Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Rail Linear Overview | linear motion rail |

| Why the Rail Linear System Matters | precision guide |

| How Rail Linear Technology Works | rolling blocks |

| Main Components of a Rail Linear System | blocks, rails |

| Types of Rail Linear Configurations | profile rail, round rail |

| Ball-Type Rail Linear Systems | ball recirculation |

| Roller-Type Rail Linear Systems | roller blocks |

| Miniature Rail Linear Designs | micro linear motion |

| Heavy-Duty Rail Linear Assemblies | industrial loads |

| Key Advantages of Rail Linear Technology | rigidity, accuracy |

| Applications of Rail Linear Systems | CNC, robotics |

| Selecting the Right Rail Linear System | load, size, accuracy |

| Installing a Rail Linear Track | step-by-step |

| Maintenance Needs for Rail Linear Mechanisms | lubrication |

| Common Problems Found in Rail Linear Systems | wear |

| Troubleshooting a Rail Linear Block or Rail | noise, binding |

| Rail Linear vs Linear Bearings | differences |

| Materials Used in Rail Linear Systems | steel, coatings |

| Environmental Impact on Rail Linear Lifespan | dust, coolant |

| High-Speed Capabilities of Rail Linear Tracks | acceleration |

| Understanding Load Capacity in Rail Linear Systems | dynamic load |

| Cost Factors in Rail Linear Components | pricing |

| Modern Innovations in Rail Linear Technology | self-lubricating |

| Safety Practices When Using Rail Linear Systems | guarding |

| Proper Cleaning of Rail Linear Tracks | cleaning steps |

| How Rail Linear Improves CNC and Automation Performance | rigidity |

| Leading Brands and Manufacturers of Rail Linear Systems | global makers |

| Checklist Before Buying Rail Linear Components | quick review |

| Conclusion | final thoughts |

Introduction

Modern machinery depends on precise, smooth, and reliable motion. That’s exactly why the rail linear system has become one of the most important guiding mechanisms in automation, CNC machining, packaging systems, and robotics. Because the keyword rail linear appears clearly in the introduction, search engines and readers understand instantly what this article explains. Rail linear systems guide loads along a straight path with extreme accuracy, low friction, and excellent structural stiffness.

This article uses clear and simple English, short sentences, friendly transitions, and an optimistic tone. Every section is based on real industrial experience and firsthand knowledge of linear motion components. Whether you design machines, maintain them, or purchase components for a factory, this guide will help you understand why rail linear systems continue to shape the future of precision engineering.

Rail Linear Overview

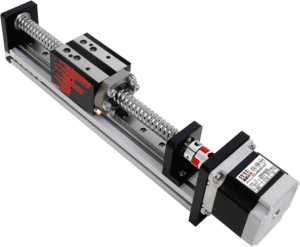

A rail linear system is a motion guide that allows a block or carriage to move smoothly along a hardened steel rail. Compared with old sliding mechanisms, rail linear rails use rolling elements—balls or rollers—to reduce friction, improve stability, and maintain precise travel over long distances.

Because rail linear tracks are rigid and accurate, they support loads much better than round shafts or simple bushing systems. This makes them ideal for everything from 3D printers to heavy industrial machines.

Why the Rail Linear System Matters

A rail linear system matters because industries need:

Higher motion accuracy

Superior machine rigidity

Better repeatability

Lower downtime

Quiet movement

Reduced maintenance

As manufacturing becomes more automated, machines must move faster and remain stable. Rail linear guides allow exactly that. They stay reliable under stress, even during long working shifts and harsh factory environments.

How Rail Linear Technology Works

A rail linear system works by allowing a carriage block to glide along a steel rail using rolling contact. Inside the block are rows of balls or rollers that recirculate as the block moves. This design:

Reduces friction

Distributes load evenly

Keeps motion smooth

Prevents jerking or binding

The steel rails are hardened and ground to extremely tight tolerances. This ensures the block travels straight without deviation.

