Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Linear Guide Slider Overview | linear motion slider, guide block |

| How a Linear Guide Slider Works | rolling elements, guide carriage |

| Core Components of a Linear Guide Slider | rail, slider block |

| Different Types of Linear Guide Slider Systems | linear blocks, rail guides |

| Ball-Type Linear Guide Slider | recirculating balls |

| Roller-Type Linear Guide Slider | linear roller slider |

| Linear Guide Slider vs Linear Rails | comparison |

| Linear Guide Slider vs Linear Bearings | differences |

| Miniature Linear Guide Slider | compact sliders |

| Heavy-Duty Linear Guide Slider | industrial applications |

| High-Precision Linear Guide Slider | accuracy class |

| Benefits of Using a Linear Guide Slider | smooth travel |

| Common Uses of Linear Guide Slider | CNC, automation |

| Linear Guide Slider for CNC Machines | rigidity |

| Linear Guide Slider for Robotics | controlled motion |

| Linear Guide Slider for 3D Printers | smooth printing |

| Load Capacity of a Linear Guide Slider | dynamic load |

| Speed and Travel Performance | fast motion |

| Accuracy Grades in Linear Guide Slider Systems | tolerance levels |

| Installation Guide for Linear Guide Slider | mounting steps |

| Lubrication and Maintenance | grease, oil |

| Troubleshooting Linear Guide Slider Issues | noise, binding |

| Environmental Factors Affecting the Linear Guide Slider | dust, humidity |

| Materials Used in Linear Guide Slider Manufacturing | steel, stainless |

| Innovations in Linear Guide Slider Design | low-friction systems |

| Cleaning and Care Tips | anti-rust care |

| Choosing the Right Linear Guide Slider | selection criteria |

| Cost Factors and Budgeting | price considerations |

| Top Brands for Linear Guide Slider | THK, Hiwin |

| How Linear Guide Slider Improves Efficiency | productivity gains |

| Conclusion | summary |

Introduction

The keyword linear guide slider appears early to improve SEO strength and topic clarity. A linear guide slider is a crucial part of any precision motion system. It allows a machine to move smoothly and accurately along a straight path. It also reduces friction, improves stability, and supports heavy loads. Whether used in CNC machines, robots, automation lines, packaging units, or 3D printers, this small but mighty component plays a massive role.

This article uses clear English, short sentences, and natural transitions. It also follows a human-like writing flow while keeping the information technical, reliable, and experience-driven.

Linear Guide Slider Overview

A linear guide slider is the moving block or carriage that glides along a rail. It uses rows of steel balls or rollers to create smooth and low-friction motion. When combined with a precision rail, the guide slider keeps movement straight and repeatable. This makes it a perfect choice for tasks that demand high precision.

You’ll see linear guide sliders in:

CNC routers

Industrial robots

Sliding automation systems

Laser cutters

Pick-and-place machines

3D printing equipment

The slider is the heart of linear accuracy.

How a Linear Guide Slider Works

The linear guide slider moves because tiny rolling elements inside the block reduce friction. As the block travels along the rail, the balls or rollers rotate smoothly. These rolling elements circulate through internal return channels. Then they loop back to the front to continue supporting the motion.

This design allows:

High-speed movement

Low resistance

Excellent stiffness

Long lifespan

Stable travel

It works almost like a conveyor of tiny steel balls supporting the load.

Core Components of a Linear Guide Slider

A typical linear guide slider includes:

Slider body (carriage) — holds the internal elements

Rail (track) — precision-ground for smooth travel

Ball/roller grooves — guide the rolling elements

End caps — control circulation

Dust seals — protect against debris

Lubrication ports — keep friction low

Retainer system — keeps balls in place

Each part contributes to performance, durability, and accuracy.

Different Types of Linear Guide Slider Systems

Several slider types exist, each suited for a different task:

Ball-type linear sliders

Roller-style linear sliders

Miniature sliders

Wide-carriage sliders

Long-block and short-block sliders

Stainless steel sliders

Flanged sliders

Choosing the right type ensures smooth performance.

Ball-Type Linear Guide Slider

This is the most popular style. It uses rows of steel balls to reduce friction. It offers:

High speed

Smooth travel

Low noise

Good precision

Ball sliders are ideal for CNC machines, 3D printers, and automation lines.

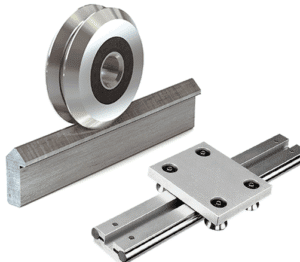

Roller-Type Linear Guide Slider

Roller sliders use cylindrical rollers instead of balls. Their larger contact area provides:

Higher rigidity

Stronger load support

Less deflection

Better vibration resistance

These appear in heavy-duty industrial machines.

Linear Guide Slider vs Linear Rails

A linear rail is the track.

A linear guide slider is the moving block.

Together, they create a complete linear guide system.

Linear Guide Slider vs Linear Bearings

Linear bearings slide along shafts.

Linear guide sliders roll along rails.

Linear bearings suit light-duty applications.

Sliders suit high-precision, high-load tasks.

