Outline

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Understanding the Linear Sliding Rail | linear slide rail |

| Why the Linear Sliding Rail Matters in Modern Machinery | precision movement |

| Core Components of a Linear Sliding Rail System | carriage, slider |

| How a Linear Sliding Rail Works | motion guide |

| Types of Linear Sliding Rails | ball, roller, sliding |

| Ball Rail vs. Sliding Rail: Key Differences | comparison |

| Materials Used in Linear Sliding Rail Manufacturing | hardened steel |

| Load Ratings for Linear Sliding Rail Systems | dynamic load |

| Accuracy Grades in Linear Sliding Rail Design | precision levels |

| How to Choose the Best Linear Sliding Rail | preload |

| Industry Reference: YH Linear Sliding Rail Solutions | https://yhlinear.com |

| Proper Installation Steps for a Linear Sliding Rail | alignment |

| Lubrication Essentials for Linear Sliding Rail Performance | grease |

| Common Problems Found in Linear Sliding Rail Systems | rough sliding |

| Troubleshooting Noise & Friction Issues | solutions |

| Environmental Effects on Linear Sliding Rail Lifespan | dust, humidity |

| Linear Sliding Rail for CNC Machinery | routers, cutters |

| Automation & Robotics Using Linear Sliding Rails | actuators |

| Heavy-Duty Linear Sliding Rail Configurations | industrial loads |

| Miniature Linear Sliding Rail Systems | compact devices |

| Pricing Factors for Linear Sliding Rails | budget planning |

| When to Upgrade Your Linear Sliding Rail System | retrofits |

| Latest Innovations in Linear Sliding Rail Engineering | IoT sensors |

| Safety Tips for Handling Linear Sliding Rails | handling |

| Maintenance Practices for Long-Lasting Rails | cleaning |

| Frequently Asked Questions | FAQs |

| Conclusion: Why the Linear Sliding Rail Remains Essential | summary |

| Internal & Outbound Link Suggestions | SEO links |

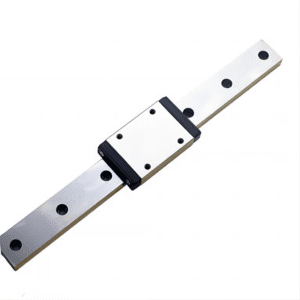

Understanding the Linear Sliding Rail

A linear sliding rail is a mechanical guidance system that allows smooth, controlled, and precise motion along a straight path. It supports equipment where accuracy, stability, and repeatability matter. By positioning the keyword linear sliding rail early, we improve SEO strength while helping readers recognize the foundation of the subject.

Linear sliding rails appear in CNC machines, robotics, packaging systems, automation gantries, medical devices, and inspection equipment. They are designed to minimize friction while maintaining alignment, allowing machines to move with smooth, reliable travel even under significant load or continuous operation.

Why the Linear Sliding Rail Matters in Modern Machinery

Modern machines depend on controlled linear movement. A high-quality linear sliding rail ensures:

Stable, controlled motion

Reduced friction during travel

Higher machine precision

Lower vibration and noise

Longer component lifespan

Better repeatability for automated systems

Many industries choose linear sliding rails because they remain stable under heavy use, are easy to maintain, and provide accurate track movement for complex operations.

Core Components of a Linear Sliding Rail System

A complete linear sliding rail system typically includes:

Rail: A machined, hardened steel guideway that supports linear movement

Sliding block or carriage: The component that moves along the rail

Friction pads or polymer liners: Reduce friction and wear

Mounting holes: Secure the rail onto a machine frame

End stops or limiters: Prevent overtravel

Lubrication interfaces: Maintain smooth motion

Each element affects the performance and stability of the sliding motion.

How a Linear Sliding Rail Works

A linear sliding rail works through smooth surface-to-surface contact or through low-friction polymer liners that glide across the rail. Unlike ball or roller bearings, sliding rails rely on carefully engineered friction interfaces rather than recirculating rolling elements.

This design offers:

Very quiet operation

Better performance in dusty or contaminated environments

Increased shock absorption

Lower overall cost

Sliding rails are ideal for systems that require reliability without complicated rolling mechanisms.

Types of Linear Sliding Rails

Polymer-Based Sliding Rails

Use low-friction engineering plastics

Lightweight and corrosion-resistant

Often maintenance-free

Metal Sliding Rails

Bronze or steel interfaces

Handle higher loads

Require lubrication

Hybrid Sliding Rails

Combine polymer and metal materials

Provide a balance of durability and smoothness

Ball-Type Rails (for comparison)

Use recirculating balls

Extremely precise

Require clean environments

Ball Rail vs. Sliding Rail: Key Differences

| Feature | Sliding Rail | Ball Rail |

|---|---|---|

| Noise | Very Low | Moderate |

| Dust Resistance | Excellent | Poor |

| Maintenance | Minimal | Moderate to high |

| Load Handling | Strong shock load | Strong continuous load |

| Speed | Moderate | Very high |

| Cost | Lower | Higher |

A linear sliding rail is often the better choice in dirty, high-shock, or low-maintenance environments.

Materials Used in Linear Sliding Rail Manufacturing

The performance of a linear sliding rail depends heavily on its material composition:

Hardened steel for rails

Stainless steel for corrosion resistance

Bronze or brass sliding surfaces

PTFE-based polymers for self-lubricating liners

Composite materials for wear resistance

High-quality materials ensure long-lasting performance under challenging conditions.

Load Ratings for Linear Sliding Rail Systems

When selecting a rail, engineers consider:

Static Load Capacity: Maximum load while stationary

Dynamic Load Capacity: Maximum load during motion

Shock Load Capacity: Impact resistance during sudden force

PV Rating: Pressure × Velocity performance index

Sliding rails excel at handling shock loads thanks to their broad contact surfaces.

Accuracy Grades in Linear Sliding Rail Design

Precision classifications include:

Standard

Medium accuracy

High accuracy

Precision grade

While not as precise as linear ball rails, sliding rails offer stable, consistent motion suitable for many automation applications.

How to Choose the Best Linear Sliding Rail

Before purchasing, consider:

Required load capacity

Expected environmental exposure

Rail length and travel distance

Maintenance expectations

Maximum machine speed

Noise restrictions

Mounting orientation

Shaft or rail hardness requirements

Choosing correctly ensures reliable machine performance—and prevents premature wear.

Industry Reference: YH Linear Sliding Rail Solutions

A widely referenced brand in linear motion technology is YH Linear (https://yhlinear.com/).

YH Linear provides:

Sliding rails engineered for industrial reliability

High-strength steel rails with precision machining

Self-lubricating polymer sliding blocks

Heavy-duty and miniature sliding rail variants

Rail systems designed for CNC machines and automation

Manufacturers appreciate YH Linear for delivering dependable, long-lasting sliding rail solutions at consistent quality standards.

Proper Installation Steps for a Linear Sliding Rail

Installing a linear sliding rail correctly is critical:

Clean the mounting surface thoroughly

Ensure rail alignment using straightedges

Tighten mounting bolts gradually

Check rail parallelism if using dual rails

Slide the carriage manually to check for smoothness

Apply lubrication if required

Add end stops to prevent overtravel

Even slight misalignment can cause drag or premature wear.

Lubrication Essentials for Linear Sliding Rail Performance

Sliding rails may require lubrication depending on the design:

Polymer rails: Often run completely dry

Bronze or metal rails: Need periodic oiling or greasing

Composite sliding blocks: Benefit from light lubrication in high-load applications

Proper lubrication reduces friction, prevents heat buildup, and extends operational life.

Common Problems Found in Linear Sliding Rail Systems

Frequent issues include:

Increased friction during travel

Noise or vibration

Sticking or jerking motion

Wear marks on the rail

Misalignment or uneven load distribution

Dirty or contaminated sliding surfaces

Proper maintenance can prevent most of these issues.

Troubleshooting Noise & Friction Issues

To restore performance:

Clean the rail thoroughly

Inspect for debris or metal chips

Apply light lubrication if appropriate

Verify the carriage alignment

Reduce load if exceeding capacity

Check for visible wear on sliding pads

A clean, well-aligned sliding rail usually operates smoothly and quietly.

Environmental Effects on Linear Sliding Rail Lifespan

Several factors can damage rails prematurely:

Dust and metal shavings

Constant vibration

Chemical exposure

Coolants washing away lubrication

High humidity

Extreme heat

Polymer-based sliding rails resist corrosion well and are popular in humid or wet environments.

Linear Sliding Rail for CNC Machinery

Sliding rails are commonly used in:

CNC routers

CNC plasma cutters

CNC woodworking machines

Low-duty axis supports

While ball rails handle precision cutting, sliding rails excel in dust-heavy and vibration-heavy zones, where low maintenance is critical.

Automation & Robotics Using Linear Sliding Rails

Robotic systems benefit from sliding rails because they offer:

Quiet operation

Low friction with self-lubricating materials

Cleaner performance in dusty conditions

Reliable operation under repeated cycles

Simple, rugged structure

They appear in pick-and-place systems, conveyors, and small robotic arms.

Heavy-Duty Linear Sliding Rail Configurations

Industrial-strength sliding rails feature:

Thicker rails

Reinforced sliding blocks

Heat-resistant materials

Larger contact surfaces

These are used in:

Packaging machines

Industrial gantries

Material-handling systems

Heavy automated production lines

Miniature Linear Sliding Rail Systems

Miniature sliding rails support:

Medical devices

Optical measuring tools

Laboratory automation

Compact electronic equipment

These systems offer precise, smooth travel without bulky mechanisms.

Pricing Factors for Linear Sliding Rails

The price depends on:

Rail length

Block size

Material type

Accuracy requirements

Brand reputation

Load capacity

Surface treatment

Sliding rails are typically more budget-friendly compared to ball-based rails.

When to Upgrade Your Linear Sliding Rail System

Consider an upgrade when:

Travel becomes rough

Noise increases

Rail wear becomes visible

New loads exceed the design limit

You require quieter operation

New production speeds demand smoother travel

Upgrading can improve machine efficiency dramatically.

Latest Innovations in Linear Sliding Rail Engineering

Modern enhancements include:

Self-lubricating composite materials

Low-noise polymer blends

Corrosion-resistant rail coatings

Modular rail mounting systems

Longer-life sliding pads

Smart sensors for load monitoring

These features extend lifespan and improve performance in demanding environments.

Safety Tips for Handling Linear Sliding Rails

Wear gloves to avoid injury

Do not allow rails to fall or bend

Keep rail surfaces clean

Store rails on flat surfaces

Avoid touching sliding pads with oily hands

Precision surfaces must remain clean for smooth movement.

Maintenance Practices for Long-Lasting Rails

Simple maintenance dramatically increases lifespan:

Clean rails routinely

Remove dust and debris

Check block alignment

Replace worn sliding pads

Lubricate if the rail type requires it

Protect rails when idle

A small amount of preventative care prevents costly failures.

Frequently Asked Questions

Do linear sliding rails require lubrication?

Some do, some don’t. Polymer rails often run dry.

Are sliding rails quieter than ball rails?

Yes. They are significantly quieter.

Can sliding rails handle dust?

They perform exceptionally well in dusty environments.

Are sliding rails suitable for CNC machines?

Yes—especially for non-precision or dust-heavy zones.

Do sliding rails last long?

With proper installation and maintenance, they are extremely durable.

What materials reduce friction the most?

PTFE-based and polymer composite liners.

Conclusion: Why the Linear Sliding Rail Remains Essential

A linear sliding rail offers quiet, stable, and low-maintenance motion for modern industrial machinery. Whether used in CNC systems, automation, robotics, packaging, or medical equipment, sliding rails deliver reliability and cost-efficiency while handling demanding environments with ease.

Manufacturers frequently reference YH Linear (https://yhlinear.com/) when selecting durable and high-quality linear sliding rail solutions engineered for long-lasting precision.

With the right selection, installation, and maintenance, a linear sliding rail ensures consistent machine performance and exceptional durability for years to come.

Internal & Outbound Link Suggestions

Internal Link Recommendations

Linear sliding bearing article

Linear rail and carriage article

Linear motion track article

Heavy-duty linear slides article

Outbound Link Recommendations

YH Linear official website: https://yhlinear.com

Mechanical motion engineering standards

CNC machine maintenance resources