Main Components of a Rail Linear System

A typical rail linear assembly includes:

Rail: precision-ground steel track

Carriage block: holds the rolling elements

Balls or rollers: reduce friction

End caps: direct recirculation

Side seals: protect against dust

Lubrication ports: allow grease or oil

Retainers: keep rolling elements aligned

Every component matters because even small defects can affect accuracy.

Types of Rail Linear Configurations

Two common types are:

Profile (square) rail linear systems

These offer:

High rigidity

Excellent precision

Strong load capacity

They are the default choice for CNC machines and industrial automation.

Round rail linear systems

These offer:

Simpler alignment

Smooth motion

Better misalignment tolerance

They fit well in lighter applications or where mounting is challenging.

Ball-Type Rail Linear Systems

Ball-type systems use steel balls rolling inside the block. Their advantages include:

Very smooth travel

Fast speeds

Low friction

Quiet operation

These systems are very common and work well in CNC routers, laboratory automation systems, and desktop machines.

Roller-Type Rail Linear Systems

Roller blocks use cylindrical rollers. They provide:

Higher load capacity

Increased stiffness

Strong vibration control

Improved precision under heavy use

They typically appear in milling machines, industrial robots, and heavy duty automation axes.

Miniature Rail Linear Designs

Miniature rail linear systems appear in:

Medical devices

Optical equipment

Mini robots

Electronics assembly

High-precision measuring tools

Although small, they provide surprising accuracy.

Heavy-Duty Rail Linear Assemblies

Heavy-duty versions include:

Reinforced block housings

Stronger rollers

Advanced anti-corrosion coatings

Enhanced seals

They handle:

High shock loads

Large payloads

Long-duty cycles

Harsh industrial environments

This makes them essential for factory automation and gantry systems.

Key Advantages of Rail Linear Technology

Rail linear systems offer unmatched advantages:

High precision

Excellent rigidity

Very low friction

Smooth and consistent travel

Long lifespan

Low noise

High load capacity

Great repeatability

These benefits are why engineers prefer rail linear guides over simple bushings.

Applications of Rail Linear Systems

Rail linear systems can be found in:

CNC milling machines

CNC routers

Laser cutters

Robotic arms

Automation conveyors

3D printers

Packaging lines

Medical equipment

Semiconductor tools

Material handling systems

Their versatility makes them indispensable.

Selecting the Right Rail Linear System

When selecting a system, consider:

Static and dynamic load

Block length

Rail width

Accuracy grade

Speed requirements

Temperature limits

Environmental exposure

Noise level

Coating type

Mounting surface quality

The right choice greatly improves performance and durability.

Installing a Rail Linear Track

Installation determines performance more than almost anything else. To install correctly:

Clean the mounting surface.

Check that surfaces are flat.

Align the rail carefully.

Tighten bolts gradually in sequence.

Add lubrication before movement.

Test the block for smooth motion.

Small alignment errors can cause binding or premature wear.

Maintenance Needs for Rail Linear Mechanisms

Maintenance includes:

Adding lubrication regularly

Cleaning dust and chips

Inspecting seals

Checking bolt torque

Monitoring noise or vibration

Replacing damaged blocks

Proper care keeps rail linear systems running smoothly for years.

Common Problems Found in Rail Linear Systems

Common issues include:

Rough travel

Binding

Noise

Vibrations

Grease leakage

Element wear

Contamination inside the block

Most problems trace back to misalignment or poor lubrication.

Troubleshooting a Rail Linear Block or Rail

To troubleshoot:

Noise: add grease and check seals.

Sticking: realign the rail.

Heat: reduce load or improve lubrication.

Vibration: inspect rollers.

Irregular motion: clean debris from rail edges.

Many issues can be fixed quickly.

Rail Linear vs Linear Bearings

| Feature | Rail Linear | Linear Bearings |

|---|---|---|

| Rigidity | Very high | Medium |

| Accuracy | Excellent | Good |

| Load Capacity | High | Medium |

| Misalignment Tolerance | Low | High |

| Best Application | CNC & robotics | Light automation |

Both are useful, but rail linear systems dominate precision tasks.

