Outline for “Heavy Duty Linear Guide Rails”

| Section | Subtopics |

|---|---|

| Introduction | The importance of heavy-duty linear guide rails in precision motion engineering |

| Understanding Heavy Duty Linear Guide Rails | What they are and how they differ from standard rails |

| Core Functions and Applications | From CNC machines to industrial automation |

| YH Linear’s Engineering Excellence | Why YH Linear sets global benchmarks |

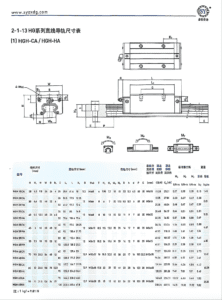

| Design Structure and Components | Rail, carriage, ball circulation system, and preload mechanisms |

| Advantages of Heavy-Duty Linear Rails | Rigidity, load capacity, and long-term reliability |

| Material Composition and Surface Treatments | Stainless, hardened steel, and protective coatings |

| Performance in Harsh Industrial Environments | Resistance to vibration, temperature, and corrosion |

| Installation and Setup Tips | Best practices for optimal accuracy |

| YH Linear’s Advanced Manufacturing Process | Precision machining, heat treatment, and inspection |

| Comparing Heavy-Duty vs. Standard Rails | Key performance differences |

| Custom Solutions from YH Linear | Tailored designs for specialized industries |

| Applications in Robotics and CNC Machinery | Improving performance in automated systems |

| Durability Testing and Quality Assurance | How YH Linear guarantees reliability |

| Maintenance Guidelines | Lubrication and inspection intervals |

| Troubleshooting Common Issues | Alignment, noise, and wear solutions |

| Eco-Friendly Production at YH Linear | Sustainability in manufacturing |

| Future Trends in Linear Rail Technology | Smart sensors, predictive maintenance, and composites |

| FAQs | Common questions and answers |

| Conclusion | Final thoughts and call to action |

| Suggested SEO Links | Internal and external link suggestions |

Heavy Duty Linear Guide Rails

Precision, strength, and reliability — these are the defining characteristics of heavy duty linear guide rails.

They are essential components in industries where machinery must operate under extreme load conditions without sacrificing accuracy or speed.

At YH Linear (https://yhlinear.com/), we specialize in designing and manufacturing heavy-duty linear guide rails that outperform in every industrial application — from CNC machining to robotic automation.

Understanding Heavy Duty Linear Guide Rails

Heavy duty linear guide rails are linear motion systems designed to support high loads, reduce friction, and ensure smooth, precise movement.

Unlike standard linear rails, heavy-duty variants are built with reinforced structures, wider contact surfaces, and high-load bearing blocks to handle static and dynamic forces effectively.

Their main purpose is to guide moving components — such as machine carriages or robotic arms — with consistent precision, even in high-vibration or high-temperature environments.

Core Functions and Applications

Heavy duty linear rails serve a wide range of applications, including:

CNC machining centers (metal cutting, milling, drilling)

Automated production lines

Injection molding machines

Packaging and logistics equipment

Robotic assembly systems

Medical imaging and precision instruments

They enable high-speed movement and repeatable accuracy, which are crucial in maintaining manufacturing quality and productivity.

YH Linear’s Engineering Excellence

YH Linear has become synonymous with engineering precision and industrial innovation.

Every product is built under ISO-certified facilities, ensuring global quality standards.

Our heavy-duty guide rails incorporate advanced features such as:

Multi-directional load-bearing design

Zero-clearance preloading for high rigidity

Optimized ball circulation channels for smooth travel

Anti-corrosion coatings for harsh environments

Seamless interchangeability with international brands

By focusing on precision manufacturing and consistent performance, YH Linear has earned the trust of global CNC and automation companies.

Design Structure and Components

| Component | Description |

|---|---|

| Rail | The linear track, made from hardened steel with a ground surface for precision alignment. |

| Carriage (Slider Block) | Houses rolling elements that transfer load evenly. |

| Rolling Elements (Balls/Rollers) | Enable frictionless motion between rail and block. |

| End Caps & Seals | Protect against dust and maintain lubrication. |

| Preload Mechanism | Ensures zero clearance and improved rigidity. |

Each part of a YH Linear rail system is CNC-machined and laser-verified for dimensional accuracy.

Advantages of Heavy-Duty Linear Rails

Extreme Load Capacity: Engineered to carry both static and dynamic loads.

High Rigidity: Provides resistance to bending or deflection.

Smooth and Silent Operation: Thanks to precision-ground raceways.

Longer Lifespan: Enhanced durability from heat-treated components.

Corrosion Resistance: Ideal for humid or chemical environments.

Easy Installation: Interchangeable with major linear rail standards.

These attributes make YH Linear’s rails the preferred choice for manufacturers seeking consistency and performance.

Material Composition and Surface Treatments

YH Linear uses premium materials to ensure endurance and accuracy:

High-Carbon Chrome Steel (SUJ2): For wear resistance.

