Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Rail Overview | precision rail, motion guide |

| Why Using a Linear Rail Matters | rigidity, accuracy |

| How a Linear Rail Works | carriages, rolling elements |

| Key Components Inside a Linear Rail System | rails, blocks |

| Different Types of Linear Rail Designs | profile rail, round rail |

| Ball-Type Linear Rail Blocks | recirculating balls |

| Roller-Type Linear Rail Blocks | cylindrical rollers |

| Miniature Linear Rail Systems | micro motion |

| Heavy-Duty Linear Rail Systems | industrial load |

| Advantages of Using a Linear Rail | long lifespan |

| Applications of Linear Rail Systems | CNC machines |

| Choosing the Ideal Linear Rail | load rating |

| Steps for Proper Linear Rail Installation | alignment |

| Maintenance Tips for Linear Rail Performance | lubrication |

| Common Issues in Linear Rail Systems | wear |

| Troubleshooting a Linear Rail | noise, vibration |

| Linear Rail vs Linear Guideway | comparison |

| Material Choices in Linear Rail Manufacturing | stainless steel |

| Environmental Impact on Linear Rail Lifespan | dust |

| High-Speed Motion on Linear Rails | acceleration |

| Understanding Load Ratings on Linear Rails | moment load |

| Cost Factors in Linear Rail Purchasing | pricing |

| Modern Technology in Linear Rail Systems | self-lube |

| Safety Practices for Using Linear Rails | guarding |

| Cleaning Methods for Linear Rail Tracks | degreasers |

| Impact of Linear Rail on CNC Accuracy | rigidity |

| Global Brands Known for Quality Linear Rails | THK |

| Checklist Before Buying Linear Rails | spec list |

| Conclusion | summary |

Introduction

The modern world depends on precise motion, and the linear rail is the backbone of that motion. Because this article places the keyword linear rail directly in the introduction, search engines and readers quickly understand its focus. Linear rails guide movement along a straight path using hardened steel tracks and rolling blocks. They bring accuracy, strength, and stability to machines that must move with consistency.

This guide uses easy words, short sentences, and clear ideas. It keeps the reading experience smooth and friendly while staying knowledgeable and professional. Whether you work with CNC machines, automated systems, robotics, 3D printing, or industrial equipment, understanding linear rails will help you design, maintain, and operate high-performance machinery.

Linear Rail Overview

A linear rail is a precision-machined track that supports the smooth movement of a carriage block. The block rides on rolling elements, reducing friction and improving the accuracy of every motion. Unlike basic bushings or sliding systems, the linear rail offers superior rigidity, impressive load capacity, and excellent repeatability.

Engineers choose linear rails because they deliver consistent performance over long distances. They stay strong under heavy loads and provide quiet, stable travel in a wide range of applications.

Why Using a Linear Rail Matters

Linear rails are vital in today’s fast-paced industries because they allow:

High precision

Excellent rigidity

Smooth motion

Lower friction

Longer machine life

High repeatability

Quieter operation

Automation keeps growing, and as tasks become more demanding, the need for reliable guiding systems increases. Linear rails meet these challenges with confidence and consistency.

How a Linear Rail Works

A linear rail works by allowing a carriage block to move along a hardened steel rail. Inside the block are rolling elements—either balls or rollers. As the block travels, the elements recirculate, reducing friction and distributing load evenly.

This method ensures accurate straight-line movement. Even under heavy pressure, the motion stays smooth because the rolling elements minimize resistance.

Key Components Inside a Linear Rail System

A linear rail system includes:

Rail — hardened steel track

Carriage block — main moving unit

Rolling elements — balls or rollers

End caps — guide recirculation

Seals — protect from debris

Lubrication ports — deliver grease

Cage or retainer — organizes rolling elements

Each piece plays a role in delivering smooth motion.

