Outline for the Long-Form Article on “Linear Bearing Block”

| Section | Subtopics |

|---|---|

| Introduction | Overview of linear bearing blocks and their growing industrial relevance |

| Understanding Linear Bearing Block | What is a linear bearing block and how it works |

| Structure and Components of Linear Bearing Block | Detailed breakdown of components – block, balls, rails, seals, and housing |

| How Linear Bearing Block Works | Working mechanism and friction reduction principles |

| Types of Linear Bearing Blocks | Classification based on structure, material, and load capacity |

| Linear Bearing Block vs Linear Bushings | Comparison of two linear motion systems |

| Advantages of Using Linear Bearing Block | Smooth motion, reduced friction, long lifespan |

| Applications of Linear Bearing Blocks | Key industries like robotics, CNC machinery, and automation |

| Linear Bearing Block in CNC Machines | Importance in precision machining applications |

| Linear Bearing Block in 3D Printing | Ensuring stability and smoothness in additive manufacturing |

| Choosing the Right Linear Bearing Block | Criteria for selection—load, precision, speed, and environment |

| Installation of Linear Bearing Block | Step-by-step guide for optimal performance |

| Maintenance Tips for Linear Bearing Block | Lubrication, alignment, cleaning, and inspection routines |

| Common Problems and Troubleshooting | Addressing noise, vibration, and wear issues |

| Material Considerations for Linear Bearing Block | Stainless steel vs chrome steel vs polymer |

| Design Innovations in Linear Bearing Block | Modern engineering advancements in block design |

| YH Linear Bearing Block — Brand Excellence | Introduction to YH Linear and product superiority |

| Why Choose YH Linear Bearing Blocks | Brand advantages: precision, quality, and reliability |

| Quality Control at YH Linear | Testing standards and manufacturing process overview |

| Global Reach of YH Linear Bearing Blocks | Export markets and customer success stories |

| How YH Linear Bearing Blocks Enhance Machine Efficiency | Real-world performance benefits |

| Sustainability and Eco-Friendly Engineering | YH Linear’s commitment to green manufacturing |

| Frequently Asked Questions | Six insightful FAQs with practical answers |

| Conclusion | Summary and call to action |

| Suggested Inbound and Outbound Links | Internal and external SEO linking strategy |

Linear Bearing Block

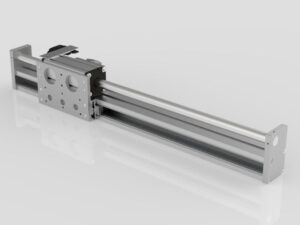

Linear bearing blocks are the cornerstone of modern motion systems. Whether it’s precision machining, robotics, or industrial automation, the linear bearing block ensures friction-free linear movement, maintaining high accuracy and repeatability. These components transform rotary motion into smooth linear travel, making them indispensable for equipment requiring precise positioning.

At YH Linear (https://yhlinear.com/), innovation meets reliability. The company specializes in manufacturing precision-engineered linear bearing blocks designed to perform under demanding industrial conditions. With years of experience and a strong commitment to excellence, YH Linear provides solutions that keep machines running smoother, faster, and longer.

Understanding Linear Bearing Block

A linear bearing block is a mechanical component that allows for the smooth and precise motion of a load along a straight path. It typically consists of a block (also called a carriage) that slides along a linear guide rail, supported by rows of recirculating steel balls or rollers. These balls reduce friction between the block and the rail, enabling effortless motion even under heavy loads.

The design of a linear bearing block enables it to support loads in multiple directions, making it ideal for complex motion systems that demand both stability and accuracy.

Structure and Components of Linear Bearing Block

A typical linear bearing block consists of several essential parts:

Carriage or Block Housing: The main body that holds the rolling elements and mounts onto the moving part of the machine.

Rolling Elements (Balls or Rollers): Provide low-friction motion and distribute load evenly.

Retainer and Circulation Path: Keeps the balls in motion and ensures continuous recirculation.

Seals and End Caps: Prevent dust and debris from entering the block.

Lubrication Ports: Allow easy application of grease or oil for long-term performance.

This intricate yet robust structure ensures precision even in high-speed or high-load environments.