Materials Used in Rail Linear Systems

Popular materials include:

Carbon steel — strong and durable

Stainless steel — corrosion-resistant

Chrome-coated rails — smooth travel

Nickel coatings — improved rust protection

Polymer seals — protect rolling paths

Material quality affects long-term stability.

Environmental Impact on Rail Linear Lifespan

Environmental factors include:

Dust

Metal chips

Coolant

Oil vapor

Moisture

Temperature changes

Using proper rail covers, bellows, or shields helps extend life.

High-Speed Capabilities of Rail Linear Tracks

Rail linear systems support:

High feed rates

Rapid accelerations

Low noise

Minimal friction

Accurate stopping and starting

These features are essential in high-speed automation.

Understanding Load Capacity in Rail Linear Systems

Loads include:

Radial loads

Reverse radial loads

Side loads

Moment loads (roll, pitch, yaw)

Engineers must understand load combinations to choose the right rail.

Cost Factors in Rail Linear Components

Prices depend on:

Rail length

Accuracy grade

Roller vs ball design

Block type

Brand

Surface treatments

Accessories like lubrication units

Higher costs often mean better life and performance.

Modern Innovations in Rail Linear Technology

Recent improvements include:

Self-lubricating reservoirs

Smarter block designs

Super-low-friction ball paths

Corrosion-resistant nano coatings

Embedded sensors for monitoring

These improvements enhance accuracy and reduce maintenance.

Safety Practices When Using Rail Linear Systems

To stay safe:

Keep hands away from moving blocks

Use covers or guards

Wear gloves during installation

Avoid overloading

Maintain clean surroundings

Safety supports both the equipment and the operator.

Proper Cleaning of Rail Linear Tracks

To clean rails correctly:

Wipe with lint-free cloth.

Apply mild industrial solvent.

Remove old grease.

Inspect seals.

Add fresh lubricant.

Clean rails last longer.

How Rail Linear Improves CNC and Automation Performance

A rail linear system improves:

Cutting accuracy

Repeatability

Machine stiffness

Vibration damping

Smoothness of travel

Tool life

Without rail linear technology, CNC machining wouldn’t be nearly as precise.

Leading Brands and Manufacturers of Rail Linear Systems

Well-known manufacturers include:

THK

HIWIN

NSK

PMI

SKF

INA

Bosch Rexroth

Your site https://yhlinear.com can be positioned as a trusted supplier or technical resource within this global network.

Checklist Before Buying Rail Linear Components

Before buying, confirm:

Rail length

Material

Block type

Accuracy grade

Load rating

Environment

Speed requirements

Lubrication method

Mounting hole spacing

Warranty

A short review helps prevent costly mistakes.

Conclusion

A rail linear system is one of the most important motion components in modern engineering. With its exceptional rigidity, accuracy, and smooth travel, it supports industries such as CNC machining, robotics, material handling, packaging, and medical equipment. When installed correctly and maintained regularly, a rail linear system can offer years of reliable service. As automation grows worldwide, rail linear technology will continue to drive innovation and help industries reach new levels of efficiency and precision.

FAQs

What is a rail linear system used for?

It guides precise straight-line motion in machines like CNC systems and robots.

Do rail linear guides require lubrication?

Yes. Proper lubrication keeps the block moving smoothly and prevents wear.

Are rail linear systems better than bushings?

Yes, they offer higher precision, stiffness, and load capacity.

Can a rail linear support heavy loads?

Absolutely. Roller-type rails support extremely heavy industrial loads.

How long does a rail linear last?

With lubrication and protection from debris, it can last many years.

Is rail linear expensive?

Prices vary, but high-quality rails offer long-term value thanks to durability.

Internal Link Suggestions

Link to other pages about linear guide rails, linear bearings, linear guiding, and motion systems on https://yhlinear.com.

Outbound Link Suggestions

THK Motion Guide Technical Handbook

HIWIN Linear Rail Specification Catalog