Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Linear Track Overview | linear motion track |

| What Is a Linear Track? | linear guide track |

| How a Linear Track Works | rail and carriage |

| Different Types of Linear Track Designs | track variations |

| Core Components of a Linear Track System | track, rail, blocks |

| Benefits of Using a Linear Track System | precision movement |

| Linear Track for Heavy-Duty Applications | industrial track |

| Miniature Linear Track Options | small linear systems |

| Choosing the Right Linear Track Size | track dimensions |

| Linear Track Materials and Coatings | steel, surface finish |

| Linear Track Load Capacity Factors | ratings |

| Linear Track Accuracy and Repeatability | precision |

| Mounting a Linear Track the Right Way | installation |

| Linear Track Alignment Techniques | straightness |

| Lubrication Requirements for Linear Tracks | maintenance |

| Common Mistakes When Using Linear Tracks | errors |

| How to Extend Linear Track Lifespan | durability |

| Linear Track vs Linear Rail Systems | comparison |

| Linear Track in CNC Machines | machining motion |

| Linear Track in Robotics and Automation | robotics track |

| Linear Track for 3D Printers and DIY Builders | maker projects |

| Noise and Vibration Control in Linear Track Systems | damping |

| Thermal Effects on Linear Track Performance | heat expansion |

| Upgrading an Old Machine with Linear Track | retrofitting |

| Cost Considerations for Linear Track Systems | pricing |

| New Innovations in Linear Track Engineering | next-gen design |

| Real-World Examples of Linear Track Applications | industry |

| Maintenance Checklist for Linear Track Systems | inspection |

| Conclusion | summary |

Linear Track

Introduction

The keyword linear track sits early in this introduction to improve SEO clarity. When engineers design machines for precise linear motion, they often turn to a linear track. It delivers straight, smooth travel with minimal friction. Whether you build CNC routers, robotic arms, 3D printers, packaging lines, or industrial automation tools, the linear track becomes a major part of machine stability and accuracy.

Although a linear track might look simple—a rail combined with a moving block—its engineering is more complex than most people think. Small design choices can dramatically change how it performs. This detailed guide breaks everything down using clear English, short sentences, and helpful transitions.

Linear Track Overview

A linear track offers low-friction movement along a straight path. It uses rolling elements inside a carriage or slider. The track itself is usually hardened metal. Together, they create a rigid motion platform used across many industries.

What Is a Linear Track?

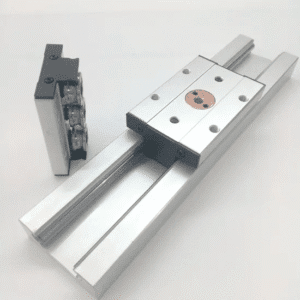

A linear track is a mechanical system that guides objects along a straight path using rails and sliding or rolling components. It works as the backbone of linear motion. You often see it in CNC machines, automation lines, and robotics where motion accuracy matters.

How a Linear Track Works

It works by replacing sliding friction with rolling friction. Balls or rollers move inside a carriage while the carriage moves along the track. Because everything is hardened and polished, friction stays low and movement stays smooth.

Different Types of Linear Track Designs

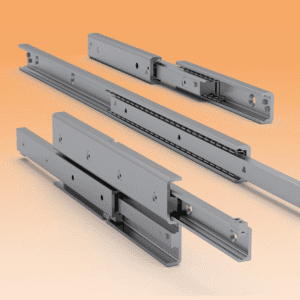

Common types include:

Ball-bearing linear track

Roller-bearing linear track

Miniature linear track

Wide-body linear track

Self-lubricating track

Extended travel track

Each design offers different strength, accuracy, and motion advantages.

Core Components of a Linear Track System

A typical system includes:

Track/Rail

Carriage/Slider

Balls or rollers

Seals and wipers

End caps

Lubrication ports

These parts work together to support load and motion.

Benefits of Using a Linear Track System

A linear track offers:

Low friction

Long lifespan

High load capacity

Excellent straight-line accuracy

Smooth movement

Low noise

These benefits make linear tracks ideal for demanding machines.

Linear Track for Heavy-Duty Applications

Some machines require high rigidity. Heavy-duty linear track systems use:

Thicker rails

Larger roller blocks

Higher preload

Stronger mounting surfaces

They support heavy loads without flexing.

Miniature Linear Track Options

Mini linear tracks are compact and lightweight. They are perfect for:

Medical instruments

Lab automation

Precision electronics equipment

Small robotic systems

Their smooth micro-movement is useful in delicate machines.

Choosing the Right Linear Track Size

Consider:

Load weight

Load direction

Track width

Track height

Travel length

Speed

Shock and vibration

A proper size prevents premature wear.

Linear Track Materials and Coatings

Most tracks use:

High-carbon steel

Stainless steel

Special alloy steel

Coatings like hard chrome or black oxide increase corrosion resistance.

Linear Track Load Capacity Factors

Load capacity depends on:

Ball/roller size

Rail hardness

Carriage length

Number of carriages

Preload level

Heavy loads require roller-based tracks.

Linear Track Accuracy and Repeatability

Accuracy depends on:

Rail straightness

Carriage preload

Quality of ground surfaces

Flatness of mounting surface

Even tiny errors in the rail impact machine precision.

Mounting a Linear Track the Right Way

Mounting tips:

Clean the surface

Remove dust or burrs

Tighten bolts in sequence

Move the carriage along the track to test smoothness

Avoid forcing alignment

Good mounting improves system lifespan.

Linear Track Alignment Techniques

Use:

Alignment pins

Dowel holes

Dial indicators

Straightedges

A perfectly aligned linear track reduces friction.

Lubrication Requirements for Linear Tracks

Lubrication is essential. It reduces internal wear, removes heat, and prevents corrosion. Most systems use grease, but high-speed machines may prefer oil.

Common Mistakes When Using Linear Tracks

Avoid:

Mounting on uneven surfaces

Overloading

Using incorrect lubrication

Running without seals

Over-tightening bolts

These mistakes reduce accuracy and lifespan.

How to Extend Linear Track Lifespan

To extend life:

Lubricate frequently

Clean rails regularly

Keep preload appropriate

Protect the track from dust

Maintain straight alignment

Consistent maintenance improves reliability.

Linear Track vs Linear Rail Systems

A linear track is similar to a linear rail. However, “linear track” often refers to systems used in lighter or more flexible applications. Linear rails usually describe heavier-duty motion systems.

Linear Track in CNC Machines

CNC machines rely on stiff linear tracks for:

Fast travel

High precision

Heavy-tool support

Stable operations

Without a strong track, a CNC loses accuracy.

Linear Track in Robotics and Automation

Robots need:

Smooth motion

Low vibration

High repeatability

Linear tracks help robotic arms and gantry systems move with confidence.

Linear Track for 3D Printers and DIY Builders

Many makers use linear tracks to upgrade:

3D printer axes

Laser engravers

DIY CNC routers

Tracks provide cleaner, quieter motion.

Noise and Vibration Control in Linear Track Systems

To minimize noise:

Use sealed carriages

Choose roller types

Improve rail support

Add dual rails

A quiet track boosts machine stability.

Thermal Effects on Linear Track Performance

Temperature changes affect steel. Heat expands the rail and shifts alignment. Machines operating near heat sources need temperature-stable materials.

Upgrading an Old Machine with Linear Track

Upgrades offer:

Better smoothness

Higher accuracy

Longer lifespan

Lower noise

It’s one of the best improvements for aging equipment.

Cost Considerations for Linear Track Systems

Price varies by:

Rail length

Material

Carriage type

Brand

Precision rating

Although expensive, high-quality linear tracks save money long-term.

New Innovations in Linear Track Engineering

Modern developments include:

Self-lubricating tracks

Coated steel for corrosion resistance

Lightweight composite tracks

Smart sensors for wear detection

Innovation continues to reshape linear motion engineering.

Real-World Examples of Linear Track Applications

You’ll see linear tracks in:

Industrial robots

CNC routers

Packaging machines

Medical scanners

Laboratory automation

Aerospace inspection tools

They handle precision tasks across many industries.

Maintenance Checklist for Linear Track Systems

Use this quick list:

Clean rails weekly

Lubricate monthly

Check preload yearly

Inspect for dust and debris

Examine seals for wear

Verify mounting bolts

A consistent routine keeps the track performing like new.

Conclusion

A linear track plays a major role in creating accurate and stable linear motion. Whether used in CNC machines, robotics, automation lines, or 3D printers, its precision and smoothness help increase performance. With the right size, material, lubrication, and installation technique, a linear track system delivers reliable, long-lasting motion that improves machine productivity.

FAQs

What is a linear track used for?

It guides movement along a straight path with low friction.

Are linear tracks easy to install?

Yes, but proper alignment is important to prevent binding.

Do linear tracks need lubrication?

Yes. Lubrication reduces wear and improves motion smoothness.

Can linear tracks handle heavy loads?

Yes, especially roller-based heavy-duty designs.

Where are linear tracks most common?

CNC, robotics, packaging, 3D printing, and medical equipment.

How long can a linear track last?

With proper care, many last years or even decades.

Internal Link Suggestions

Linear guide rails

Linear bearings and guides

Linear guide slider

Outbound Link Suggestions

HIWIN linear motion catalog

NSK linear guide engineering manual