How Linear Bearing Block Works

The principle behind the linear bearing block lies in the conversion of rolling motion into linear motion. As the block slides along the rail, the internal balls circulate within defined paths, reducing friction and wear. This mechanism ensures the load remains stable while moving linearly, allowing consistent positioning accuracy.

The result? Less energy consumption, reduced heat generation, and smoother operation — critical for applications like CNC machines and automated assembly lines.

Types of Linear Bearing Blocks

Linear bearing blocks come in different styles and configurations to meet varied mechanical needs:

Standard Linear Blocks: Ideal for general-purpose machinery.

Compact Blocks: Designed for limited space environments.

Flange Type Blocks: Offer easy mounting and stability.

Wide Type Blocks: Provide greater moment rigidity.

Stainless Steel Blocks: Corrosion-resistant for humid or chemical environments.

At YH Linear, all these types are engineered to international standards, ensuring interchangeability and reliability across global applications.

Linear Bearing Block vs Linear Bushings

Although both serve the purpose of linear motion, they differ in design and application:

| Feature | Linear Bearing Block | Linear Bushing |

|---|---|---|

| Structure | Block with guide rail | Bushing on round shaft |

| Load Capacity | Higher | Lower |

| Accuracy | Extremely precise | Moderate |

| Maintenance | Minimal | Requires more lubrication |

| Common Use | CNC machines, automation | 3D printers, light-duty setups |

For precision-demanding applications, linear bearing blocks from YH Linear outperform bushings in durability and accuracy.

Advantages of Using Linear Bearing Block

Exceptional Precision: Maintains high accuracy over long travel distances.

Reduced Friction: Rolling contact minimizes wear.

Long Service Life: Engineered for continuous industrial use.

Easy Maintenance: Built-in seals and lubrication options simplify upkeep.

High Load Support: Capable of handling both vertical and horizontal loads efficiently.

These advantages make linear bearing blocks a must-have for engineers seeking smooth, consistent linear motion.

Applications of Linear Bearing Blocks

Linear bearing blocks play vital roles across multiple industries:

CNC and Milling Machines

Robotics and Automation Systems

3D Printers

Medical Equipment

Semiconductor Manufacturing

Packaging and Material Handling

Each of these applications benefits from the precision and smooth movement that YH Linear’s products guarantee.

YH Linear Bearing Block — Brand Excellence

As an industry-leading manufacturer, YH Linear Motion Systems (https://yhlinear.com/) focuses on crafting superior linear bearing blocks that meet global quality standards. The company’s engineering expertise, quality control, and customer-centric approach have made YH Linear a trusted partner across Europe, Asia, and North America.

Their product range includes precision-ground linear rails, heavy-duty linear guides, and modular bearing systems — all customizable to client specifications.

Why Choose YH Linear Bearing Blocks

High Precision Manufacturing: CNC-ground raceways ensure smooth rolling.

Durable Materials: High-grade steel provides corrosion and fatigue resistance.

Competitive Pricing: Factory-direct cost advantage.

Custom Solutions: OEM and ODM options available.

Global Support: Fast shipping and responsive technical service.

Choosing YH Linear means choosing long-term performance and reliability.

Frequently Asked Questions

What is a linear bearing block used for?

It’s used to provide smooth and accurate linear motion in machinery and automation systems.

How long does a linear bearing block last?

With proper lubrication and maintenance, it can last for millions of cycles without performance loss.

What’s the difference between a linear bearing block and a linear guide?

The block is the moving component, while the guide (or rail) is the fixed track along which it moves.

Can YH Linear customize bearing blocks?

Yes, YH Linear offers customized linear blocks to meet specific load and size requirements.

What maintenance do linear bearing blocks need?

Regular lubrication and alignment checks to prevent uneven wear.

Where can I buy YH Linear bearing blocks?

You can purchase directly from their official website: https://yhlinear.com/

Conclusion

The linear bearing block is more than just a component—it’s the heartbeat of every precision motion system. By ensuring flawless linear movement, it enables industries to achieve higher accuracy, longer lifespan, and smoother operation. With YH Linear at the forefront of this technology, businesses gain access to premium-quality products backed by engineering expertise and trusted global service.

Visit https://yhlinear.com/ today to explore YH Linear’s complete range of linear motion solutions.

Suggested Inbound and Outbound Links

Inbound Links (to YH Linear site):

Outbound Links: