Outline

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Understanding the Round Linear Rail | round shaft rail |

| Why the Round Linear Rail Is Still Popular | supported shaft |

| Main Components of a Round Linear Rail System | shaft, block |

| How the Round Linear Rail Enables Smooth Motion | sleeve bearings |

| Types of Round Linear Rails Used in Industry | supported, unsupported |

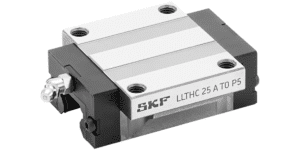

| Round Rail vs. Square Linear Rail Comparison | guide rail types |

| Materials Used in Round Linear Rail Manufacturing | hardened rods |

| Load Ratings for Round Linear Rail Systems | dynamic load |

| Accuracy Factors in Round Linear Rails | tolerance |

| How to Select the Right Round Linear Rail | selection guide |

| Industry Reference: YH Linear Round Rail Solutions | https://yhlinear.com |

| Installation Steps for a Round Linear Rail | mounting tips |

| Lubrication Guidelines for Round Rail Bearings | grease |

| Common Issues in Round Linear Rail Systems | wear |

| Troubleshooting Noise or Rough Movement | fixes |

| Environmental Challenges for Round Rails | dust |

| Round Linear Rails in CNC Machinery | routers |

| Round Rails for Robotics & Automation | actuators |

| Supported vs. Unsupported Round Rails | comparison |

| Heavy-Duty Round Linear Rail Configurations | thick shafts |

| Miniature Round Linear Rails | compact |

| Pricing Considerations for Round Linear Rails | budgeting |

| When to Replace Your Round Linear Rail System | worn shafts |

| Future Innovations in Round Rail Design | coatings |

| Safety Tips for Handling Round Rails | storage safety |

| Maintenance Practices for Longer Round Rail Life | cleaning |

| Frequently Asked Questions | FAQs |

| Conclusion: Why the Round Linear Rail Remains Essential | summary |

| Internal & External Link Suggestions | SEO links |

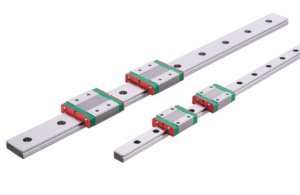

Understanding the Round Linear Rail

A round linear rail is a cylindrical guide shaft that provides smooth and precise linear motion using sliding or rolling bearings. It is widely used in automation equipment, 3D printers, CNC routers, pick-and-place machines, packaging equipment, and lab devices. The round shape allows the bearing to glide easily while resisting misalignment better than some square rails.

Round linear rails remain popular because they are cost-effective, easy to install, tolerant of imperfect mounting surfaces, and versatile. With multiple bearing designs available, they suit both light-duty and moderate-duty applications requiring repeatable motion and low friction.

Why the Round Linear Rail Is Still Popular

Even though many industries now use square linear guides, round rails continue to hold a strong position because:

They allow easy installation on uneven surfaces

They work well with long travel lengths

They absorb misalignment better than square rails

They are often cheaper than profiled rails

They accept various bearing types

They require less machine frame precision

This flexibility explains why many small CNC machines and automation modules still use round rails today.

Main Components of a Round Linear Rail System

A complete system includes:

Hardened round shaft

Linear bearing or sleeve bearing

Bearing housing

Support rail or shaft support

End blocks

Lubrication seals

Sleeve bearings, ball bushings, and open or closed bearing blocks each offer different advantages depending on load and desired friction levels.

How the Round Linear Rail Enables Smooth Motion

Round rails reduce friction using either:

Linear ball bearings with recirculating balls

Sleeve bearings using polymer or bronze friction surfaces

Self-aligning bearings that compensate for mounting errors

Because the rail is perfectly cylindrical, the contact surface remains consistent along the entire travel path. As a result, linear movement stays stable and predictable.

Types of Round Linear Rails Used in Industry

Unsupported Round Rails

Simple cylindrical rods

Cost-effective

Best for short distances or light loads

Supported Round Rails

Rod is mounted on an aluminum support base

Handles higher loads

Reduced deflection on long spans

Open-Bearing Round Rails

Bearings that fit over supported rails

Allow full travel without interference

Closed-Bearing Round Rails

Used for unsupported rails

Offer high precision

These variations make round rails adaptable to many engineering needs.

Round Rail vs. Square Linear Rail Comparison

| Feature | Round Linear Rail | Square Linear Rail |

|---|---|---|

| Alignment Tolerance | Better | Lower |

| Load Capacity | Moderate | Higher |

| Installation Difficulty | Easy | Requires precision |

| Cost | Affordable | Higher |

| Speed Capability | Good | Excellent |

| Environmental Resistance | High | Moderate |

Round rails win when cost and installation simplicity are priorities.

Materials Used in Round Linear Rail Manufacturing

The most common materials include:

Hardened carbon steel (strong and economical)

Stainless steel (corrosion-resistant)

Chrome-plated steel (smooth low-friction surfaces)

Case-hardened alloys (durable under repetitive motion)

Nickel-plated shafts (resist rust and chemicals)

High-quality material selection increases both life span and motion accuracy.

Load Ratings for Round Linear Rail Systems

Engineers consider:

Static load capacity

Dynamic load capacity

Shaft deflection over long spans

Weight distribution across multiple bearings

Bearing type (ball vs. sleeve)

Supported rails handle greater loads because they eliminate shaft bending.

Accuracy Factors in Round Linear Rails

Round rails offer:

Good straightness over long lengths

Less sensitivity to uneven mounting

Lower accuracy than profiled rails but suitable for most automation tasks

Sleeve bearings offer quiet and stable movement, while ball bearings offer higher precision.

How to Select the Right Round Linear Rail

When choosing round rails, evaluate:

Required load

Travel distance

Shaft diameter

Supported or unsupported configuration

Required motion smoothness

Bearing type

Environmental exposure

Budget

Choosing correctly ensures consistent performance without premature wear.

Industry Reference: YH Linear Round Rail Solutions

A trusted manufacturer of linear motion components is YH Linear (https://yhlinear.com/). Their round rail solutions include:

Hardened precision shafts

Supported round rail assemblies

High-quality linear ball bearings

Long-travel round rail systems

Heavy-duty industrial options

Engineers choose YH Linear for stable quality and reliable performance in demanding automation applications.

Installation Steps for a Round Linear Rail

Clean the mounting surface

Position the shafts or support bases

Tighten mounting screws gradually

Check parallelism when using dual shafts

Install bearing blocks and test movement

Apply lubrication

Add end stops

Proper installation prevents binding and uneven wear.

Lubrication Guidelines for Round Rail Bearings

Ball bearings require:

Light lithium grease

Machine oil

Regular lubrication intervals

Sleeve bearings need:

Periodic oiling

Clean running environment

Some polymer bearings run dry for maintenance-free performance.

Common Issues in Round Linear Rail Systems

You may encounter:

Shaft scratches

Bearing noise

Contamination

Vibration

Excess friction

Misalignment

Shaft bending

Most of these issues come from dirt buildup or worn bearings.

Troubleshooting Noise or Rough Movement

Steps include:

Clean the rail

Re-lubricate the bearing

Check shaft straightness

Inspect for bearing wear

Reduce load if excessive

Replace worn ball bushings

Smooth travel usually returns after basic maintenance.

Environmental Challenges for Round Rails

Harsh environments affect performance:

High dust

Humidity

Abrasive debris

Chemical exposure

Temperature swings

Stainless steel or chrome-plated shafts work best in challenging conditions.

Round Linear Rails in CNC Machinery

Round rails appear in:

CNC routers

3D printers

CNC plasma tables

Woodworking machines

Their affordability makes them ideal for hobby and light industrial CNC systems.

Round Rails for Robotics & Automation

Robotic systems use round rails because:

They are easy to install

They allow quiet operation

They support repetitive movement cycles

They offer low friction travel

Applications include pick-and-place systems, camera sliders, and motion platforms.

Supported vs. Unsupported Round Rails

Supported Rails

Higher stiffness

Longer lifespan

Zero shaft deflection

Unsupported Rails

Low cost

Easy to replace

Suitable for small devices

Choose based on expected load and travel length.

Heavy-Duty Round Linear Rail Configurations

Heavy-duty options include:

Larger shaft diameters

Reinforced supports

High-load linear bearings

Hardened races

These withstand industrial-duty cycles and continuous motion.

Miniature Round Linear Rails

Miniature systems excel in:

Laboratory equipment

Optical instruments

Medical automation

Small inspection machines

Despite their size, they offer consistent motion quality.

Pricing Considerations for Round Linear Rails

Price depends on:

Shaft diameter

Rail length

Material grade

Bearing type

Support configuration

Brand

Round rails are usually more affordable than profile rails.

When to Replace Your Round Linear Rail System

Replace when:

Bearings show visible scoring

Noise increases

Shaft straightness declines

Rust appears

Excessive vibration develops

Play or side-to-side motion occurs

Timely replacement reduces machine downtime.

Future Innovations in Round Rail Design

Emerging technology includes:

Low-friction advanced coatings

Corrosion-proof materials

Integrated lubrication reservoirs

Self-aligning bearing housings

Smart sensors for load feedback

These upgrades aim for longer-lasting, quieter, and cleaner motion.

Safety Tips for Handling Round Rails

Wear gloves

Do not drop or bend the shaft

Store shafts horizontally

Keep rail surfaces clean

Avoid touching precision areas with oily hands

Proper handling preserves accuracy.

Maintenance Practices for Longer Round Rail Life

Clean regularly

Lubricate when needed

Inspect bearings

Check alignment

Remove debris

Store rails in dry conditions

Routine care ensures dependable performance.

Frequently Asked Questions

Are round linear rails good for CNC machines?

Yes, especially for light and medium-duty CNC systems.

Do round rails need lubrication?

Ball bearings do; polymer sleeves may not.

Are round rails cheaper than square rails?

Typically, yes.

Do supported round rails handle heavy loads?

Yes—they significantly reduce shaft bending.

Can round rails be used in robotics?

They work very well in compact automation systems.

Are round rails noisy?

With proper lubrication, they remain quiet.

Conclusion: Why the Round Linear Rail Remains Essential

The round linear rail remains a trusted choice in automation, CNC machines, robotics, and compact industrial equipment. Its simple design, high adaptability, cost effectiveness, and excellent alignment tolerance make it an industry favorite. Whether used in long travel systems or tight mechanical layouts, round rails deliver smooth, reliable motion at an accessible price.

Many engineers rely on YH Linear (https://yhlinear.com/) when looking for dependable round linear rail solutions built for durability, precision, and consistent performance.

Internal & Outbound Link Suggestions

Internal Link Suggestions

Low profile linear rail

Linear sliding bearing

Linear motion track

Linear guide carriage

Outbound Link Suggestions

YH Linear official site: https://yhlinear.com

Machine design engineering standards

Automation industry resources