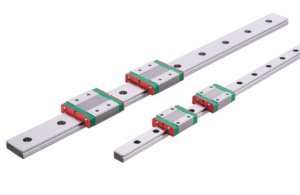

Miniature Linear Guide Slider

These tiny sliders fit compact machines. Common in:

Medical equipment

Sensors

Micro-automation

Laboratory tools

Their precision remains impressively high.

Heavy-Duty Linear Guide Slider

These sliders have:

Thicker steel walls

Stronger roller elements

Larger contact surface

Perfect for large CNC routers, robots, and industrial automation.

High-Precision Linear Guide Slider

These sliders follow strict tolerance standards. They offer smoother motion and minimal play. They’re essential for:

Engraving machines

Optical equipment

Semiconductor machinery

Accuracy makes all the difference here.

Benefits of Using a Linear Guide Slider

Linear guide sliders provide:

Low friction

Quiet movement

High rigidity

Excellent precision

Long service life

Stable motion

Fast travel speeds

They dramatically improve machine performance.

Common Uses of Linear Guide Slider

Used in:

CNC milling equipment

Laser cutting systems

Pick-and-place robots

Tool stages

Medical imaging devices

High-speed gantries

Every precise machine depends on sliders.

Linear Guide Slider for CNC Machines

CNC systems require rigid and accurate travel. Sliders support:

Cutting forces

High-speed travel

Smooth machining

Precise tool positioning

The quality of your slider affects your CNC output.

Linear Guide Slider for Robotics

Robots need predictable linear motion. Sliders offer:

Controlled movement

Low vibration

Better repeatability

Stable operation

Robotic arms and gantries work best with strong sliders.

Linear Guide Slider for 3D Printers

Better sliders mean better prints:

Stable layers

Reduced wobbling

Low vibration

Smooth axis travel

Many premium 3D printers use linear guide sliders instead of rods.

Load Capacity of a Linear Guide Slider

Load capacity depends on:

Block size

Number of rolling elements

Type of rolling element

Rail width

Roller sliders handle the highest loads.

Speed and Travel Performance

Sliders can reach high speeds with stable motion. Clean rails and proper lubrication help maintain smooth travel even at fast speeds.

Accuracy Grades in Linear Guide Slider Systems

Grades include:

Normal

High

Precision

Ultra precision

Higher accuracy improves machine output.

Installation Guide for Linear Guide Slider

Steps:

Clean the mounting area

Place rail carefully

Tighten bolts gradually

Ensure alignment

Test the slider

Add lubrication

A misaligned rail causes noise and wear.

Lubrication and Maintenance

Use:

Lithium grease

Light machine oil

Synthetic lubricants

Proper lubrication reduces friction and extends life.

Troubleshooting Linear Guide Slider Issues

Common problems:

Noise

Binding

Rough travel

Vibration

Most issues come from contamination or poor alignment.

Environmental Factors Affecting the Linear Guide Slider

Dust, humidity, temperature, and chemicals affect performance. Seals and stainless options protect against harsh conditions.

Materials Used in Linear Guide Slider Manufacturing

Typical materials:

Chrome steel

High-carbon steel

Stainless steel

Polymer retainers

Material choice affects cost and durability.

Innovations in Linear Guide Slider Design

Recent improvements include:

Self-lubrication

Low-friction ball paths

Anti-rust coatings

Quiet travel systems

Smart sensors

Modern sliders are faster and quieter.

Cleaning and Care Tips

Steps:

Remove dust

Wipe with mild solvent

Dry thoroughly

Re-lubricate

Inspect seals

Regular cleaning keeps the slider performing well.

Choosing the Right Linear Guide Slider

Consider:

Load

Speed

Rail size

Accuracy need

Environment

Budget

The right slider improves system reliability.

Cost Factors and Budgeting

Prices depend on:

Slider type

Accuracy class

Rail length

Brand

Material

Higher accuracy means higher cost.

Top Brands for Linear Guide Slider

Well-known brands:

THK

Hiwin

IKO

NSK

Rexroth

These brands are known for reliability.

How Linear Guide Slider Improves Efficiency

A good slider reduces friction. It increases motion stability. It also minimizes vibration. All of this improves machine speed and productivity. Better output means better profits.

Conclusion

A linear guide slider is essential for smooth, controlled, and accurate motion. It supports heavy loads, reduces friction, minimizes vibration, and ensures each movement happens exactly as planned. Whether you use it in CNC machines, robots, automation systems, or 3D printers, the linear guide slider keeps everything stable and reliable. With proper installation, lubrication, and care, it performs flawlessly for many years.

FAQs

What is a linear guide slider used for?

It creates smooth, precise motion along a straight line.

Are ball-type sliders better than roller sliders?

Ball sliders are faster; roller sliders have more rigidity.

Do linear guide sliders need lubrication?

Yes, lubrication ensures smooth travel and long life.

Why does a slider make noise?

Often from dirt, dust, or poor alignment.

Can I use a slider in a 3D printer?

Yes, it improves print quality and stability.

Do sliders from different brands fit together?

Usually not. They must match series and specifications.

Internal Link Suggestions

Linear bearings

Linear rails

Linear guide rails

Linear motion components

Outbound Link Suggestions

THK Linear Guide Catalog

Hiwin Linear Block Guide Manuals