Outline for the Article

| Main Headings | Sub-Headings |

|---|---|

| Introduction to Low Cost Linear Guide | Why affordability matters in engineering |

| What is a Low Cost Linear Guide | Definition and importance |

| History of Linear Guides | From premium systems to budget-friendly options |

| How a Linear Guide Works | Basic principle explained |

| Key Components of Low Cost Linear Guide | Rail, block, rolling elements |

| Types of Low Cost Linear Guides | Ball-type, roller-type, miniature |

| Low Cost Linear Guide vs Standard Linear Guide | Key differences |

| Advantages of Low Cost Linear Guides | Affordability, accessibility |

| Disadvantages of Low Cost Linear Guides | Limitations and risks |

| Applications in DIY Projects | Hobby CNC, 3D printers |

| Applications in Industrial Use | When budget solutions are suitable |

| CNC Machines and Low Cost Linear Guides | Practical considerations |

| 3D Printing with Low Cost Guides | Accuracy and performance |

| Robotics and Automation | Entry-level robotic systems |

| Material Options for Low Cost Guides | Steel, aluminum, composites |

| Design Variations in Affordable Guides | Miniature, compact, flanged |

| Installation of Low Cost Linear Guides | Step-by-step process |

| Lubrication and Maintenance | Keeping costs low over time |

| Common Problems with Low Cost Linear Guides | Wear, noise, misalignment |

| Troubleshooting Affordable Linear Guides | Easy fixes |

| Innovations in Budget Linear Guide Technology | New materials and designs |

| Future of Low Cost Linear Guides | Accessibility in Industry 4.0 |

| Cost Analysis of Linear Guides | Budget vs high-performance |

| How to Choose a Low Cost Linear Guide | Selection tips |

| Top Affordable Linear Guide Brands | Market leaders |

| Low Cost Linear Guide vs DIY Linear Rail | Which one to choose |

| Environmental Impact of Budget Guides | Sustainable designs |

| Conclusion | Summary and outlook |

| FAQs | Commonly asked questions |

Introduction to Low Cost Linear Guide

Precision motion has always been associated with high costs. In the past, linear guides were considered expensive components used only in top-tier industrial systems. But with advancements in materials, manufacturing, and global competition, the rise of the low cost linear guide has changed the game.

These affordable alternatives now make precision motion accessible not only to large industries but also to small businesses, startups, and hobbyists. Whether you’re building a CNC router in your garage or optimizing an entry-level automation system, budget-friendly linear guides can provide an excellent balance between price and performance.

What is a Low Cost Linear Guide

A low cost linear guide is essentially a simplified or budget-friendly version of a linear motion system that provides smooth, controlled, and reliable linear movement without the premium price tag.

They usually consist of a steel or aluminum rail and a carriage block with rolling elements like balls or rollers that reduce friction. While they may not match high-end guides in durability and load capacity, they are good enough for many applications, especially in light to medium-duty projects.

History of Linear Guides

Early mechanical systems: Sliding wood or bronze bearings with high friction.

Industrial revolution: Steel bearings and rails increased efficiency.

Mid-20th century: Introduction of ball bearings reduced wear.

Modern era: High-precision, expensive guides dominated industrial markets.

Present day: Affordable manufacturing in Asia led to mass availability of low cost linear guides, balancing performance with budget needs.

How a Linear Guide Works

The mechanism is simple:

A rail provides the straight path.

A bearing block or carriage moves along the rail.

Inside the block, rolling elements reduce friction.

This allows precise and smooth linear movement, even under load.

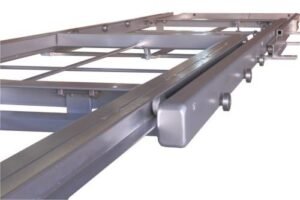

Key Components of Low Cost Linear Guide

Guide Rail: Usually steel or aluminum.

Bearing Block: Moves along the rail, carrying loads.

Rolling Elements: Balls or rollers that ensure low-friction movement.

Seals and End Caps: Protect from dust and debris.

Mounting Holes: Allow easy attachment.

Types of Low Cost Linear Guides

Ball-Type Guides: Affordable, smooth, widely available.

Roller-Type Guides: Handle higher loads, slightly more expensive.

Miniature Guides: Compact, used in electronics and 3D printing.

Low Cost Linear Guide vs Standard Linear Guide

| Feature | Low Cost Linear Guide | Standard Linear Guide |

|---|---|---|

| Price | Affordable | Expensive |

| Precision | Moderate | High |

| Load Capacity | Light to medium | Heavy |

| Durability | Lower | Long-lasting |

| Applications | DIY, light industry | Aerospace, automotive, CNC machining |

Advantages of Low Cost Linear Guides

Budget-Friendly – Perfect for startups and hobbyists.

Widely Available – Easily sourced online.

Lightweight Applications – Ideal for 3D printers, small CNCs.

Simple Installation – Easy to mount and replace.

Disadvantages of Low Cost Linear Guides

Lower Durability – Wear out faster.

Less Precision – Not suitable for nanometer-level accuracy.

Limited Load Capacity – Can’t handle heavy industrial loads.

Maintenance Required – Needs regular lubrication.

Applications in DIY Projects

Hobbyists and makers love low cost linear guides for:

CNC routers

Laser cutters

3D printers

Small automation systems

They make precision affordable for personal projects.

Applications in Industrial Use

Even in industries, low cost linear guides can be used in:

Packaging lines

Pick-and-place systems

Light assembly lines

They are not meant for aerospace or heavy machining but serve well in secondary processes.

CNC Machines and Low Cost Linear Guides

Budget-friendly CNC machines often use low cost linear guides. They provide sufficient precision for woodworking, plastics, and light metal work. For heavy machining, however, premium guides are still necessary.

3D Printing with Low Cost Guides

In 3D printers, low cost guides:

Reduce vibrations

Improve accuracy

Enhance print quality

They have become the standard in most desktop printers.

Robotics and Automation

Low cost guides are commonly used in:

Entry-level robotic arms

DIY automation projects

Educational robotics kits

They keep costs low while providing sufficient motion precision.

Material Options for Low Cost Guides

Carbon Steel – Cheap but prone to rust.

Aluminum – Lightweight, good for small projects.

Composites – Durable, used in special cases.

Design Variations in Affordable Guides

Miniature Guides – Compact for electronics.

Flanged Blocks – Wider mounting surfaces.

Compact Blocks – Space-saving designs.

Installation of Low Cost Linear Guides

Steps:

Clean the surface.

Mount the rail with screws.

Attach the block carefully.

Test motion for smoothness.

Lubrication and Maintenance

Use grease or oil regularly.

Clean rails from dust.

Replace seals if worn.

Check alignment frequently.

Common Problems with Low Cost Linear Guides

Noise – Caused by lack of lubrication.

Wear – Faster in cheap materials.

Play – Looseness over time.

Rusting – In low-quality steel.

Troubleshooting Affordable Linear Guides

Apply fresh lubrication.

Realign the rails.

Replace worn-out blocks.

Protect from dust and humidity.

Innovations in Budget Linear Guide Technology

Self-lubricating designs

Improved coatings for rust resistance

Compact designs for portable devices

Hybrid materials for better performance

Future of Low Cost Linear Guides

Wider adoption in small businesses

Eco-friendly materials

Integration with smart systems

Improved lifespan at lower prices

Cost Analysis of Linear Guides

Low cost linear guides: $10 – $100

Mid-range industrial: $100 – $300

Premium precision: $500+

How to Choose a Low Cost Linear Guide

Define your application load and speed.

Pick the right material.

Choose the correct size and mounting type.

Balance cost vs expected lifespan.

Top Affordable Linear Guide Brands

HIWIN (budget series)

LDO Motors (3D printing)

RobotDigg

Generic Chinese suppliers (Amazon, AliExpress, Banggood)

Low Cost Linear Guide vs DIY Linear Rail

Low Cost Guide: Ready-made, smoother, reliable.

DIY Rail: Cheaper, but less precise, time-consuming.

Environmental Impact of Budget Guides

Recyclable metals help reduce waste.

Cheap coatings may increase pollution.

Future designs aim for sustainable materials.

Conclusion

The low cost linear guide is a game-changer for engineers, makers, and industries alike. While not as durable or precise as premium systems, they provide an affordable entry point into precision motion technology.

For DIY projects, light industry, and budget automation, low cost guides strike a perfect balance between price, performance, and accessibility.

FAQs

What is a low cost linear guide used for?

It is used in CNC, 3D printing, robotics, and packaging systems where affordability matters.

Are low cost linear guides reliable?

Yes, for light-duty projects. They are not recommended for heavy industrial use.

Do they need lubrication?

Yes, lubrication improves lifespan and performance.

Where can I buy them?

Online stores like Amazon, AliExpress, and industrial suppliers.

What’s the price range?

Typically between $10 and $100 depending on size and brand.

Can they be used in robotics?

Yes, especially in educational and entry-level robotics.