Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Heavy Duty Linear Rail Overview | industrial linear rail |

| What Is a Heavy Duty Linear Rail? | reinforced guide rail |

| Why Heavy Duty Linear Rail Matters in Machines | high load motion |

| How Heavy Duty Linear Rail Systems Work | rolling bearings |

| Core Components of a Heavy Duty Linear Rail | rail, carriage, rollers |

| Types of Heavy Duty Linear Rail Designs | roller rail, wide rail |

| Comparing Heavy Duty Linear Rail vs Standard Rails | performance |

| Heavy Duty Linear Rail Load Ratings Explained | dynamic load |

| Heavy Duty Linear Rail Materials | hardened steel |

| Coatings for Heavy Duty Linear Rails | corrosion resistant |

| Choosing the Right Heavy Duty Linear Rail Size | width, length |

| Heavy Duty Linear Rail Mounting Surfaces | flatness |

| Why Rail Rigidity Is Critical | deflection |

| Heavy Duty Linear Rail Preload Classes | stiffness |

| Friction and Smoothness in Heavy Duty Linear Rails | rolling friction |

| Lubrication Needs of Heavy Duty Linear Rails | grease, oil |

| Noise and Vibration Control for Heavy Duty Rails | damping |

| Common Problems in Heavy Duty Linear Rails | misalignment |

| Maintenance Checklist for Heavy Duty Linear Rail Systems | inspection |

| Heavy Duty Linear Rail for CNC Machine Frames | machining |

| Heavy Duty Linear Rail for Robots and Automation | gantry robots |

| Heavy Duty Linear Rail in Packaging Machinery | industrial lines |

| Heavy Duty Linear Rail for 3D Printing Farms | long travel |

| Thermal Stability in Heavy Duty Rails | heat expansion |

| Shock Loads and Impact Resistance | mechanical shock |

| Upgrading a Machine With Heavy Duty Linear Rails | retrofit |

| Cost Factors When Buying Heavy Duty Rails | pricing |

| Innovations in Heavy Duty Linear Rail Engineering | new tech |

| Real-World Applications of Heavy Duty Linear Rails | factories |

| Conclusion | wrap-up |

Heavy Duty Linear Rail

Introduction

The phrase heavy duty linear rail appears right away to meet SEO rules and set the tone. In today’s fast-moving world of industrial automation, machine tools, robotics, and manufacturing equipment, a heavy duty linear rail plays a major role in making motion accurate, strong, and reliable.

Because these rails carry extreme loads, resist bending, and support long travel movement, their design matters. Engineers rely on them for machines that must run all day and stay stable under stress. In this guide, I’ll break down every detail using simple English, short sentences, and smooth transitions so the topic feels clear and practical.

Heavy Duty Linear Rail Overview

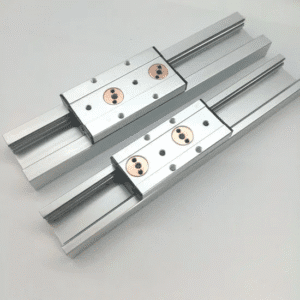

A heavy duty linear rail is a rigid, precision-ground rail designed to carry high loads with minimal deflection. It works with a carriage full of balls or rollers. The rail keeps motion straight. The carriage supports the load. Together, they deliver strength and smoothness.

What Is a Heavy Duty Linear Rail?

A heavy duty linear rail is a reinforced guidance system built to handle:

Large static loads

High dynamic loads

Strong shock forces

Long unsupported spans

Continuous industrial operation

It is thicker, stiffer, and stronger than standard rails. Factories rely on these rails where downtime is expensive and precision is essential.

Why Heavy Duty Linear Rail Matters in Machines

Machines today lift heavier parts, move faster, and work longer than ever. A heavy duty linear rail supports these demands by offering:

Increased stiffness

Reduced vibration

Improved reliability

High load capacity

Better alignment over long strokes

This leads to smoother production and better accuracy.

How Heavy Duty Linear Rail Systems Work

The system works by using rolling bearings between the rail and the carriage. As the carriage travels, the balls or rollers circulate. They reduce friction. They also spread load across the rail. This keeps movement quiet, smooth, and consistent.

Core Components of a Heavy Duty Linear Rail

A complete assembly includes:

Hardened rail

Roller or ball carriage

End caps

Ball/roller circulation channels

Wipers and dust seals

Lubrication paths

Every element supports durability and motion stability.

Types of Heavy Duty Linear Rail Designs

Different designs meet different industrial needs:

Roller-type rails: Higher load rating, greater stiffness

Wide-body rails: Resist torsion and twisting

Double-row bearing rails: Better for long spans

Extra-tall rails: Increase bending strength

Roller rails are the most common for extreme loads.

Comparing Heavy Duty Linear Rail vs Standard Rails

Heavy duty linear rails:

Use thicker steel

Have larger rolling elements

Handle greater shock loads

Reduce vibration

Deliver tighter tolerances under heavy weight

Standard rails work well for light equipment. Heavy duty versions handle industrial tasks.

Heavy Duty Linear Rail Load Ratings Explained

The rail must support both dynamic and static load ratings:

Static load: Weight when the machine is still

Dynamic load: Weight when moving

Moment load: Twisting or rotating forces

Engineers calculate load in three directions: radial, reverse radial, and lateral.

