Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Slide Guide Rail | linear rail system |

| What Is a Linear Slide Guide Rail | linear motion rail |

| Core Components of a Linear Slide Guide Rail | rail, carriage, bearings |

| Working Mechanism of Linear Slide Guide Rail | rolling elements, friction reduction |

| Benefits of Linear Slide Guide Rail | accuracy, load capacity |

| Types of Linear Slide Guide Rail | ball rail, roller rail |

| Miniature Linear Slide Guide Rail | compact motion systems |

| Heavy-Duty Linear Slide Guide Rail | industrial motion |

| Selecting the Right Linear Slide Guide Rail | load, precision, materials |

| Common Applications of Linear Slide Guide Rail | CNC, automation |

| Installation Best Practices | alignment, mounting |

| Maintenance Tips | lubrication, cleanliness |

| Common Problems & Troubleshooting | noise, vibration |

| Material Options for Linear Slide Guide Rail | stainless steel, bearing steel |

| Linear Slide Guide Rail vs Linear Shafts | comparison |

| Environmental Considerations | dust, moisture |

| YH Linear Slide Guide Rail Expertise | OEM, customization |

| Innovations in Linear Guide Rail Technology | smart lubrication |

| FAQs | lifespan, lubrication |

| Conclusion | performance, reliability, precision |

Introduction to Linear Slide Guide Rail

In modern automation and precision engineering, the linear slide guide rail plays an essential role in delivering smooth, accurate motion. Whether used in CNC machines, robotics, or advanced production equipment, this rail system ensures reliable linear movement with minimal friction. The demand for efficiency, speed, and accuracy has made the linear slide guide rail one of the most critical components in today’s industrial systems.

What Is a Linear Slide Guide Rail

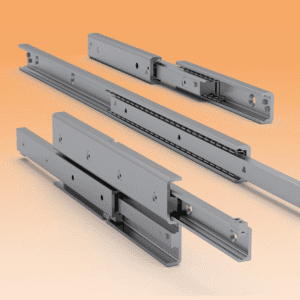

A linear slide guide rail is a mechanical device designed to guide motion along a straight path. It consists of a hardened steel rail and a carriage (block) containing rolling elements such as ball bearings or rollers.

The system transforms sliding friction into smooth rolling movement, enabling precise positioning and high rigidity. The linear slide guide rail outperforms traditional bushings or dovetail slides due to its low friction, high load capacity, and exceptional repeatability.

Core Components of a Linear Slide Guide Rail

A complete linear slide guide rail system includes:

Guide Rail: Provides a hardened track for motion.

Carriage / Block: Moves along the rail and holds rolling elements.

Rolling Elements: Balls or rollers that enable smooth motion.

End Caps & Scrapers: Keep contaminants away from the rolling mechanism.

Lubrication Ports: Ensure proper grease distribution.

Each component contributes to stability and precision during movement.

Working Mechanism of Linear Slide Guide Rail

The linear slide guide rail operates on a rolling contact principle. As the carriage moves, the rolling elements continuously recirculate between the rail and block.

This design provides:

Extremely low friction

Minimal wear

High repeatability

Smooth and stable linear travel

The precision of the rail and carriage allows machinery to maintain accurate motion even under constant or fluctuating loads.

Benefits of Linear Slide Guide Rail

Using a linear slide guide rail offers several notable advantages:

High Precision: Ensures accurate linear movement for industrial processes.

Superior Rigidity: Supports heavy loads with minimal deflection.

Low Friction: Reduces heat and energy consumption.

High-Speed Capability: Suitable for fast-moving automation systems.

Long Lifespan: Hardened materials ensure durability.

Easy Installation: Rails can be mounted on a variety of surfaces.

These benefits make them ideal for demanding environments requiring consistent performance.

Types of Linear Slide Guide Rail

There are several major linear slide guide rail types, each designed for different performance requirements:

Ball Type Linear Slide Guide Rail

Uses recirculating balls for smooth, low-friction operation.

Ideal for CNC machines, 3D printers, and automation equipment.

Roller Type Linear Slide Guide Rail

Uses cylindrical rollers to increase rigidity and load capacity.

Perfect for heavy-duty machining and industrial equipment.

Cross Roller Type Linear Guide

Arranges rollers in an alternating pattern for ultra-smooth movement.

Common in metrology equipment and optical devices.

Miniature Linear Slide Guide Rail

Compact design for small devices like laboratory equipment and medical imaging systems.

Miniature Linear Slide Guide Rail

Miniature versions of the linear slide guide rail are designed for lightweight loads and precision applications.

Features:

Small form factor

High accuracy in tight spaces

Smooth motion with minimal vibration

Applications:

Semiconductor processing

Micro-robotics

Compact CNC machines

Engineers choose miniature rails when space and accuracy are both critical.

