Introduction

In modern automation, robotics, and precision manufacturing, achieving smooth, accurate linear motion is essential. A critical component that enables this motion is the slide rail linear system.

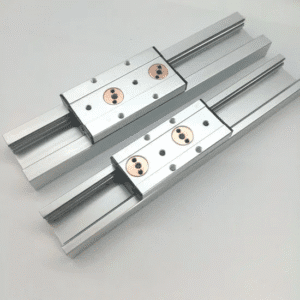

A slide rail linear system consists of a rail and a sliding carriage (or block) that moves along the rail to provide precise, low-friction, and repeatable linear movement. These systems are widely used in CNC machines, 3D printers, industrial robots, packaging machinery, medical equipment, and automated assembly lines.

This article provides a comprehensive overview of slide rail linear systems, covering structure, working principles, types, materials, advantages, applications, selection criteria, and maintenance best practices.

What Is a Slide Rail Linear System?

A slide rail linear system is a mechanical assembly that guides motion along a straight path while supporting loads. Unlike traditional sliding mechanisms, modern systems often incorporate recirculating balls or rollers inside the carriage to reduce friction and increase precision.

Key functions include:

Guiding linear motion accurately

Supporting radial, axial, and moment loads

Reducing friction and wear

Providing smooth and repeatable movement

Slide rail linear systems are widely used where accuracy, stability, and smoothness are critical.

Core Components of a Slide Rail Linear System

1. Linear Rail

Precision-machined track providing a stable path for the carriage

Usually made from hardened steel, stainless steel, or aluminum

Provides rigidity and supports applied loads

2. Sliding Carriage (Slider/Block)

Moves along the rail while carrying the load

Houses recirculating balls or rollers to reduce friction

Ensures smooth motion and alignment

3. Rolling Elements

Reduce friction between the rail and carriage

Steel balls for high precision or cylindrical rollers for higher load capacity

Circulate continuously inside the carriage

4. Seals, Wipers, and Lubrication Ports

Protect the internal mechanisms from dust and debris

Ensure proper lubrication for long-term operation

Working Principle of Slide Rail Linear Systems

Slide rail linear systems operate on rolling contact:

The carriage slides along the fixed rail under load.

Rolling elements inside the carriage reduce friction and wear.

The system supports radial, axial, and moment loads simultaneously.

Motion remains smooth, precise, and repeatable, even under heavy loads or high speed.

This principle provides high accuracy, energy efficiency, and long service life, making these systems ideal for industrial automation and precision machinery.

Types of Slide Rail Linear Systems

1. Ball-Type Slide Rail Linear Systems

Use recirculating steel balls inside the carriage

High precision and smooth operation

Commonly used in CNC machines, 3D printers, and light-to-medium automation equipment

2. Roller-Type Slide Rail Linear Systems

Use cylindrical or needle rollers

Higher rigidity and load capacity

Suitable for heavy machinery, industrial robots, and large-scale automation

3. Profile Slide Rail Linear Systems

Compact rail with integrated carriage

Supports multi-directional loads and high stiffness

Common in robotics, CNC machining, and automated assembly lines

4. Miniature Slide Rail Linear Systems

Small and lightweight for tight spaces

Suitable for medical devices, electronics assembly, and laboratory automation

5. Aluminum Slide Rail Linear Systems

Lightweight and corrosion-resistant

Ideal for portable machines, robots, and 3D printers

6. Round Shaft Slide Rail Linear Systems

Cylindrical shafts with linear bushings

Cost-effective for light-load and non-critical applications

Advantages of Slide Rail Linear Systems

High Precision – Maintains tight tolerances and repeatability

Low Friction – Reduces wear and energy consumption

High Load Capacity – Supports radial, axial, and moment loads efficiently

Durability – Long service life due to optimized load distribution

Rigidity – High stiffness reduces deflection and vibration

Versatility – Suitable for CNC machines, 3D printers, robotics, packaging, and automation

Ease of Installation & Maintenance – Pre-drilled rails and lubrication ports simplify setup

Applications of Slide Rail Linear Systems

Slide rail linear systems are widely used wherever precision and smooth motion are required:

CNC machining centers – Milling, drilling, and cutting

3D printers – Smooth movement of print heads and build platforms

Industrial robots – Linear actuators for assembly, pick-and-place, and welding

Packaging machinery – Filling, labeling, sorting, and material handling

Medical and laboratory automation – Imaging, diagnostics, and automated testing

Semiconductor manufacturing – High-precision wafer handling stages

Heavy machinery – Presses, conveyors, and large automation systems

Materials Used in Slide Rail Linear Systems

Hardened Steel – High strength, wear resistance; standard industrial use

Stainless Steel – Corrosion-resistant for harsh or cleanroom environments

Aluminum Alloy – Lightweight and corrosion-resistant for portable applications

Special Coatings – Low-friction, anti-wear, or corrosion-resistant coatings for improved performance

Material selection depends on load, speed, precision, and environmental conditions.

How to Choose the Right Slide Rail Linear System

Load Requirements – Static, dynamic, and moment loads

Precision Level – Required accuracy and repeatability

Travel Distance – Rail length must match application needs

Environmental Conditions – Dust, moisture, temperature, and chemical exposure

Speed & Acceleration – System must handle operational dynamics

Maintenance Requirements – Self-lubricating or easily lubricated systems

Space Constraints – Miniature or compact rails for tight installations

Installation Best Practices

Mount rails on flat, rigid surfaces to prevent bending or deflection

Align rails precisely to prevent binding and uneven wear

Fasten rails using correct torque specifications

Apply recommended lubrication before initial operation

Avoid overloading or misalignment during installation

Proper installation ensures optimal performance, precision, and longevity.

Maintenance Guidelines

Keep rails and carriages free from dust, debris, and contaminants

Re-lubricate rolling elements regularly according to operational conditions

Inspect for wear, misalignment, or corrosion

Replace worn or damaged components promptly

Routine maintenance ensures smooth motion, precision, and long service life.

Future Trends in Slide Rail Linear Systems

Smart Slide Rails – Embedded sensors for monitoring position, load, and temperature

IoT Integration – Real-time monitoring for predictive maintenance

Low-Friction Coatings – Enhance efficiency and reduce wear

Lightweight Hybrid Materials – Steel-aluminum combinations for reduced weight

Maintenance-Free Designs – Self-lubricating or sealed systems for minimal downtime

These trends are driving greater precision, efficiency, and reliability in modern automation and manufacturing.

Frequently Asked Questions (FAQs)

1. What is a slide rail linear system used for?

It provides precise, smooth, and low-friction linear motion in CNC machines, robots, and industrial automation.

2. What types of slide rail linear systems exist?

Ball-type, roller-type, profile rail, miniature, aluminum, and round shaft systems.

3. Can slide rail linear systems handle heavy loads?

Yes, particularly roller-type and high-rigidity profile systems.

4. Do slide rail linear systems require lubrication?

Yes, proper lubrication reduces wear and ensures smooth operation.

5. What materials are used for slide rail linear systems?

Hardened steel, stainless steel, aluminum alloys, and coated materials based on load, environment, and precision needs.

6. How do slide rail linear systems differ from linear shafts?

Slide rails provide higher rigidity, multi-directional load support, and superior precision compared to round shafts with bushings.

Conclusion

A slide rail linear system is a critical component in modern machinery, robotics, and industrial automation, delivering smooth, precise, and stable linear motion. Its combination of high load capacity, low friction, and rigidity makes it essential for applications such as CNC machining, 3D printing, industrial robots, packaging machinery, and medical devices.

Choosing the right system, material, and configuration, along with proper installation and maintenance, ensures long-lasting performance, precision, and reliability. With advances in smart sensors, hybrid materials, and maintenance-free designs, slide rail linear systems will continue to play a pivotal role in precision engineering and automation.