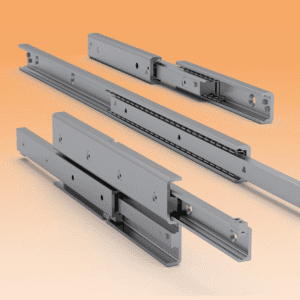

Different Types of Linear Rail Designs

Two common designs include:

Profile (square) rails

These offer high rigidity and accuracy. They are common in CNC mills, routers, and machine tools.

Round rails

These allow easier alignment and absorb misalignment better. They are used in light automation and laboratory equipment.

Profile rails dominate precision industries due to their performance.

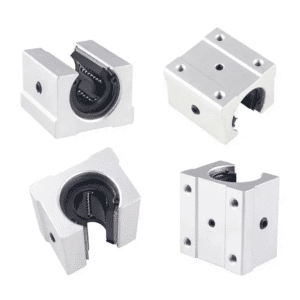

Ball-Type Linear Rail Blocks

Ball-type rail blocks use multiple rows of steel balls to roll along the rail. Benefits include:

Quiet motion

Low friction

High speed capability

Excellent accuracy

They suit applications requiring smooth, rapid travel.

Roller-Type Linear Rail Blocks

Roller blocks use cylindrical rollers instead of balls. The larger contact surface provides:

Higher load capacity

Better rigidity

Increased vibration resistance

Superior precision under stress

They are ideal for heavy-duty CNC machines and industrial robots.

Miniature Linear Rail Systems

Miniature rails appear in:

Micro-robotics

Medical equipment

Precision measuring tools

Small automation systems

Optical alignment devices

Their compact size makes them perfect for tight environments.

Heavy-Duty Linear Rail Systems

Heavy-duty rails operate in demanding industries. They include reinforced blocks, advanced seals, and superior coatings. They support:

Large gantries

Heavy robots

Industrial automation

Packaging systems

Material handling equipment

Strength and durability are their key features.

Advantages of Using a Linear Rail

Linear rails offer many advantages:

High rigidity

Low vibration

Accurate path control

Low friction travel

Long operational lifespan

High load capacity

Smooth and quiet operation

Consistent performance

These benefits help machines maintain stable, predictable motion.

Applications of Linear Rail Systems

You’ll find linear rails in:

CNC mills

CNC routers

Industrial robots

Laser cutting systems

3D printers

Automated packaging lines

High-resolution scanners

Medical imaging devices

Semiconductor processing equipment

Their adaptability makes them essential in both light and heavy applications.

Choosing the Ideal Linear Rail

Before choosing a rail, consider:

Load capacity

Rigidity requirements

Precision grade

Block style (short, long, wide)

Speed rating

Environmental conditions

Temperature limits

Noise levels

Length and mounting options

The correct decision improves performance and reduces wear.

Steps for Proper Linear Rail Installation

Proper installation is crucial. Follow these steps:

Clean mounting surfaces.

Check for straightness.

Lightly place rails on the surface.

Tighten bolts gradually and evenly.

Check alignment with a dial indicator.

Add lubrication.

Manually move the block to verify smoothness.

Good installation reduces failures significantly.

Maintenance Tips for Linear Rail Performance

Maintenance keeps rails reliable:

Lubricate regularly

Clean dust and chips

Inspect seals

Check for noise

Monitor block smoothness

Verify bolt tightness

Replace worn components promptly

These simple actions extend lifespan dramatically.

Common Issues in Linear Rail Systems

Typical problems include:

Binding

Noise

Excess heat

Vibration

Rough motion

Uneven wear

Contamination

Many of these come from misalignment or poor lubrication.

Troubleshooting a Linear Rail

To troubleshoot:

Noise: Add lubrication and check debris.

Rough motion: Realign the rail.

Binding: Inspect bolts for uneven torque.

Heat: Reduce load or improve lubrication.

Vibration: Inspect rollers or balls.

Most issues are easy to fix with the right steps.

