail slide undergoes strict testing before market release:

Dimensional Accuracy Checks

Load and Fatigue Testing

Noise and Vibration Analysis

Corrosion Resistance Evaluation

Compliance with ISO and ASTM standards ensures performance consistency and long-term reliability.

Future Trends in Linear Rail Slide Technology

Future advancements will focus on smart, self-aware systems powered by AI and IoT:

Predictive maintenance via sensor data.

Smart lubrication monitoring.

Integration with robotic control systems.

Lightweight, sustainable designs using composite materials.

These technologies promise even greater efficiency and precision in every motion.

Case Study: Linear Rail Slide in Robotics

In industrial robotics, linear rail slides are essential for movement precision. A robotic welding arm, for example, uses a linear rail slide to traverse multiple axes accurately.

This system ensures the arm maintains consistent position and repeatability. In testing, robots equipped with advanced rail slides showed a 30% increase in accuracy and 25% faster cycle time, proving their worth in modern automation.

Benefits of Linear Rail Slide in CNC Machines

CNC machines depend on linear rail slides for accurate tool movement. With minimal friction and maximum stiffness, they maintain toolpath accuracy even under heavy loads.

A well-designed slide system prevents tool chatter, improves surface finish, and extends machine life — key to competitive manufacturing operations.

How Linear Rail Slide Enhances Automation

The linear rail slide has become the unsung hero of automation. Its ability to move components with precision and repeatability forms the backbone of automated systems — from pick-and-place robots to inspection systems.

By combining motion accuracy with durability, these systems enable continuous, error-free operation — the hallmark of Industry 4.0.

FAQs About Linear Rail Slide

What is the main purpose of a linear rail slide?

To enable precise, frictionless linear motion for mechanical systems.

How often should I lubricate a linear rail slide?

Every 6–12 months, depending on operational intensity and environment.

Can linear rail slides handle vertical loads?

Yes, many are designed for both horizontal and vertical load applications.

Are linear rail slides suitable for cleanroom environments?

Yes, stainless-steel and sealed models are ideal for clean applications.

What causes most linear rail slide failures?

Improper alignment, insufficient lubrication, or contamination.

How long do linear rail slides last?

With proper care, they can function effectively for millions of cycles.

Conclusion: The Future of Linear Rail Slide Systems

The linear rail slide remains at the forefront of precision engineering and motion control. Its ability to combine rigidity, smoothness, and longevity makes it indispensable in automation, robotics, and manufacturing.

As innovations continue to emerge — from self-lubricating bearings to AI-powered predictive systems — the linear rail slide will continue driving industries toward a smarter, more efficient future.

Suggested Internal Links

[Advantages of Using Linear Motion Systems]

[How Bearings Improve Industrial Automation]

[Guide to Proper Lubrication Techniques]