Heavy-Duty Linear Slide Guide Rail

For industrial use, heavy-duty linear slide guide rails offer exceptional strength and stability.

Features:

Reinforced rail structure

Larger rolling elements

High shock resistance

Enhanced rigidity

Applications:

CNC machining centers

Injection molding machines

Material-handling systems

These rails excel in environments where performance and durability must withstand tough conditions.

Selecting the Right Linear Slide Guide Rail

When choosing a linear slide guide rail, consider these important factors:

| Factor | Importance |

|---|---|

| Load Capacity | Must support static and dynamic forces |

| Precision | Determines accuracy level |

| Speed | Affects choice of rolling elements |

| Environment | Heat, dust, chemicals |

| Material | Stainless or bearing steel |

| Mounting Type | Impacts rigidity |

Selecting the right rail ensures longevity and high system performance.

Common Applications of Linear Slide Guide Rail

The linear slide guide rail is used across many industries:

CNC Milling and Turning Machines

3D Printers and Laser Cutters

Robotic Arms and Automation Lines

Medical Imaging Systems

Packaging Machinery

Semiconductor Equipment

Its versatility makes it essential in any system requiring smooth linear motion.

Installation Best Practices

To ensure maximum performance from your linear slide guide rail, follow these guidelines:

Keep mounting surfaces clean and flat.

Align rails precisely to prevent uneven wear.

Use appropriate torque when tightening screws.

Avoid contamination during installation.

Check carriage motion before operation.

Proper installation ensures long-lasting precision.

Maintenance Tips

Maintaining a linear slide guide rail is simple but critical:

Clean rails regularly to remove dust and debris.

Lubricate following manufacturer guidelines.

Inspect rolling elements for smoothness.

Replace damaged seals immediately.

Avoid moisture exposure when possible.

Routine maintenance extends the life of your rail system.

Common Problems & Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| Vibration | Misalignment | Reinstall or realign |

| Rough Motion | Lack of lubrication | Apply grease or oil |

| Noise | Contamination | Clean block and rail |

| Corrosion | Humidity exposure | Choose stainless steel |

Most issues can be resolved through proper installation and care.

Material Options for Linear Slide Guide Rail

Different environments require different materials:

Bearing Steel (SUJ2): High rigidity and durability

Stainless Steel: Corrosion-resistant

Chrome-Plated Steel: Protects against rust

Black Oxide Coating: Reduces glare and corrosion

Choosing the right material ensures optimal performance under various conditions.

Linear Slide Guide Rail vs Linear Shafts

| Feature | Linear Slide Guide Rail | Linear Shaft |

|---|---|---|

| Precision | High | Moderate |

| Load Capacity | High | Light–medium |

| Rigidity | Very high | Low |

| Cost | Higher | Lower |

| Best Use | CNC & robotics | Light automation |

Rails outperform shafts when accuracy and rigidity matter most.

Environmental Considerations

A linear slide guide rail must withstand environmental factors such as:

Dust

Moisture

Chemicals

Extreme temperatures

Sealed blocks, stainless steel rails, and protective coatings help maintain performance even in harsh environments.

YH Linear: Trusted Linear Slide Guide Rail Manufacturer

YH Linear provides high-quality linear slide guide rails compatible with CNC machines, automation systems, robotics, and industrial machinery.

Why Choose YH Linear?

OEM & ODM customization

ISO-certified manufacturing

Precision grinding and heat treatment

Competitive pricing for global clients

Fast delivery and technical support

YH Linear ensures accuracy, durability, and consistency in every rail.

Innovations in Linear Guide Rail Technology

Modern linear slide guide rail systems feature exciting innovations:

Self-lubricating designs

Smart monitoring sensors

Low-noise rolling elements

Micro-polished rail surfaces

Lightweight carriage designs

These upgrades improve efficiency and reduce long-term maintenance costs.

FAQs

What is a linear slide guide rail used for?

It provides precise, low-friction motion for CNC machines, robots, and automation equipment.

Do linear slide guide rails require lubrication?

Yes, regular lubrication ensures smooth operation and prevents wear.

Are linear rails interchangeable?

Some brands follow standard dimensions, but compatibility must be confirmed.

How long does a linear slide guide rail last?

With proper care, rails can last millions of motion cycles.

Can they handle heavy loads?

Yes, heavy-duty versions are engineered for industrial loads.

Conclusion

The linear slide guide rail is essential for precision motion across countless industries. Its strength, rigidity, and accuracy make it a reliable solution for CNC machines, automation systems, robotics, and high-tech devices. With advanced engineering and dependable performance, these rails continue to support innovation and efficiency in modern manufacturing.

Inbound Link Suggestions

Outbound Link Suggestions

THK Motion Systems

HIWIN Linear Guideways

Bosch Rexroth Linear Technology