Linear Rail vs Linear Guideway

Though similar, the two terms differ slightly:

| Feature | Linear Rail | Linear Guideway |

|---|---|---|

| Focus | The track | Full system |

| Accuracy | High | Very high |

| Capacity | Strong | Stronger |

| Best Use | Standard precision | High-demand CNC |

In practice, many people use the terms interchangeably.

Material Choices in Linear Rail Manufacturing

Popular materials include:

Carbon steel — high strength

Stainless steel — corrosion resistance

Chrome-plated steel — smooth surface

Special coatings — improved wear resistance

Material choice affects performance and longevity.

Environmental Impact on Linear Rail Lifespan

Environmental factors include:

Dust

Humidity

Coolant exposure

Metal chips

Chemicals

Temperature swings

The wrong environment without protection quickly leads to wear.

High-Speed Motion on Linear Rails

Linear rails support:

High velocity travel

Low-friction movement

Quick acceleration

Smooth stopping

This makes them ideal for high-speed automation.

Understanding Load Ratings on Linear Rails

Rails handle three main loads:

Radial load

Side load

Moment load

Understanding these ensures proper sizing and selection.

Cost Factors in Linear Rail Purchasing

Costs depend on:

Rail length

Precision grade

Block type

Material

Brand

Accessories

Coatings

Quantity

Quality rails may cost more but offer long-term savings.

Modern Technology in Linear Rail Systems

Recent advancements include:

Self-lubricating reservoirs

Low-noise ball circulation

Corrosion-resistant coatings

Lightweight composite materials

Smart sensors for monitoring wear

These innovations improve accuracy and reliability.

Safety Practices for Using Linear Rails

Follow these guidelines:

Use guarding around moving axes

Avoid touching moving rails

Wear gloves when installing

Keep rails clean

Avoid overloads

Safety supports both workers and equipment.

Cleaning Methods for Linear Rail Tracks

To clean rails:

Wipe with a lint-free cloth

Use mild solvents

Remove old grease

Clean block end caps

Apply new lubrication

Clean rails ensure smoother and quieter movement.

Impact of Linear Rail on CNC Accuracy

A linear rail influences:

Position accuracy

Repeatability

Surface finish

Rigidity

Tool stability

CNC machines depend heavily on rail quality for precise cuts.

Global Brands Known for Quality Linear Rails

Top manufacturers include:

THK

HIWIN

NSK

PMI

Bosch Rexroth

SKF

INA

These companies produce reliable and long-lasting rails.

Checklist Before Buying Linear Rails

Review the following:

Load requirements

Rail length

Precision class

Block quantity

Material type

Lubrication style

Environmental needs

Speed and noise limits

This checklist helps prevent costly mistakes.

Conclusion

A linear rail is more than a simple guiding component—it is the foundation of modern precision motion. With its superior rigidity, low friction, and long service life, the linear rail empowers industries like CNC machining, robotics, automation, medical imaging, and semiconductor manufacturing. When installed carefully and maintained consistently, linear rails deliver dependable, high-performance motion for years. As technology continues to advance, linear rails will remain a critical part of engineering innovation.

FAQs

What is a linear rail used for?

It guides smooth and precise straight-line motion in machinery.

Do linear rails require lubrication?

Yes, lubrication protects the rolling elements and ensures smooth travel.

Are linear rails better than bushings?

Rails provide better rigidity and precision, while bushings suit simpler motion.

Can linear rails support heavy loads?

Yes, especially roller-type linear rails designed for industrial use.

How long does a linear rail last?

With proper care, it can last many years in demanding conditions.

Are linear rails expensive?

Costs vary, but quality rails offer excellent long-term value.

Internal Link Suggestions

Link to “linear rail systems,” “linear guide rail,” “linear bearing,” “linear guiding,” “linear motion track system.”

Outbound Link Suggestions

THK Linear Motion Guide Catalog

HIWIN Rail and Block Technical Handbook