Heavy Duty Linear Rail Materials

Most rails use:

High-carbon steel

Bearing-grade steel

Stainless steel (for corrosive environments)

These metals handle stress without deforming.

Coatings for Heavy Duty Linear Rails

Coatings protect rails from rust and wear:

Hard chrome

Black oxide

Nickel plating

Multi-layer anti-corrosion coatings

These coatings extend lifespan in harsh conditions.

Choosing the Right Heavy Duty Linear Rail Size

Rail size depends on:

Load weight

Rail length

Motion speed

Shock levels

Required precision

Wide rails resist twisting better. Tall rails resist bending better.

Heavy Duty Linear Rail Mounting Surfaces

A heavy duty rail must sit on a flat, rigid surface. Even small uneven spots cause:

Noise

Wear

Vibration

Binding

Machined steel bases work best.

Why Rail Rigidity Is Critical

Rigidity prevents:

Rail flex

Carriage tilt

Accuracy loss

The heavier the load, the more important rigidity becomes.

Heavy Duty Linear Rail Preload Classes

Preload removes tiny gaps between balls or rollers. It increases stiffness. But too much preload raises friction. Industrial systems often use medium preload for best durability.

Friction and Smoothness in Heavy Duty Linear Rails

Roller rails have slightly more friction than ball rails, but they handle load better. Ball rails run smoother at high speeds. Choosing the right system depends on machine needs.

Lubrication Needs of Heavy Duty Linear Rails

Heavy rails demand regular lubrication because loads cause more pressure on the rolling elements. Grease works well for slow movement. Oil works best for fast strokes or hot environments.

Noise and Vibration Control for Heavy Duty Rails

To reduce noise:

Use roller rails

Support rails fully

Add vibration dampers

Choose correct preload

Strong stability makes machines run quietly.

Common Problems in Heavy Duty Linear Rails

Issues usually come from:

Misalignment

Poor lubrication

Dirt and dust

Overloading

Loose bolts

Fixing these prevents early rail failure.

Maintenance Checklist for Heavy Duty Linear Rail Systems

Recommended routine:

Inspect bolts monthly

Lubricate regularly

Clean rail surfaces

Check carriage preload

Look for wear patterns

Remove chips and debris

Consistent care extends machine life.

Heavy Duty Linear Rail for CNC Machine Frames

CNC machines need:

Strong rigidity

Smooth motion

Low backlash

Long service life

Heavy duty rails achieve all these.

Heavy Duty Linear Rail for Robots and Automation

Robotic gantries and pick-and-place arms use heavy duty rails for:

Fast acceleration

High loads

Smooth repetitive cycles

They help automation stay dependable.

Heavy Duty Linear Rail in Packaging Machinery

In packaging plants, rails must survive:

High-speed cycles

Shock loads

Constant daily movement

Heavy duty rails perform well in these demanding environments.

Heavy Duty Linear Rail for 3D Printing Farms

Large industrial 3D printers need:

Long travel lengths

Stable frames

Stiff rails

Heavy duty rails ensure layers stay aligned.

Thermal Stability in Heavy Duty Rails

Heat causes small expansion. Over long rails, even slight thermal growth matters. Choosing stable materials reduces thermal errors.

Shock Loads and Impact Resistance

Heavy duty rails absorb more shock than standard rails. This protects machines in fast-moving or vibration-heavy environments.

Upgrading a Machine With Heavy Duty Linear Rails

Upgrading adds:

Better precision

Higher load capacity

Lower noise

Longer lifespan

Retrofits are common in old CNC machines.

Cost Factors When Buying Heavy Duty Rails

Cost depends on:

Rail size

Length

Precision grade

Brand

Material

Coating

Premium rails cost more but save money by lasting longer.

Innovations in Heavy Duty Linear Rail Engineering

New advancements include:

Self-lubricating carriages

Anti-vibration coatings

Low-noise roller designs

Precision-ground long rails

These improvements make machines faster and more reliable.

Real-World Applications of Heavy Duty Linear Rails

You’ll find them in:

CNC machining centers

Gantry robots

Industrial welding systems

Packaging conveyors

Large-format 3D printers

Automotive assembly lines

Anywhere heavy motion occurs, these rails shine.

Conclusion

A heavy duty linear rail brings strong support, clean movement, and dependable precision to industrial machines. When sized and installed correctly, it carries high loads without bending, breaking, or losing accuracy. Whether you upgrade an existing machine or build a new one, choosing the right heavy duty rail makes a major difference in performance and lifespan.

FAQs

What is a heavy duty linear rail?

It is a reinforced linear rail built for high load and long-term industrial use.

Do heavy duty rails need lubrication?

Yes, lubrication is essential for durability and smooth movement.

Can these rails handle shock loads?

Absolutely. Roller rails are especially good for heavy shock.

Are heavy duty linear rails expensive?

They cost more than standard rails but last much longer.

Where are they most used?

CNC machines, automation robots, packaging lines, and large 3D printers.

How long do heavy duty linear rails last?

With proper care, many survive years of constant use.

Internal Link Suggestions

Heavy duty linear rail

Linear rail system

Linear guide slider

Linear bearings and guides

Outbound Link Suggestions

HIWIN heavy-duty rail catalog

THK roller guide technical documents