SUS440C Stainless Steel: For cleanrooms and corrosive conditions.

Chromium and Nickel Coatings: Enhance anti-rust capabilities.

Black Oxide Finish: Adds surface protection and reduces glare.

Each rail undergoes heat treatment to achieve optimal hardness without compromising toughness.

Performance in Harsh Industrial Environments

Heavy duty guide rails from YH Linear are designed to withstand extreme conditions such as:

Continuous vibration from CNC milling

High-speed operation in automation lines

Temperature fluctuations in industrial plants

Dust, moisture, and chemical exposure

With sealed carriage systems and precision-ground surfaces, they maintain consistent performance in any environment.

Installation and Setup Tips

To maximize accuracy and lifespan:

Ensure mounting surface flatness within ±0.02 mm.

Use a torque wrench for even bolt tightening.

Apply lubrication before initial use.

Verify parallelism between dual rails.

Test travel smoothness before full operation.

Proper setup ensures long-term reliability and minimal wear.

YH Linear’s Advanced Manufacturing Process

From raw steel selection to final assembly, YH Linear follows a rigorous multi-step process:

Precision CNC machining

Heat treatment and stress relief

Surface grinding and polishing

Ultra-fine cleaning and inspection

Assembly under controlled conditions

Final testing for preload, noise, and vibration

This ensures every YH Linear heavy-duty guide rail exceeds global performance benchmarks.

Comparing Heavy-Duty vs. Standard Rails

| Feature | Heavy-Duty Rails | Standard Rails |

|---|---|---|

| Load Capacity | Up to 4× higher | Standard |

| Rigidity | Excellent | Moderate |

| Operating Life | Extended | Normal |

| Maintenance | Low | Moderate |

| Ideal Use | CNC, robotics, industrial lines | Light automation |

YH Linear’s heavy-duty models are specifically engineered for precision-critical, load-intensive environments.

Custom Solutions from YH Linear

We understand that every project has unique needs.

That’s why YH Linear offers custom rail solutions, including:

Special sizes and lengths

Custom mounting holes

Coating and surface finish options

OEM and ODM services

Our design engineers collaborate with clients to ensure perfect system integration.

Applications in Robotics and CNC Machinery

Heavy-duty rails are the core motion elements in robotic arms and CNC axes.

They ensure movement precision down to microns, allowing faster cycle times and superior machining quality.

YH Linear’s rails are widely used in:

Robotic assembly cells

5-axis machining centers

Semiconductor automation

Automated inspection systems

Their rigidity and smooth operation improve both performance and efficiency.

Durability Testing and Quality Assurance

Every YH Linear guide rail undergoes:

Fatigue testing for over 10 million cycles

Load endurance trials under extreme force

Corrosion resistance tests in salt spray environments

Dimensional verification using CMM inspection

This guarantees repeatable precision and operational longevity.

Maintenance Guidelines

To keep your rails in perfect condition:

Re-lubricate every 1000–2000 hours.

Keep the environment clean and dust-free.

Inspect preload and mounting bolts regularly.

Use original YH Linear lubricants and seals.

Proper maintenance prevents premature wear and noise issues.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Noise during motion | Misalignment | Recalibrate rail installation |

| Uneven movement | Contamination | Clean and re-lubricate |

| Excessive wear | Overload | Reduce load or switch to roller type |

| Corrosion | Humidity | Use stainless variants |

Simple preventive checks can save costly downtime.

Eco-Friendly Production at YH Linear

YH Linear is committed to sustainable practices:

Energy-efficient CNC machining

Waste oil recycling systems

Low-emission coating technologies

Eco-friendly packaging materials

We believe precision engineering and environmental responsibility can go hand in hand.

Future Trends in Linear Rail Technology

The future of linear motion lies in smart, self-monitoring systems.

YH Linear is developing:

Rails with integrated sensors

Predictive maintenance software

Composite and hybrid materials

Low-friction nano-coatings

These innovations will redefine efficiency and durability in industrial automation.

FAQs

What are heavy duty linear guide rails used for?

They are used in machines that require high precision under heavy loads — such as CNCs, robots, and production equipment.

Are YH Linear rails compatible with other brands?

Yes, YH Linear rails follow international standards and can replace global models easily.

How often should heavy-duty rails be lubricated?

Every 1000–2000 operating hours, depending on the environment.

Can they operate in high-temperature environments?

Yes, with appropriate material and lubrication options.

Where can I purchase YH Linear guide rails?

Visit https://yhlinear.com/ for direct support and distributor details.

Conclusion

Heavy duty linear guide rails are essential for maintaining precision and stability in industrial systems — and YH Linear stands at the forefront of this innovation.

Through cutting-edge design, quality materials, and unmatched reliability, YH Linear delivers the performance and longevity that modern industries demand.

Explore more about our heavy-duty rail systems at 👉 https://yhlinear.com/

Suggested SEO Links

Inbound Links (YH Linear site):

Outbound Links: