Outline for “Linear Rails CNC”

| Section | Subtopics |

|---|---|

| Introduction | Importance of linear rails in CNC machining |

| What Are Linear Rails CNC Systems? | Definition and working principles |

| How Linear Rails Function in CNC Machines | Rolling elements, preload, and motion control |

| Key Components of CNC Linear Rail Systems | Rails, blocks, bearings, and lubrication ports |

| Engineering Excellence at YH Linear | Material technology and design precision |

| Benefits of Using Linear Rails in CNC Machines | Rigidity, speed, and accuracy |

| Types of CNC Linear Rails | Ball-type, roller-type, and miniature versions |

| Performance Features of YH Linear Rails | Precision levels, contact angles, and load capacity |

| Material Quality and Heat Treatment | SUJ2 steel, stainless alloys, and surface finishing |

| Installation and Alignment Guidelines | CNC setup and calibration best practices |

| Lubrication and Maintenance Tips | Ensuring long-lasting smooth performance |

| Comparison: Linear Rails vs Round Shaft Guides | Structural and functional advantages |

| YH Linear’s Innovations in CNC Motion Technology | Design enhancements and industrial use cases |

| Common Issues and Solutions in CNC Rail Systems | Vibration, misalignment, and contamination fixes |

| Applications Across CNC Industries | Milling, lathes, engraving, 3D printing, robotics |

| Customization and OEM Options by YH Linear | Tailored CNC rail systems for unique requirements |

| Quality Certifications and Testing Standards | ISO, CE, and internal QC systems |

| Sustainability in CNC Manufacturing | Eco-friendly materials and energy-efficient designs |

| Future of CNC Linear Rail Technology | Smart sensors and AI integration |

| FAQs | Technical and buyer-oriented questions |

| Conclusion | Recap and YH Linear’s call to action |

| Suggested Links | Inbound and outbound SEO recommendations |

Linear Rails CNC

In the high-precision world of CNC machining, accuracy, stability, and smooth motion define success. The linear rails CNC system forms the backbone of that precision—guiding every tool, spindle, and table movement with absolute consistency.

At YH Linear (https://yhlinear.com/), our CNC linear rails are engineered to deliver unmatched performance, ensuring your machines achieve superior accuracy, longer service life, and effortless motion control.

What Are Linear Rails CNC Systems?

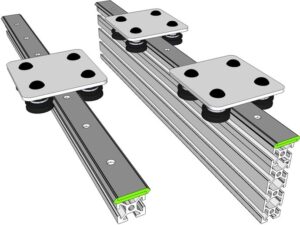

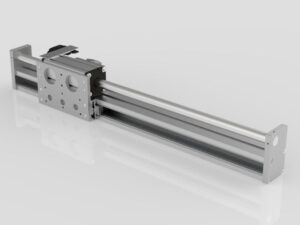

A linear rail CNC system is a precision motion component that supports and guides linear movement in CNC machines using a rail and a carriage (or block).

Unlike traditional slide mechanisms that rely on surface contact, CNC linear rails use rolling elements such as balls or rollers to minimize friction, resulting in high-speed and high-accuracy movement.

This advanced motion technology allows CNC equipment to produce micron-level cuts, engravings, and machining tolerances.

How Linear Rails Function in CNC Machines

Within the CNC machine structure, linear rails guide the motion of spindles, tables, or tools along a precise axis.

Inside the rail carriage, hardened steel balls or rollers circulate through smooth raceways. As they roll, they transfer the machine load uniformly, reducing wear and providing consistent, vibration-free motion.

This mechanism ensures that the CNC system operates with maximum rigidity, minimal friction, and reliable positioning accuracy.

Key Components of CNC Linear Rail Systems

| Component | Function |

|---|---|

| Guide Rail | Precision track for linear motion |

| Carriage Block | Moves smoothly along the rail carrying loads |

| Rolling Elements | Steel balls or rollers that enable frictionless movement |

| End Caps & Seals | Protect against dust and debris contamination |

| Lubrication Ports | Allow consistent grease or oil application |

| Mounting Holes | Secure rail alignment during CNC assembly |

Each YH Linear rail is precision-ground and heat-treated for maximum hardness and dimensional stability.

Engineering Excellence at YH Linear

YH Linear’s CNC rails are developed using high-precision CNC grinding and heat treatment technology. Key engineering highlights include:

Four-way equal load design for balance under vertical and horizontal loads

45° contact angle design for superior rigidity

High preload accuracy ensuring vibration-free motion

Noise-damping circulation paths for quiet operation

Anti-rust coatings suitable for humid and coolant-exposed environments

Every component is manufactured to micron-level tolerances, ensuring total performance reliability.

Benefits of Using Linear Rails in CNC Machines

Ultra-High Accuracy – Micron-level positioning precision

Enhanced Rigidity – Supports heavy spindle and worktable loads

Smooth Motion – Low friction and minimal vibration

Extended Lifespan – Hardened raceways and heat-treated steel

Reduced Maintenance – Lubrication systems minimize downtime

Faster Operation – Enables higher feed rates and machining speeds

Noise Reduction – Quiet rolling motion ensures a cleaner working environment

These advantages make YH Linear’s rails a trusted component in CNC engineering worldwide.

Types of CNC Linear Rails

Ball-Type Rails: Ideal for high-speed, light-to-medium load applications

Roller-Type Rails: Designed for high rigidity and heavy-load CNC setups

Miniature Rails: Suitable for compact, precision instruments

Wide Rails: Provide stability against torsional moments in multi-axis CNC machines

YH Linear offers all variants in custom lengths, preload grades, and accuracy classes.

Performance Features of YH Linear Rails

| Feature | Description |

|---|---|

| Precision Grade | Up to ±0.003 mm repeatability |

| Speed Rating | Up to 5 m/s travel speed |

| Load Capacity | High static and dynamic load limits |

| Noise Level | <50 dB under operation |

| Lubrication System | Self-lubricating or manual grease fitting |

Every YH Linear rail undergoes rigidity and smoothness testing before delivery.

Material Quality and Heat Treatment

The secret to YH Linear’s durability lies in material integrity:

SUJ2 Alloy Steel – For strength and hardness

SUS440C Stainless Steel – For corrosion resistance

Chrome and Nickel Plating – For surface protection

Black Oxide Coating – For wear resistance and reduced glare

Rails are vacuum heat-treated, ground to micron tolerances, and polished for smooth rolling contact.

Installation and Alignment Guidelines

Ensure the mounting base flatness within 0.02 mm.

Clean all contact surfaces before installation.

Align rails using precision measuring tools.

Tighten bolts in sequence to prevent distortion.

Test movement for smooth travel before operation.

Proper setup guarantees optimal CNC performance and rail lifespan.

Lubrication and Maintenance Tips

Lubrication prevents metal wear and noise. YH Linear recommends:

Lithium or synthetic grease for standard conditions

Oil-based lubrication for high-speed CNC systems

Reapplication every 500–1000 hours depending on workload

Built-in grease ports simplify the maintenance process, reducing downtime.

Comparison: Linear Rails vs Round Shaft Guides

| Feature | Linear Rails | Round Shafts |

|---|---|---|

| Accuracy | Very high | Moderate |

| Rigidity | Superior | Limited |

| Load Capacity | High | Low |

| Speed | High | Medium |

| Maintenance | Low | High |

| Vibration Resistance | Excellent | Average |

YH Linear’s rails outperform traditional guide systems, ensuring greater consistency and mechanical strength.

YH Linear’s Innovations in CNC Motion Technology

YH Linear integrates precision mechanics with intelligent engineering:

Advanced circulation path design reduces vibration

Low-noise structure enhances working comfort

Modular rail-block design enables easy replacement

Surface treatment improves corrosion and coolant resistance

Our innovative CNC linear rail systems set a new standard in motion control and machining accuracy.

Common Issues and Solutions in CNC Rail Systems

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Noise during movement | Misalignment or dry lubrication | Realign and lubricate |

| Rough motion | Contamination or debris | Clean and re-lubricate |

| Vibration | Overload or poor mounting | Check load limits and alignment |

| Corrosion | Humid environment | Use stainless or plated models |

Routine maintenance ensures your linear rails perform flawlessly for years.

Applications Across CNC Industries

YH Linear’s CNC linear rails are widely used in:

Milling Machines – Precision table guidance

CNC Lathes – Axis positioning stability

Engraving Machines – Smooth, detailed motion control

3D Printers – High-resolution linear motion

Laser Cutting Machines – Fast and consistent travel

Automation Equipment – Continuous high-speed operation

Our products drive precision and efficiency across multiple industries.

Customization and OEM Options by YH Linear

We offer complete customization for global CNC clients, including:

Custom rail lengths and hole spacing

Unique preload and tolerance adjustments

Special coatings for harsh environments

Co-branded OEM services and technical support

Visit https://yhlinear.com/ to discuss your custom motion system needs.

Quality Certifications and Testing Standards

Every YH Linear CNC rail is manufactured under:

ISO 9001 Quality Management

CE Certification

Strict In-House QC and Micron-Level Inspection

Each batch undergoes dimensional verification, noise analysis, and smoothness testing.

Sustainability in CNC Manufacturing

YH Linear integrates sustainability in every stage of production:

Use of recyclable materials

Eco-friendly plating and low-waste systems

Energy-efficient production lines

We are committed to delivering precision with environmental responsibility.

The Future of CNC Linear Rail Technology

The next evolution in CNC rail systems involves smart, connected technologies:

IoT-based sensors for monitoring wear and temperature

AI-driven predictive maintenance

Self-lubricating coatings for zero-maintenance systems

Lightweight carbon-composite designs

YH Linear continues to innovate for the next generation of intelligent CNC motion control.

Frequently Asked Questions

What is the role of linear rails in CNC machines?

They ensure smooth, precise, and stable linear motion during machining operations.

Are YH Linear rails compatible with major CNC brands?

Yes, our rails are interchangeable with most global CNC systems.

How often should I lubricate CNC rails?

Typically every 500–1000 operational hours, depending on the environment.

Do YH Linear rails resist coolant corrosion?

Yes, our stainless steel and plated models are coolant-resistant.

Where can I buy YH Linear CNC rails?

Visit https://yhlinear.com/ for models, specs, and purchasing options.

Conclusion

In CNC machining, linear rails CNC systems define precision, durability, and performance.

At YH Linear, our mission is to create rail systems that exceed expectations — delivering accuracy, longevity, and innovation for every machine and every motion.

From small-scale automation to industrial-grade CNC centers, YH Linear rails ensure your machinery performs with unrivaled precision and reliability.

👉 Learn more or request a quote at https://yhlinear.com/.

Suggested Inbound and Outbound Links

Inbound Links (YH Linear site):

Outbound Links: