Outline for the Article

| Main Headings | Sub-Headings |

|---|---|

| Introduction to Linear Motion Bearing Block | Importance in precision motion |

| What is a Linear Motion Bearing Block | Definition and concept |

| History of Linear Motion Bearing Technology | From early bearings to modern blocks |

| How a Linear Motion Bearing Block Works | Principles of operation |

| Key Components of a Linear Motion Bearing Block | Carriage, housing, rolling elements |

| Types of Linear Motion Bearing Blocks | Ball-type, roller-type, miniature |

| Linear Motion Bearing Block vs Linear Guide Block | Differences explained |

| Advantages of Linear Motion Bearing Blocks | Efficiency, precision, durability |

| Disadvantages of Linear Motion Bearing Blocks | Cost, contamination, maintenance |

| Applications in CNC Machines | Machining and tooling |

| Linear Motion Bearing Block in 3D Printing | Accuracy and stability |

| Industrial Applications | Aerospace, automotive, packaging |

| Robotics and Automation | Role in robotic arms and cobots |

| Material Choices for Bearing Blocks | Steel, stainless steel, aluminum |

| Design Variations of Bearing Blocks | Flange type, compact, heavy-duty |

| Installation of Linear Motion Bearing Blocks | Steps for proper mounting |

| Lubrication and Maintenance | Keeping performance smooth |

| Common Problems with Bearing Blocks | Noise, play, and wear |

| Troubleshooting Linear Motion Bearing Blocks | Preventive and corrective actions |

| Innovations in Bearing Block Technology | Smart bearings, IoT sensors |

| Future of Linear Motion Bearing Blocks | Industry 4.0 and AI integration |

| Cost Factors of Bearing Blocks | Budget vs high-end options |

| Durability and Lifespan | How long they last |

| Top Manufacturers | Leading global brands |

| Linear Motion Bearing Block vs Plain Bearing | Choosing the right one |

| Environmental Considerations | Sustainability in materials |

| Conclusion | Summary and insights |

| FAQs | Commonly asked questions |

Introduction to Linear Motion Bearing Block

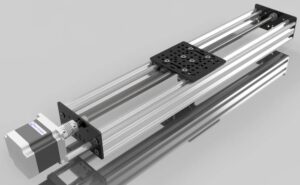

Every modern machine that requires precision motion depends on specialized components to move smoothly and accurately. One such component is the linear motion bearing block. Found in CNC machines, robotics, 3D printers, and countless other systems, this device plays a vital role in guiding and supporting linear movement.

Without bearing blocks, friction would wear out machine parts quickly, reducing accuracy and efficiency. With them, industries achieve consistent, reliable, and long-lasting performance.

What is a Linear Motion Bearing Block

A linear motion bearing block is a carriage-like structure that slides along a linear rail using rolling elements such as steel balls or rollers. Its purpose is to support loads while enabling friction-reduced, precise linear motion.

Think of it as a train carriage moving smoothly on tracks, but at the micro-precision level required in engineering and automation.

History of Linear Motion Bearing Technology

Early Era: Simple grooves and sliding wood structures.

Industrial Revolution: Introduction of metal-on-metal bearings.

20th Century: Ball bearings revolutionized precision engineering.

Modern Day: Compact bearing blocks integrated with linear rails dominate CNC, robotics, and aerospace industries.

How a Linear Motion Bearing Block Works

The principle is straightforward:

A rail provides the path.

The bearing block carries the load.

Rolling elements inside the block minimize friction.

As the block moves, balls or rollers circulate continuously, enabling smooth travel.

This allows precise positioning, stability, and high load capacity.

Key Components of a Linear Motion Bearing Block

Block Housing: The rigid body that contains all elements

Rolling Elements: Balls or rollers circulating inside

End Caps: Keep rolling elements in circulation

Seals: Prevent dirt and dust contamination

Mounting Holes: For attaching loads or fixtures

Types of Linear Motion Bearing Blocks

Ball Bearing Blocks – Standard type, smooth, cost-efficient

Roller Bearing Blocks – Handle heavier loads, more rigid

Miniature Bearing Blocks – Compact, used in electronics and 3D printers

Flanged Bearing Blocks – Wider mounting surface for stability

Linear Motion Bearing Block vs Linear Guide Block

Linear Motion Bearing Block: Refers specifically to the block itself, carrying loads and moving along the rail.

Linear Guide Block: Refers to the combined system of rail + block.

Advantages of Linear Motion Bearing Blocks

High Precision: Supports micrometer-level accuracy

Durability: Long service life with proper care

Load Capacity: Can handle both radial and axial forces

Smooth Operation: Reduced friction compared to sliding contact

Versatility: Suitable for multiple industries

Disadvantages of Linear Motion Bearing Blocks

Higher Cost than plain bearings

Requires Maintenance (lubrication, cleaning)

Sensitive to Contamination if seals fail

Installation Precision Needed – Misalignment causes wear

Applications in CNC Machines

Bearing blocks are essential in CNC systems for:

Tool movement with precision

Heavy-load machining

Repetitive, high-speed operations

Without them, CNC machines would lose accuracy and efficiency.

Linear Motion Bearing Block in 3D Printing

For 3D printers, bearing blocks ensure:

Accurate print head positioning

Reduced vibration

Smoother layering process

This results in higher-quality prints.

Industrial Applications

Aerospace: Aircraft part assembly and alignment

Automotive: Robotic welding and manufacturing

Packaging: Fast, repetitive linear motion

Medical: Imaging machines, surgical robots

Robotics and Automation

In robotics, bearing blocks are critical for:

Arm extension and retraction

Pick-and-place systems

Cobots (collaborative robots) for factories

Material Choices for Bearing Blocks

Carbon Steel: Durable, cost-effective, rust-prone

Stainless Steel: Corrosion-resistant, ideal for clean environments

Aluminum: Lightweight, used in smaller applications

Composite Materials: Advanced, lightweight applications

Design Variations of Bearing Blocks

Compact Blocks – Space-saving designs

Heavy-Duty Blocks – For large industrial machinery

Flanged Blocks – Easier mounting and wider load distribution

Installation of Linear Motion Bearing Blocks

Steps for installation:

Clean rail and mounting surfaces

Align rails precisely

Slide blocks onto the rail carefully

Tighten screws to manufacturer’s torque settings

Test for smooth motion

Lubrication and Maintenance

Apply grease or oil regularly

Inspect seals and replace if worn

Keep rails clean from dust

Follow manufacturer’s lubrication intervals

Common Problems with Bearing Blocks

Noise – Usually from lack of lubrication

Play or Looseness – Indicates internal wear

Misalignment – Causes uneven movement

Contamination – Dust or debris inside the block

Troubleshooting Linear Motion Bearing Blocks

Add lubrication for smoother motion

Replace damaged seals to prevent contamination

Realign rails if motion feels uneven

Replace blocks if excessive play develops

Innovations in Bearing Block Technology

Self-lubricating materials reduce maintenance

Smart sensors detect wear and load changes

IoT-enabled systems allow predictive maintenance

Lightweight alloys improve efficiency

Future of Linear Motion Bearing Blocks

The future includes:

AI-powered monitoring for predictive servicing

Eco-friendly materials for sustainability

Nanometer-level precision for electronics

Greater automation integration

Cost Factors of Bearing Blocks

Entry-level blocks: $20–$50

Mid-range industrial blocks: $100–$300

High-precision blocks: $500+

Durability and Lifespan

On average, a linear motion bearing block lasts 5–10 years, depending on:

Load

Speed

Maintenance

Environment

Top Manufacturers

THK (Japan)

HIWIN (Taiwan)

NSK (Japan)

Bosch Rexroth (Germany)

SKF (Sweden)

Linear Motion Bearing Block vs Plain Bearing

Bearing Block: High precision, low friction, heavy-duty

Plain Bearing: Low cost, simpler design, less precise

Environmental Considerations

Manufacturers are adopting:

Recyclable materials

Lubrication-free designs

Energy-efficient production

Conclusion

A linear motion bearing block is a vital component in modern engineering, enabling smooth, precise, and durable linear motion across industries. From CNC machining to 3D printing and robotics, it plays an irreplaceable role in achieving efficiency and accuracy.

As technology advances, bearing blocks will become smarter, more durable, and eco-friendly, making them a cornerstone of Industry 4.0.

FAQs

What is a linear motion bearing block used for?

It is used to guide machine parts along a rail with precision, supporting heavy loads and reducing friction.

How long do bearing blocks last?

Typically 5–10 years with proper care.

Do linear motion bearing blocks need lubrication?

Yes, lubrication is essential for smooth, long-lasting performance.

What’s the difference between bearing blocks and plain bearings?

Bearing blocks use rolling elements for precision, while plain bearings slide directly on a surface.

Are they expensive?

Costs range from affordable hobbyist versions to expensive industrial-grade models.

Which industries rely most on bearing blocks?

CNC machining, aerospace, automotive, packaging, and robotics.

Inbound Link Suggestions

Link to “What is a Linear Guide”

Link to “Linear Tracks Explained”

Link to “CNC Machine Components”